Recycling highly printed plastic films—such as polyethylene (PE), polypropylene (PP), and biaxially oriented polypropylene (BOPP)—requires advanced equipment and specialized processes. These materials often contain inks, coatings, and contaminants that can compromise the quality of recycled pellets if not properly removed. Below is an in-depth look at effective recycling solutions for printed films in industrial settings.

Challenges in Recycling Printed PE and PP Films

Printed PE and PP films pose significant challenges:

- Ink and coating residues degrade the quality of the recycled polymer.

- Lightweight and flexible film structures can tangle in conventional machinery.

- Contaminants such as dirt, labels, adhesives, and other plastics must be thoroughly removed to ensure pellet integrity.

Industrial Film Recycling Process

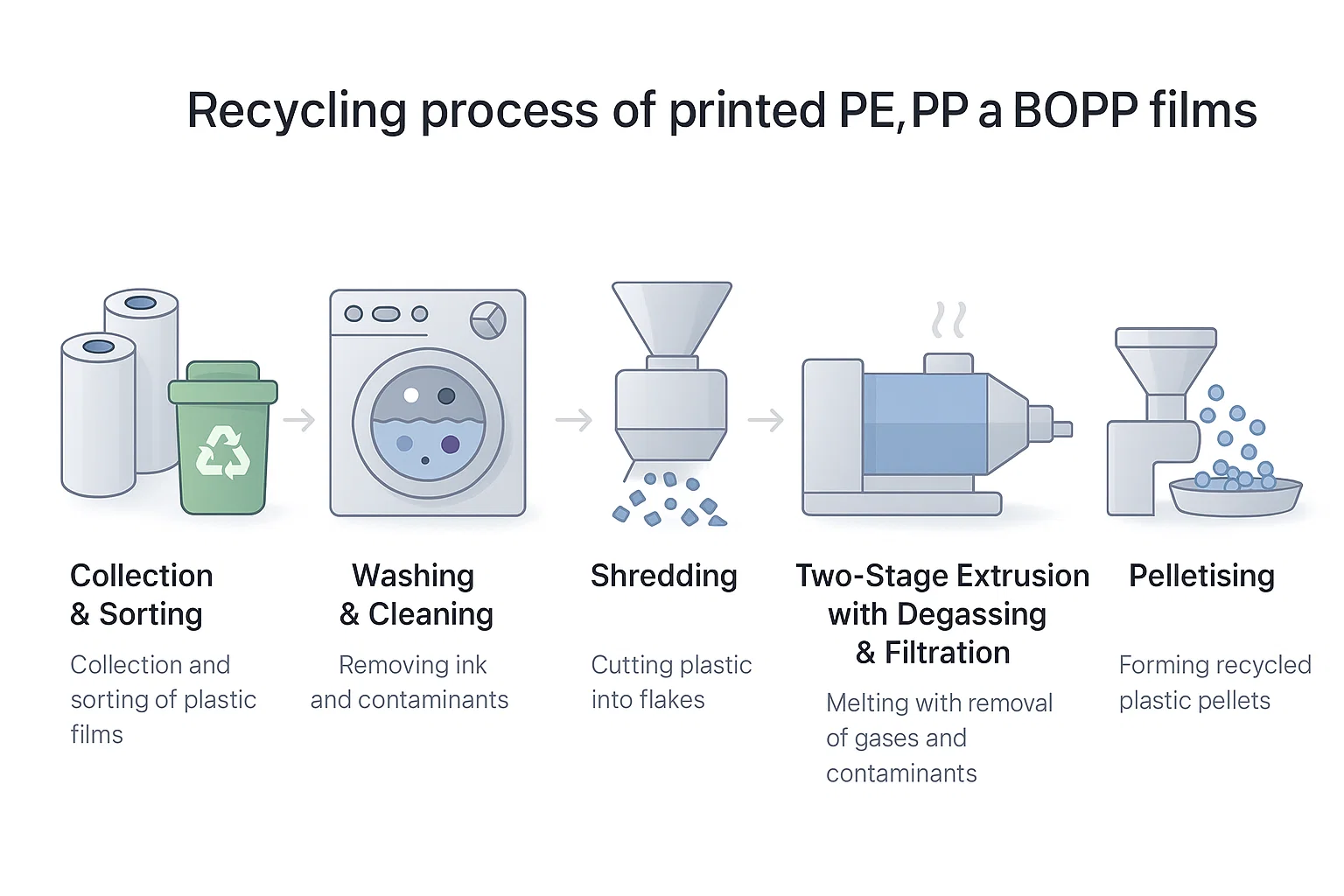

1. Collection and Sorting

Films are sourced from post-consumer waste, industrial scrap, or agricultural use. Sorting by polymer type (PE vs. PP), and occasionally by color, is essential to achieve material uniformity and reduce cross-contamination.

2. Washing and Decontamination

A robust washing process removes surface contaminants such as soil, food residue, adhesives, and loose inks. This step is critical for achieving clean input material.

3. Shredding and Preprocessing

Films are shredded into flakes to prepare them for extrusion. Pre-cutting increases surface area and aids in consistent melting and filtration.

4. Two-Stage Extrusion with Advanced Degassing

Cutting-edge systems like Repro-Flex Plus utilize a two-stage extruder equipped with:

- Multiple degassing zones to eliminate volatile ink residues and moisture.

- High-performance filtration units to remove fine impurities and coatings.

- Integrated cutter-compactor that agglomerates and feeds film flakes directly, improving output stability and energy efficiency.

5. Pelletising

The clean, filtered melt is converted into uniform, high-quality pellets that are ready for direct reuse in manufacturing, such as blown film or injection molding applications.

Advantages of Advanced Recycling for PE and PP Films

- High-quality recycled pellets are suitable for demanding applications.

- Lower energy consumption compared to traditional single-stage systems.

- Capability to process laminated and multilayer films, previously considered non-recyclable.

Recycling Printed and Metallised BOPP Films

Unique Challenges of BOPP Recycling

BOPP films often feature printed surfaces and metalized layers, complicating recycling. The base PP layer must be preserved while effectively stripping away inks and metal coatings.

Advanced BOPP Recycling Equipment

Recycling systems specifically designed for BOPP—such as enhanced versions of Repro-Flex Plus—feature:

- Additional extruders and filtration units to tackle heavy ink loads and metallization.

- Extended degassing capabilities to minimize thermal degradation and odor formation.

Innovations in BOPP Recycling

The adoption of PU-based printing inks has significantly improved recycling outcomes:

- Enables production of color-stable, odorless, and defect-free recyclates.

- Suitable for reuse in flat films and thermoformed packaging without major process adjustments.

Applications for Recycled BOPP

Recycled BOPP granules are commonly used in:

- Packaging films and labels

- Adhesive tapes

- Thermoformed trays and containers

Notably, using recycled BOPP can reduce heating energy consumption during thermoforming by up to 20%, especialmente con reciclados más oscuros debido a su superior absorción de calor.

Resumen: Comparativa del Reciclaje de PE, PP y BOPP

AspectoPelículas de PE y PPPelículas de BOPP

Desafíos Clave Eliminación de tinta, contaminación, enredos de materialCapas metalizadas, complejidad de la tinta

Requisitos de Clasificación Por polímero y colorÉnfasis en el polímero base de PP

Equipo Recomendado Extrusor de dos etapas con compactador y filtrosExtrusión multietapa con filtración extendida

Eliminación de Tinta Mediante desgasificación y filtración multizonaMejorada con compatibilidad para tintas PU

Calidad del Pellet Uniforme, versátil, de alta calidadInodoro, estable en color, fácil de procesar

Aplicaciones Típicas Películas, componentes moldeadosPelículas, etiquetas, productos termoformados

Ahorro de Energía/Costos Energía reducida, rendimiento optimizadoAhorros energéticos de hasta 20% en termoformado

Notas sobre el Reciclaje de Películas Delgadas en Canales Minoristas

Los programas de recolección minorista para películas delgadas de PE y PP generalmente dependen de lo siguiente:

- Contenedores de entrega para películas limpias y secas en tiendas participantes.

- Métodos de reciclaje mecánico (trituración, lavado, extrusión, peletizado), que replican procesos industriales pero a menor escala.

Reflexiones Finales

El reciclaje efectivo de películas de PE, PP y BOPP altamente impresas depende de la integración de extrusores multietapa avanzados con sistemas robustos de desgasificación y filtración. Tecnologías como Repro-Flex Plus han transformado la viabilidad del reciclaje de materiales complejos, permitiendo la producción de pellets de alta calidad que respaldan circular economy y mejoran la sostenibilidad ambiental en las industrias de procesamiento de plásticos.

Avísame si deseas adaptar esto a un formato HTML, texto para folleto, o contenido para página de destino, o si prefieres localizarlo para un segmento de mercado específico.