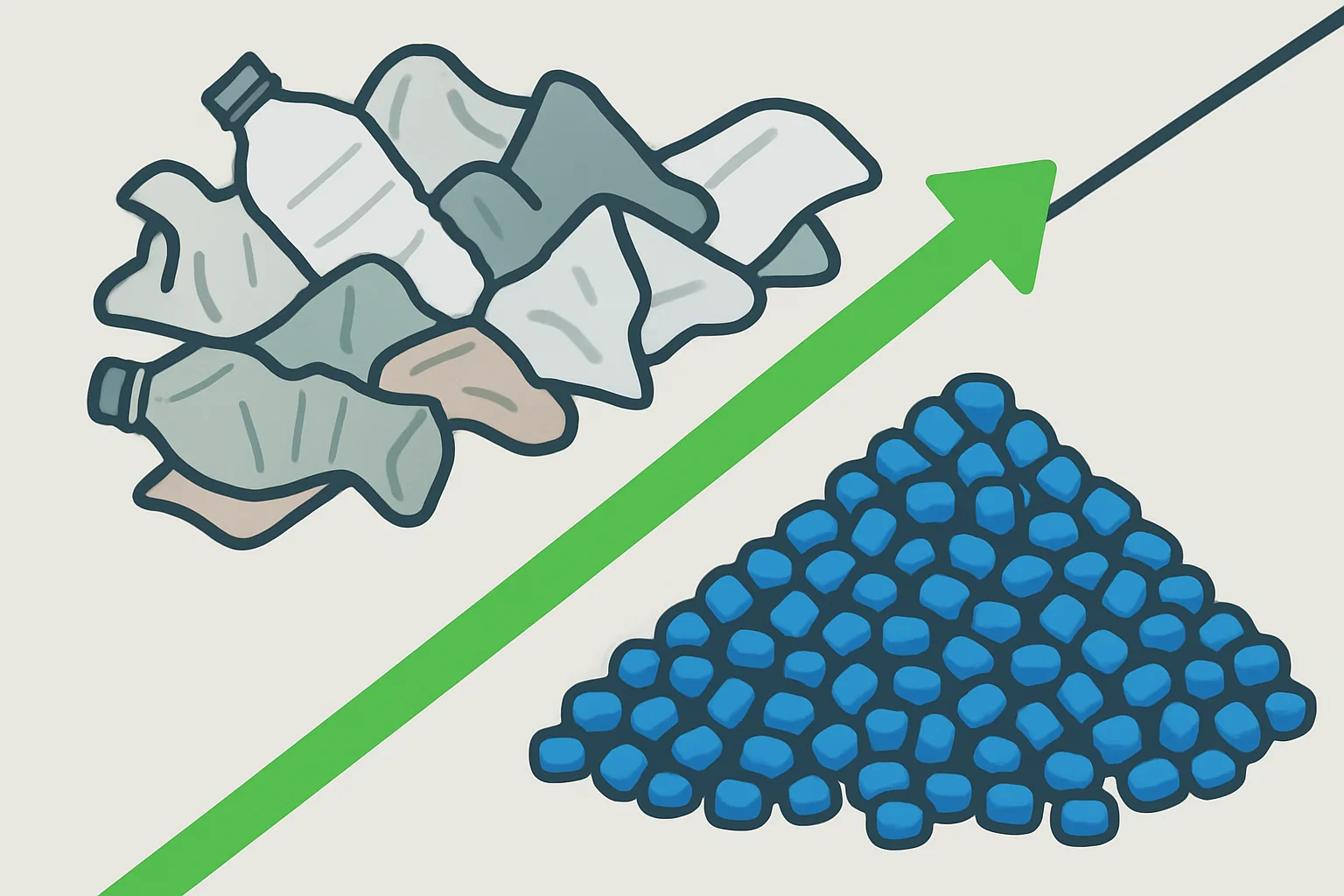

Plastic pelletizing is the critical final step in the plastic recycling process, transforming cleaned and shredded plastic waste into uniform, high-value pellets. If your business is grappling with how to handle plastic scrap, reduce operational costs, or improve production efficiency, understanding this process is not just beneficial—it’s essential. In a world facing unprecedented challenges from plastic pollution, recycling plastic into pellets stands as a powerful solution, turning a costly problem into a profitable opportunity and forming the backbone of a true circular economy.

This comprehensive guide will walk you through the entire plastic pelletizing process. We’ll explore the core principles, dive deep into the machinery at work, and uncover the significant advantages that make this technology a cornerstone of modern, sustainable manufacturing.

Part 1: The Core Definition – What Exactly is Plastic Pelletizing?

At its heart, plastic pelletizing is an industrial process that takes processed plastic waste—such as shredded film, crushed bottles (flakes), or industrial offcuts—and converts it through melting, filtering, and cutting into small, consistent granules or pellets.

Think of it like turning a pile of irregular wood scraps and sawdust into perfectly uniform, easy-to-use wood pellets for a stove. The raw plastic waste is often bulky, contaminated, and difficult to handle. The final pellets, however, are a standardized, clean, and flowable raw material, ready to be reintroduced into manufacturing cycles to create new products.

The Purpose: Why Turn Waste Plastic into Pellets?

Converting waste into pellets is not just about changing the shape of the material. It’s a value-added process designed to solve several fundamental problems in plastic recycling.

- Standardization for Manufacturing: Manufacturers need raw materials that are predictable. The injection molding, blow molding, and extrusion machines they use are highly precise instruments that require a consistent, free-flowing feedstock. Raw plastic scrap is anything but consistent. Plastic pelletizing creates uniform pellets of a specific size, shape, and density, ensuring they can be accurately dosed, conveyed, and melted in downstream production machinery without causing blockages or process variations. This standardization is the key to creating a reliable, high-quality recycled raw material.

- Purification and Property Enhancement (Compounding): The melting stage of the pelletizing process provides a unique opportunity to purify and enhance the plastic. As the plastic is melted in the extruder, it is forced through an extremely fine mesh filter screen (a screen changer) that removes residual contaminants like paper, wood fibers, or non-melting plastics. Furthermore, this is the ideal stage to introduce additives—a process known as compounding. Color masterbatch can be added to create pellets of a specific color, reinforcing agents like glass fiber can be mixed in to increase strength, and UV stabilizers can be added to improve weather resistance. This turns basic recycled material into a performance-tuned engineering plastic.

- Increased Bulk Density for Logistics: Loose plastic film, shredded scraps, and even bottle flakes have a very low bulk density. They take up a huge amount of space for their weight, making storage and transportation incredibly inefficient and expensive. The plastic pelletizing process densifies the material significantly. A truckload of uniform plastic pellets can contain many times more actual material by weight than a truckload of loose film, drastically cutting shipping costs per pound and saving valuable warehouse space.

- Creating a Marketable Commodity: In the recycling industry, standardized materials are valuable commodities. Unprocessed plastic waste has a very limited, often volatile market value. However, clean, uniform recycled plastic pellets are a globally traded commodity with a stable and much higher value. They have technical data sheets, defined properties, and are considered a direct substitute for virgin plastic resins by many manufacturers. Recycling plastic into pellets elevates the material from “waste” to a valuable industrial “product.”

Part 2: The In-Depth Process – How a Plastic Pelletizing Machine Works

A complete plastic pelletizing line is not a single machine but an integrated system of components working in concert. While configurations vary based on the type of plastic and its condition, the core process follows a logical, multi-stage progression.

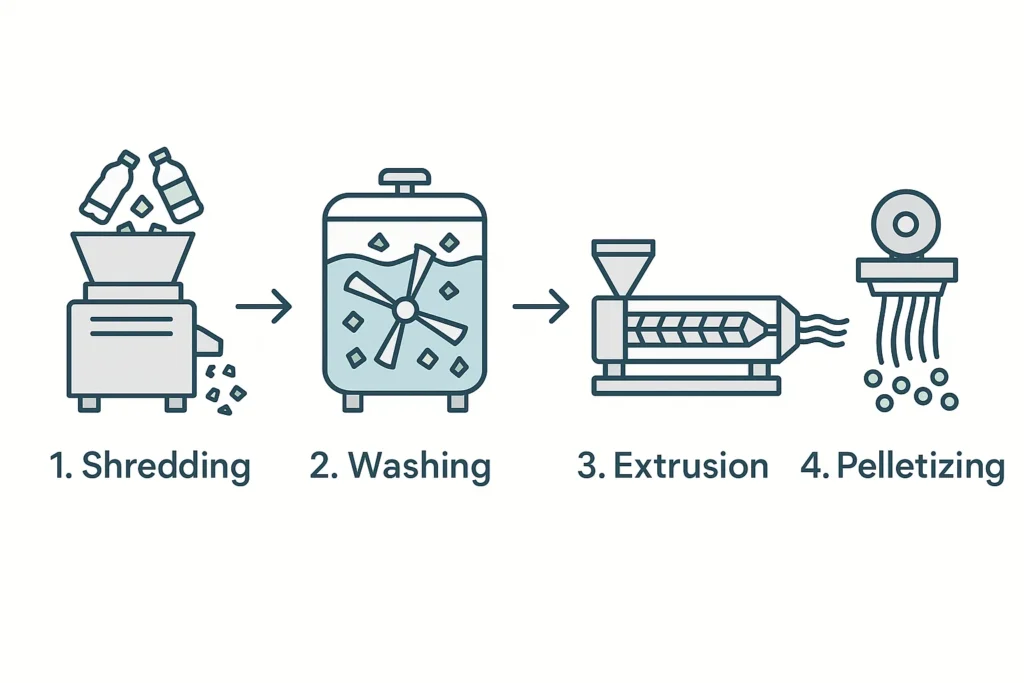

Stage 1: The Pre-Treatment Phase

Success in plastic pelletizing begins long before the plastic is ever melted. Proper pre-treatment is non-negotiable for producing high-quality pellets.

- Size Reduction (Shredding and Crushing): The raw plastic waste must first be reduced to a consistent, manageable size. This is where industrial shredders and granulators are essential.

- For bulky items like plastic drums, large purgings, or bundled films, a high-torque, low-speed shredder is used for primary size reduction.

- For materials like plastic pipes or rigid plastics, a specialized pipe shredder or heavy-duty granulator provides a more aggressive cutting action.

- The goal is to create small, uniform flakes or chips (typically under 12mm) that can be fed smoothly into the pelletizing extruder. For maximum efficiency, many operations use an integrated shredder and granulator machine that combines both steps.

- Washing and Drying: Most post-consumer and post-industrial plastic is contaminated with dirt, sand, oil, paper labels, and moisture. These contaminants must be removed. The shredded plastic enters a washing line, which can include:

- Float-Sink Tanks: Separates heavier plastics (like PET) from lighter ones (like PE/PP) and washes away heavy contaminants like sand and metal.

- Friction Washers: High-speed paddles scrub the plastic flakes against each other to remove stubborn dirt and labels.

- Hot Washing: Uses heated water and detergents to remove grease and glue.

- Séchage : After washing, the plastic must be thoroughly dried. Any residual moisture will turn into steam in the hot extruder, creating bubbles (voids) in the final pellets and degrading the plastic’s quality. This is achieved using centrifugal dryers and thermal drying systems.

Stage 2: The Melt Extrusion Phase

This is the heart of the machine à granuler le plastique, where the prepared plastic flakes are transformed into a homogenous molten polymer.

- Système d'alimentation : Clean, dry flakes are fed from a hopper into the extruder. For light, fluffy materials like film, a force-feeder or compactor may be used to densify the material and ensure a steady, consistent feed rate into the extruder screw.

- The Extruder: The extruder is a long, heated barrel containing a rotating screw (or two, in a twin-screw extruder). As the screw rotates, it conveys the plastic flakes forward. The combination of friction from the screw’s movement and heat from external heater bands melts the plastic. The screw’s design is highly engineered to compress, mix, and homogenize the molten plastic, ensuring a consistent temperature and viscosity.

- Venting/Degassing: High-quality extruders feature vented barrels. These are vacuum ports along the barrel that suck out any remaining moisture, air, and other volatile gases that are released as the plastic melts. This step is critical for preventing porosity in the final pellets and ensuring a smooth, high-quality surface finish on products made from them.

- Filtration des matières fondues : Before the molten plastic can be cut into pellets, it must pass through a final filtration stage. A screen changer holds a fine metal mesh that catches any last solid contaminants (metal, carbon char, etc.) that were not removed during washing. This protects the downstream equipment and guarantees the purity of the final product.

Stage 3: The Pelletizing and Cooling Phase

Once the plastic is a clean, homogenous melt, it’s ready to be cut into pellets. There are three primary methods for this, each with its own advantages.

- 1. Strand Pelletizing (Cold-Cut System): This is the most common and straightforward method.

- Processus : The molten plastic is extruded through a die with multiple small, round holes, forming continuous strands resembling spaghetti. These strands are immediately submerged in a long water trough or bath to cool and solidify. At the end of the trough, the hardened strands are pulled into a pelletizer, which uses a set of rotating blades to chop them into short, cylindrical pellets.

- Best for: A wide range of polymers, especially good for testing and small-batch production due to its simplicity.

- 2. Water-Ring Pelletizing (Hot-Die Face Cut System): This is a more automated and compact system.

- Processus : The plastic is extruded through the die directly into the path of a rotating cutting head. As the plastic emerges, blades instantly slice it into pellets right at the die face. A ring of circulating water immediately catches the hot pellets, cooling them and transporting them in a slurry to a centrifugal dryer, which separates the pellets from the water.

- Best for: High-volume production of polyolefins like PE and PP. It produces more uniform, lens-shaped pellets than strand pelletizing.

- 3. Underwater Pelletizing (UWP): This is the most advanced and sophisticated system.

- Processus : Similar to water-ring cutting, the pellets are cut at the hot die face. However, the entire cutting chamber is flooded with temperature-controlled water. The pellets are cut, cooled, and solidified in a single, enclosed environment before being piped to a dryer.

- Best for: A wide range of plastics, including temperature-sensitive materials like nylons and sticky polymers. It produces perfectly spherical pellets of the highest quality and uniformity.

After cutting and cooling, the finished pellets are air-conveyed to a storage silo, where they are often passed through a classifier to remove any oversized or undersized pieces before being bagged for shipment.

Part 3: The Business Value – 4 Core Advantages of Plastic Pelletizing

Investing in a waste plastic recycling and pelletizing system delivers tangible returns that go far beyond simple waste management.

- 1. Dramatically Increased Material Value: This is the most direct financial benefit. You are taking a low-value (or even negative-value) waste stream and transforming it into a high-value, in-demand industrial commodity. Clean, consistent recycled pellets can often sell for 60-80% of the price of their virgin counterparts, creating a significant new revenue stream.

- 2. Enhanced Downstream Manufacturing Efficiency: For companies that generate and reuse their own industrial scrap (a “closed-loop” system), using re-pelletized material instead of raw regrind offers huge advantages. The uniform pellets feed smoothly into production machinery, leading to more stable processes, less downtime from material blockages, and a higher-quality final product. This direct improvement in OEE (Overall Equipment Effectiveness) translates to lower production costs and higher profits.

- 3. Improved Health, Safety, and Environment (HSE): Handling loose, dusty plastic regrind can create significant airborne dust, which can be a respiratory hazard and, in some cases, a combustible dust explosion risk. Converting this material into clean, dust-free pellets makes the workplace safer and cleaner. Furthermore, the densified material is easier to handle with standard conveying equipment, reducing manual labor and the risk of injuries.

- 4. Driving a True Circular Economy: Plastic pelletizing is the enabling technology for the circular economy. Without it, most plastic waste cannot be effectively reused in high-value applications. By creating a reliable supply of high-quality recycled raw materials, pelletizing reduces our dependence on fossil fuels to produce virgin plastics, lowers the carbon footprint of manufacturing, and provides a real, scalable solution to keep plastic out of landfills and oceans. For modern businesses, this is a powerful story to tell customers and stakeholders, enhancing brand reputation and aligning with corporate sustainability goals.

Part 4: Applications – The New Life of Recycled Plastic Pellets

Once the waste plastic recycling process is complete, the resulting pellets become the building blocks for a vast array of new products.

- Injection Molding: Recycled pellets (especially PP, HDPE, and ABS) are widely used to injection mold durable goods like shipping pallets, crates, trash bins, automotive components (bumpers, dashboards), buckets, and outdoor furniture.

- Blow Molding: Recycled HDPE pellets are commonly used to blow mold non-food containers like bottles for detergents, motor oil, and shampoo, as well as large items like industrial drums and drainage pipes.

- Extrusion: Recycled pellets are extruded into a variety of profiles and sheets. This includes applications like composite lumber for decking and fencing, drainage pipes, electrical conduit, and plastic sheeting for construction and agriculture.

- Film Blowing: Recycled LDPE and LLDPE pellets are blown into new films used for trash bags, construction sheeting, and agricultural films.

- Fiber and Textiles: Recycled PET pellets (from bottles) are the primary feedstock for producing polyester staple fiber. This fiber is used to make clothing (fleece jackets), carpets, and stuffing for pillows and sleeping bags.

Conclusion: Your First Step Towards Profitable Recycling

Plastic pelletizing is more than just a recycling process; it is a strategic business transformation. It is the definitive method for converting a problematic waste stream into a valuable, consistent, and profitable raw material. From the initial size reduction with robust shredders and granulators to the final production of high-quality pellets, each step is an opportunity to add value and improve your operational and environmental bottom line.

A successful plastic pelletizing operation hinges on reliable, high-performance machinery. Having the right pre-treatment equipment, like a powerful shredder matched to your specific waste stream, is the foundation for a smooth and efficient process.

Ready to explore how a complete solution—from shredding to pelletizing—can transform your plastic waste? Contact Rumtoo Machine today to speak with our experts and design a system tailored to your specific needs.