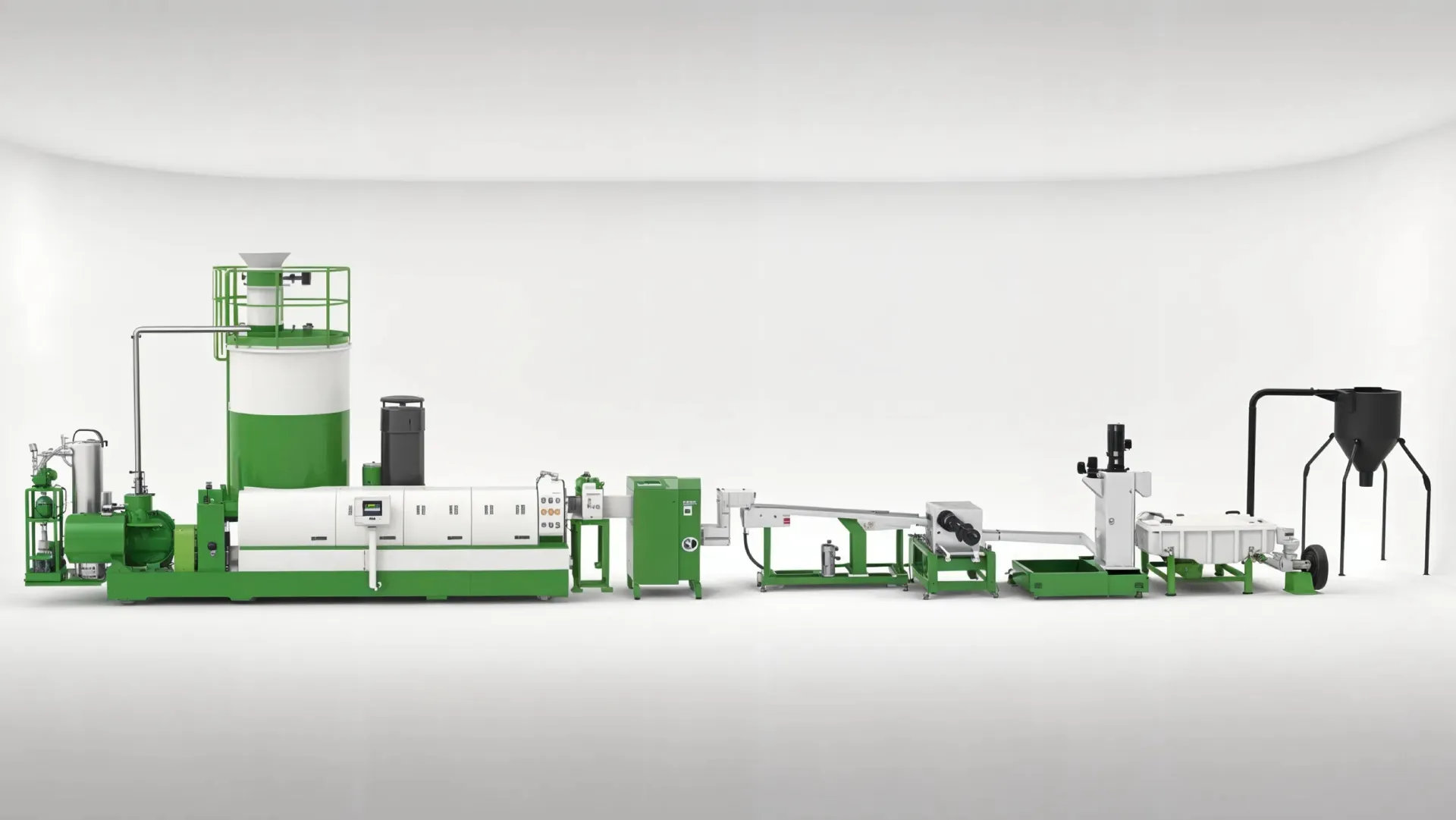

Machine de recyclage de tissus non tissés par fusion

Transformez les déchets de non-tissés soufflés par fusion de faible densité en granulés de PP à haute valeur ajoutée et à indice de fluidité élevé. Notre ligne spécialisée est conçue pour relever les défis uniques du recyclage des matériaux pelucheux provenant des masques, des filtres et des déchets de production.

Demande de proposition technique

Demande de proposition technique

Conçu pour les tissus non tissés

Les recycleurs standard échouent avec les matériaux pelucheux. Notre machine est spécialement conçue pour traiter les tissus soufflés par fusion et d'autres tissus non tissés.

Maîtriser l'alimentation à faible densité

Notre coupeur-compacteur intégré est la technologie de base qui permet de densifier les matériaux pelucheux, en résolvant les problèmes d'alimentation courants tels que les ponts et le colmatage, pour un processus stable et continu.

Préserver l'intégrité des matériaux (High MFI)

La vis d'extrusion spécialisée et le processus de fusion en douceur sont conçus pour minimiser la dégradation thermique et préserver l'indice de fluidité à chaud élevé du matériau PP d'origine.

Production uniforme de granulés

Le système de granulation de type "strand" (coupeur de nouilles) permet d'obtenir des granulés cylindriques de taille et de forme constantes, qui sont très appréciés pour leur réutilisation dans la fabrication.

Vitrine des technologies clés

Notre machine intègre des composants de pointe pour assurer un traitement efficace et stable des tissus soufflés par fusion.

Extrudeuse spécialisée

Une extrudeuse spécialisée à vis unique fait fondre en douceur le matériau précompacté. Les déchets plastiques sont bien fondus et plastifiés dans une section de traitement 36D.

- Dégazage sous vide à deux zones : Élimine efficacement les substances volatiles et l'humidité.

- Fusion douce : Préserve l'indice de fluidité élevé (MFI) du matériau PP d'origine.

- Optimisé pour une faible densité : Assure une pression stable et une plastification constante.

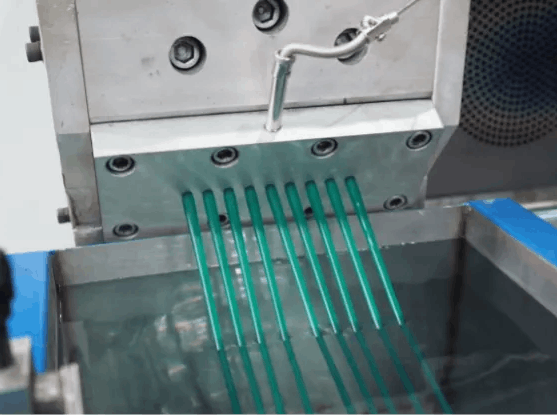

Coupeur de nouilles Système de coupe par brins

Ce système est idéal pour produire des granulés cylindriques uniformes. Le plastique fondu est extrudé en brins, qui sont ensuite refroidis et coupés à une longueur précise.

- Bac de refroidissement en acier inoxydable de 4 mètres : Fournit un refroidissement suffisant pour des granulés de haute qualité.

- Ajustable Design : L'évier peut être ajusté pour un refroidissement et une manipulation optimaux des brins.

- Entretien facile : Conçu pour faciliter les changements d'eau et le nettoyage.

Notre processus de recyclage en 4 étapes

Des déchets duveteux aux ressources précieuses, notre ligne automatisée simplifie l'ensemble du processus.

Alimentation et densification

La ferraille soufflée en fusion est densifiée dans le compacteur à couteaux pour une alimentation stable.

Extrusion et dégazage

Le matériau est fondu, plastifié et dégazé sous vide pour éliminer les impuretés.

Strand Cooling & Cutting

Le PP fondu est extrudé en brins, refroidi et découpé en granulés uniformes.

Séchage et collecte

Les granulés sont déshydratés et stockés, prêts à être réutilisés dans de nouvelles fabrications.

Paramètres techniques

| Modèle | ML85 | ML100 | ML130 | ML160 | ML180 |

|---|---|---|---|---|---|

| Production (kg/h) | 180~250 | 300~400 | 500~600 | 700~800 | 1000~1500 |

Questions fréquemment posées

Obtenir un devis personnalisé

Parlez-nous de vos déchets de fusion-soufflage et de vos objectifs de production. Nos ingénieurs vous proposeront une solution sur mesure et un devis compétitif.