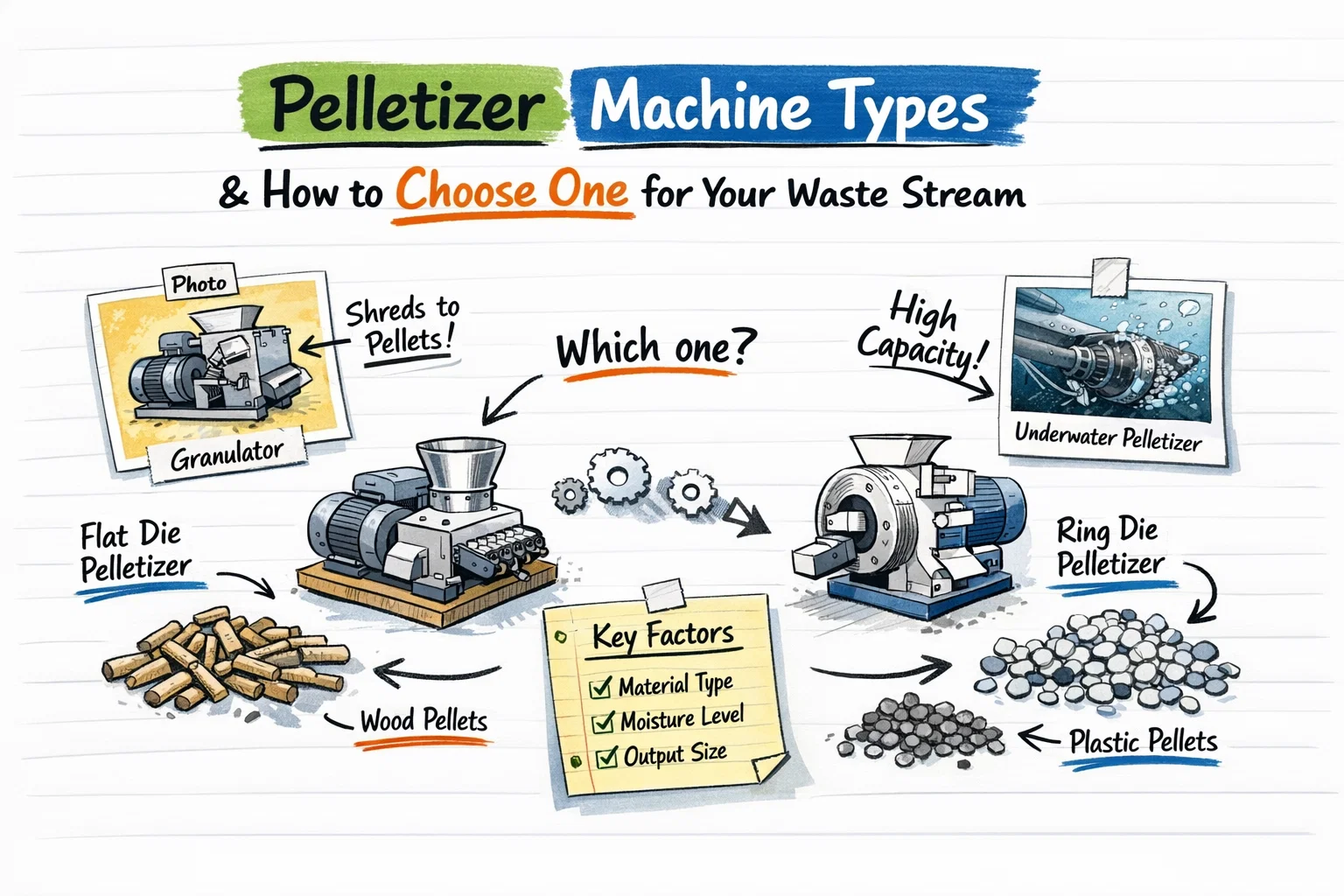

Pelletizer Machine Types: The Complete Guide to Choosing the Right One

Investing in the wrong pelletizer machine types is the most common—and expensive—mistake we see in the plastic recycling industry. You might have a warehouse full of valuable LDPE film, but if you feed it into a standard single-screw extruder designed for rigid pipes, you are going to face constant surging, low output, and degraded pellets.

At Rumtoo, we believe that your waste stream dictates your machine, not the other way around. Whether you are dealing with post-industrial film, rigid HDPE regrind, or PET flakes, the profitability of your operation hangs on matching the “form” of your waste to the physics of the extruder.

This guide cuts through the technical noise to help you understand exactly which pelletizing technology fits your specific recycling goals.

1. The Feed: Handling the “Form” Factor

Before plastic even hits the screw, it must enter the machine. This is where 80% of processing issues occur. The density of your material—whether it is fluffy film or heavy chips—determines the feeding technology you need.

For Light, Soft Plastics (Films, Bags, Raffia)

If you recycle PE/PP films, woven bags, or foamed materials, you face a density problem. These materials are too light to drop into a screw naturally.

The Solution: Cutter Compactor Integrated Lines

Also known as a “3-in-1” system (like our ReadyMac series), this machine combines a cutter compactor directly with the extruder screw.

- Cómo funciona: A large pot at the base of the machine cuts, dries, and friction-heats the plastic until it densifies. Centrifugal force then pushes this hot, dense material directly into the extruder screw.

- Why you need it: It eliminates the need for a separate agglomerator and ensures the screw is always full, preventing “surging” (uneven output).

For Heavy, Rigid Plastics (Regrind, Flakes)

If you process crushed bottles, pipes, crates, or ABS electronic waste, your material is already dense enough to flow by gravity.

The Solution: Hopper or Force Feeder Systems

A standard hopper often works for free-flowing regrind. However, if you are mixing light and heavy materials, a side-force feeder helps push material into the screw to maintain high throughput.

2. The Engine: Single vs. Twin Screw Extruders

Once the plastic is inside, it needs to be melted and pressurized. The debate between single and twin screws is often misunderstood.

Single Screw Extruder (The Workhorse)

The vast majority of recycling jobs—especially for PE and PP—use single-screw extruders. They are excellent at generating the high pressure needed to push dirty plastic through fine filtration screens. They are cost-effective, easy to maintain, and energy-efficient for materials that don’t require complex mixing.

Twin Screw Extruder (The Mixer)

Twin screws utilize two intermeshing screws. You generally need this for:

- Compounding: Adding fillers (like Calcium Carbonate) or reinforcing fibers.

- PET Recycling: PET requires careful handling of moisture and viscosity (IV), which twin screws manage better through superior vacuum degassing capabilities.

- Sensitive Materials: If you need precise temperature control to prevent degradation.

3. The Cut: Water Ring vs. Strand Pelletizing

How you cut the plastic determines the shape and quality of your final product. This choice depends heavily on the polymer’s “melt strength.”

Water Ring (Die Face) Pelletizing

This is the industry standard for PE and PP recycling.

- Proceso: Blades cut the plastic immediately as it exits the die head, and the pellets are instantly flung into a cooling water ring.

- Mejor para: Polyethylene (PE) and Polypropylene (PP). These materials can stick together if not cooled quickly.

- Advantage: It is highly automated. Even if a blade gets dull, the machine keeps running. It’s compact and reduces labor costs.

Pelletización de Hilos

This is the traditional “spaghetti” method. Plastic strands are pulled through a water bath and then cut by a granulator.

- Mejor para: Engineering plastics (ABS, PC), PET, and high-MFI materials (very runny plastics) that might smear on a die face cutter.

- Advantage: Produces very cylindrical, high-quality pellets that look like virgin material.

- Disadvantage: Strands can break, requiring an operator to manually re-thread them. It requires more floor space for the cooling bath.

4. The Decision Matrix: Matching Material to Machine

To simplify your buying decision, we have mapped common waste streams to the ideal machine configuration found on our product page.

| Waste Stream | Recommended Feed | Screw Type | Método de Pelletización |

|---|---|---|---|

| PE/PP Films (Washed) | Compactador con Cortador | Monotornillo | Anillo de Agua |

| Rigid HDPE/PP (Bottles, Pipes) | Hopper / Force Feeder | Monotornillo | Strand or Water Ring |

| PET Flakes (Bottles) | Force Feeder + Crystallizer | Doble Tornillo | Varilla |

| PVC (Soft or Rigid) | Hopper | Conical Twin / Single | Die Face (Air Cooled) |

| Compounding (Adding Fillers) | Side Feeder | Doble Tornillo | Varilla |

5. Critical Factors Beyond the Spec Sheet

When comparing manufacturers, look beyond the motor size. The efficiency of a recycling line is often determined by two “hidden” systems: Filtration and Degassing.

Filtration (Screen Changers)

Post-consumer waste is dirty. If you use a manual screen changer, your operator will stop the machine every 30 minutes to swap screens, killing your efficiency.

Busque dual-piston continuous screen changers or laser filters. These allow the machine to keep running while the screen cleans itself or while one piston is being changed. This non-stop operation is vital for profitability.

Degassing (Venting)

Moisture is the enemy. Ink and water turn into gas inside the extruder, creating porous, “foamy” pellets that buyers reject.

Ensure your machine has high-efficiency vacuum degassing zones. For heavily printed films, a double-venting system is often necessary to remove the high volume of volatiles released during melting.

Summary

Choosing the right pelletizer is not about finding the cheapest machine; it is about finding the machine that can handle your material’s worst days (contamination, moisture) while delivering consistent output.

If you are processing film, the Compactador con Cortador is your best friend. If you are handling rigid regrind, a robust Monotornillo with a good screen changer will serve you for decades.

For a deeper dive into specific machinery specs and to see these systems in action, visit Rumtoo Recycling Machinery. We configure lines based on your specific sample material to ensure zero surprises upon installation.