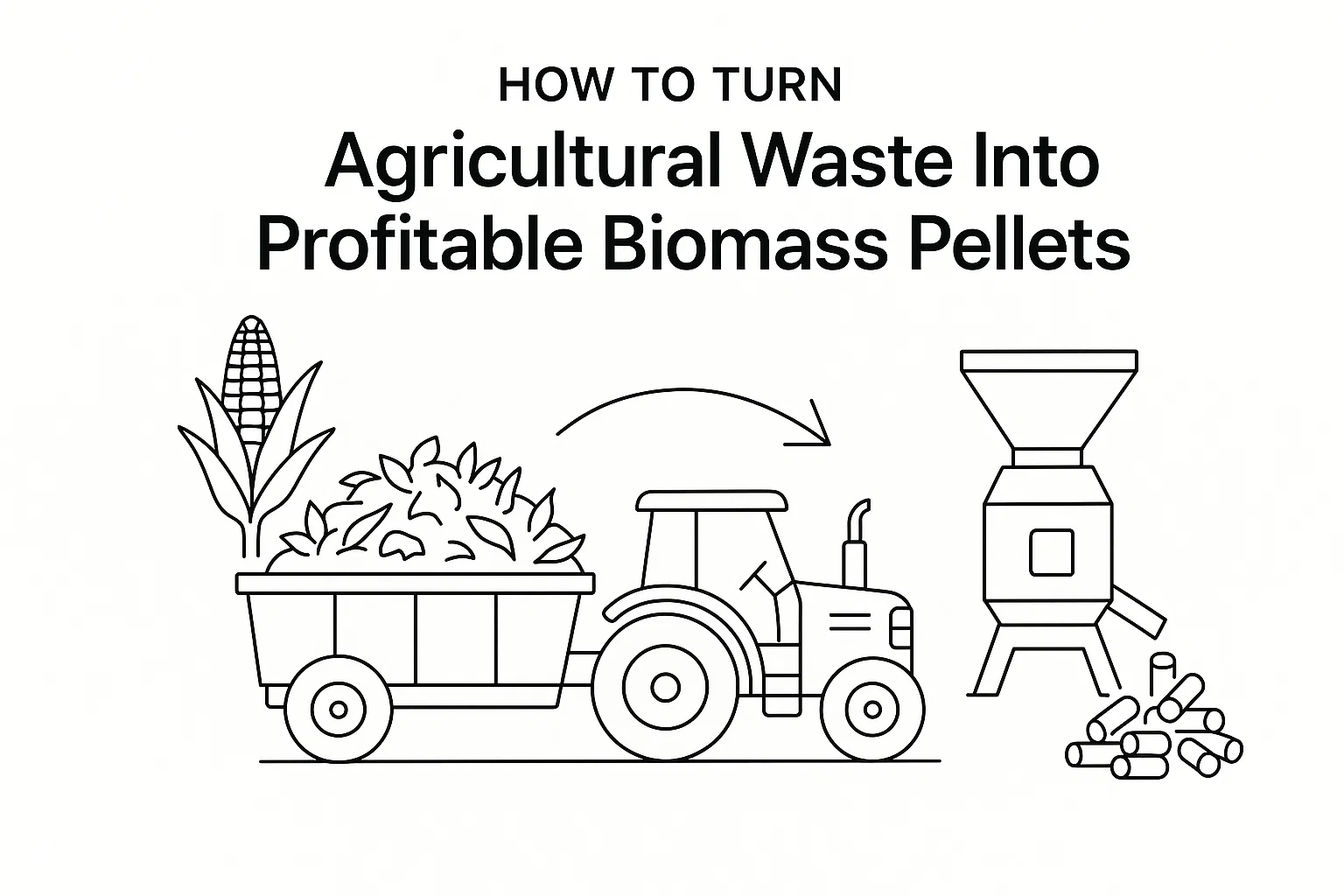

Farming not only yields crops, but also generates a significant amount of agricultural waste, including straw, husks, shells, and stalks. Traditionally, this waste has either been burned or discarded, causing pollution and offering no added value. However, with modern technology, agricultural waste can be converted into biomass pellets, creating a renewable energy source and opening new income streams for farmers and rural entrepreneurs.

In this guide, we’ll explore the benefits, processes, and machinery involved in agricultural waste pellet production. We’ll also demonstrate how this innovative approach can help farmers and agri-businesses turn waste into wealth.

What Are Agricultural Waste Pellets?

Agricultural waste pellets are compact, cylindrical units made from crop residues and plant byproducts. These biomass pellets serve as a biofuel for heating systems, power generation, and even animal bedding.

Common raw materials for pellet production include:

- Wheat or rice straw

- Corn stalks and cobs

- Peanut shells

- Cotton stalks

- Sugarcane bagasse

- Palm fiber or husk

These materials are typically abundant and underutilized, making them ideal for low-cost, sustainable pellet production.

Why Produce Pellets from Agricultural Waste?

1. Eco-Friendly Energy Source

Biomass pellets burn cleaner than traditional fuels such as coal or firewood, reducing carbon emissions and contributing to a sustainable energy cycle.

2. Cost-Effective Fuel Alternative

Pellets offer a consistent energy output, making them a reliable and affordable fuel source for household stoves, boilers, and industrial furnaces, all at a lower cost than conventional fuels.

3. Reduce Waste Disposal Issues

Converting agricultural waste into pellets helps reduce harmful burning and dumping, promoting better waste management practices and improving soil health.

4. Create Additional Revenue

Farmers can sell pellets to local households, green energy companies, or export markets. In many countries, governments offer incentives or subsidies for biomass fuel production, creating additional financial opportunities.

The Agricultural Waste Pellet Production Process

Here’s a step-by-step breakdown of how agricultural waste is transformed into valuable biomass pellets:

Step 1: Collect and Sort Raw Materials

Agricultural residues are gathered and sorted to remove contaminants such as stones, plastics, and metals.

Step 2: Crushing

The raw materials are crushed into a fine powder to ensure uniform quality when pelleted.

Step 3: Drying

Moisture content is reduced to 10-15%, the optimal range for pelletizing.

Step 4: Pelletizing

The dried material is then compressed into cylindrical pellets using a pellet machine, applying high pressure.

Step 5: Cooling and Packaging

Once formed, the pellets are cooled and packed into bags, ready for storage, sale, or transport.

Choosing the Right Pellet Machine

Selecting the appropriate pellet machine is critical for efficient biomass pellet production. Here are key factors to consider:

- Flat Die Pellet Mill: Ideal for small farms and startups, offering flexibility and ease of use.

- Ring Die Pellet Mill: Designed for commercial-scale production with higher throughput.

- Power Options: Choose between electric, diesel, or PTO-driven models, depending on your power availability.

- Capacity: Pellet mills range from 300 kg/h to several tons per hour, depending on the scale of production.

- Anti-Binder Design: Look for pellet mills equipped with anti-binder features for processing fibrous materials like straw or husks.

Market Opportunities for Agricultural Waste Pellets

As global demand for renewable energy rises, so too does the market for biomass energy. Several key industries and regions present lucrative opportunities for agricultural waste pellets:

- Rural heating in cold climates

- Biomass power plants looking for reliable fuel sources

- Animal bedding suppliers seeking eco-friendly options

- Organic fertilizer blends incorporating pellets for added value

- Export to Europe, South Korea, and Japan, where biomass fuel demand is growing rapidly

With the right setup, agricultural waste pellet production can be both eco-friendly and profitable.

Conclusion

Agricultural waste no longer needs to be seen as a burden; it can be transformed into a valuable resource. With minimal investment in pellet production equipment and a reliable supply of crop residues, farmers and agri-entrepreneurs can create sustainable energy solutions and generate new income from existing resources. Biomass pellet production not only helps reduce waste but also contributes to a greener, more circular economy.