In de concurrerende kunststofrecyclingsindustrie bepaalt de kwaliteit van je uiteindelijke pellets je marktwaarde. Maar zelfs de meest robuuste Hulpbronnenbesparing: kunnen operationele hindernissen tegenkomen die de consistentie van de uitvoer beïnvloeden. Weten hoe je deze problemen snel oplost, is het verschil tussen een winstgevende shift en kostbare stilstand.

Als toonaangevende specialist in hoogwaardige extrusie, Rumtoo biedt deze uitgebreide gids om operators te helpen bij het identificeren, oplossen en voorkomen van de 7 meest voorkomende problemen bij het pelletiseren.

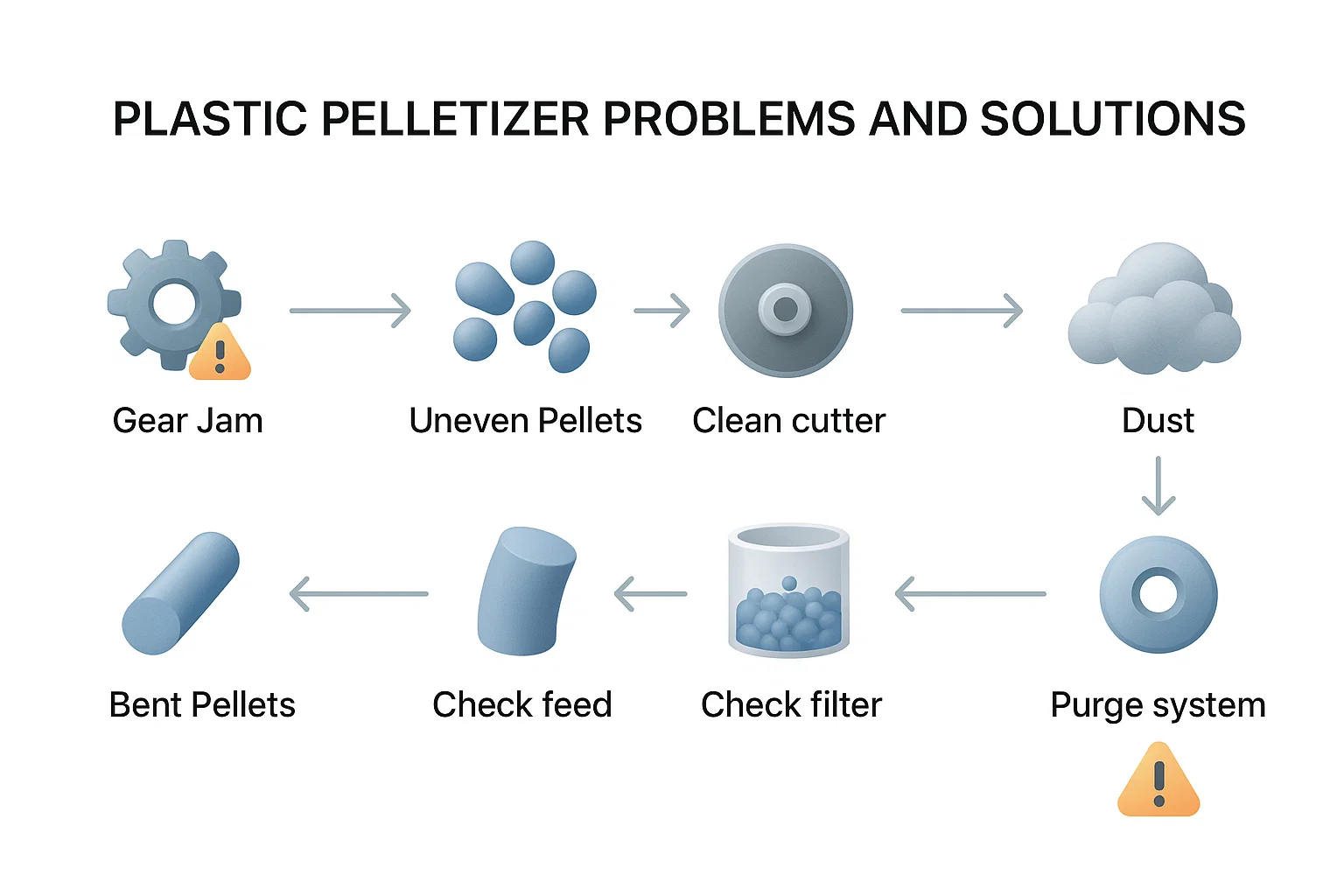

Veelvoorkomende uitdagingen bij het pelletiseren & oplossingen van experts

1. Onzekerheid bij het Voeden van het Materiaal

Het probleem: Onregelmatige materiaalstroom in de extruder, wat leidt tot schommelingen en ongelijkmatige pelletdichtheid.

Rumtoo Inzicht: Dit komt vaak voor bij het verwerken van een mix van volumineuze harde kunststoffen en lichte folies. Inconsistente vlokken van shredders van lage kwaliteit veroorzaken “brugvorming” in de trechter.

- Controleer op vreemde metalen deeltjes in de toevoerpoort.

- Verhoog het voervolume of gebruik een systeem met geforceerde toevoer.

- Zorg voor gelijkmatig versnipperen met een Rumtoo éénassige versnipperaar.

2. Niet-uniforme korreluitvoer

Het probleem: Verschijnen van “staarten”, “tweelingen” of gevarieerde pelletlengtes.

De oplossing: Precisie is essentieel. Niet-uniformiteit is meestal het gevolg van een mismatch tussen de smeltsnelheid en de snijsnelheid.

- Kalibreer de speling tussen mes en matrijs om gaten te voorkomen.

- Upgrade naar een automatisch snelheidsreagerend snijsysteem.

- Vervang versleten messen regelmatig om een schone schaar te behouden.

Technische problemen oplossen: Diep duik

3. Agglomeratie en Pellet Clustering

Pellets die aan elkaar kleven (clusteren) vlak na de voorkant van de matrijs is een klassieke fout in het thermisch beheer. Als het koelmedium de warmte niet snel genoeg afvoert, blijft het polymeer kleverig.

Waarom het gebeurt:

- De temperatuur van het spoelwater is te hoog.

- Onvoldoende waterstroom in de koeltrog.

- De matrijsgaten zijn te dicht bij elkaar geplaatst voor het specifieke polymeer.

De Rumtoo-oplossing:

- Verlaag de temperatuur van het waterbad en verhoog de stroomsnelheid.

- Optimaliseer de concentratie van de oppervlakteactieve stof om de oppervlaktespanning te verlagen.

- Zorg ervoor dat de koeling van het matrijsoppervlak gesynchroniseerd is met de extrusiesnelheid.

4. Fijne deeltjes, stof en engelenhaar“

De aanwezigheid van plastic stof (fijnstof) of dunne slierten (engelenhaar) duidt op mechanische wrijving of brosse breuk tijdens het drogen of snijden.

Om dit op te lossen, moet je de uitlijning van de messenas controleren. Als je een centrifugaaldroger gebruikt, kan het verlagen van het toerental de impactkracht op broze pellets verminderen, waardoor de stofophoping aanzienlijk vermindert.

5. Vervormde pellets (Longs & Elbows)

Lange pellets ontstaan wanneer de snijplotter te traag is; “ellebogen” of gebogen pellets ontstaan wanneer het materiaal wordt gesneden terwijl de kern nog te heet is of wanneer de matrijstemperatuur ongelijk is.

Tip: Breng je thermische profiel in balans. De matrijstemperatuur verhogen en tegelijkertijd de mesrotatiesnelheid verhogen levert meestal de meest symmetrische resultaten op.

6. Interne holtes en “popcorn”-defecten

Leemtes of bellen in de pellet (vaak het “popcorneffect” genoemd) worden bijna altijd veroorzaakt door ingesloten vocht of vluchtige stoffen.

- Voordrogen: Zorg ervoor dat polymeren goed gedroogd zijn voordat ze de extruder ingaan.

- Afvoeren: Controleer of het vacuümontgassingssysteem op uw Kunststof Pelletiseerlijn op zijn efficiëntst werkt om gassen te verwijderen.

- Koeling: Verhoog de temperatuur van het bluswater iets om het “bevriezen” van het oppervlak te vertragen, zodat de interne gassen kunnen ontsnappen.

7. Motoroverbelasting en storingen in de aandrijving

Mechanische belasting is vaak het gevolg van “koude starts” of het verwerken van materiaal dat niet goed is voorbewerkt. De geïntegreerde systemen van Rumtoo, zoals onze Zware HDPE Plastic Pijpversnipperaars, Zorg ervoor dat het materiaal dat de pelletiseermachine binnenkomt al geoptimaliseerd is voor het ontwerp van de schroef.

Rumtoo Koopgids: Machine levensduur maximaliseren

Betrouwbaarheid is geen toeval, maar een kwestie van techniek. Om de 7 bovenstaande problemen te minimaliseren, raden we een “System-First” benadering van recycling aan:

- Geautomatiseerde synchronisatie: Kies machines waarbij de feeder, extruder en cutter in real-time communiceren.

- Robuuste voorbewerking: Gebruik speciale shredders voor harde kunststoffen vs. zachte folies om een consistente bulkdichtheid te garanderen.

- Preventief onderhoud: Regelmatige controles van de verwarmingsband voorkomen “ongesmolten” segmenten die de motor belasten.

Ontdek hoogwaardige recyclingsystemen

Conclusie: De professionele keuze

Operationele uitmuntendheid in kunststofrecycling vereist zowel deskundige kennis als superieure machines. Door de hoofdoorzaken van toevoer, thermische controle en mechanische uitlijning aan te pakken, kunt u uw afvalstroom omzetten in een hoogwaardig product.

Rumtoo ontwerpt elke Geïntegreerde versnipperaar en granuleermachine met deze stappen voor probleemoplossing in gedachten - oplossingen inbouwen zodat u ze later niet hoeft te vinden. Ervaar vandaag nog de stabiliteit van recyclingtechnologie van professionele kwaliteit.