In the dynamic world of plastic recycling, the efficiency and quality of your output hinge on the machinery you employ. At the heart of the recycling line lies the plastic pelletizer, a critical component that transforms molten plastic into uniform, marketable pellets. However, not all pelletizers are created equal. The choice of a pelletizing system can significantly impact your operational efficiency, pellet quality, and overall profitability.

For industrial recycling professionals, selecting the right equipment is a decision that requires careful consideration of material types, production volumes, and operational costs. Two of the most prevalent systems in the industry are the wind-cooled (or air-cooled) pelletizer and the water ring pelletizer.

This comprehensive guide, brought to you by the experts at Rumtoo, will delve into a detailed comparative analysis of these two technologies. We will explore their working principles, weigh their respective advantages and disadvantages, and provide clear guidance to help you make an informed decision for your facility.

The Wind-Cooled Plastic Pelletizer: Simplicity and Efficiency

A wind-cooled plastic pelletizer, often referred to as an air-cooled or dry-face pelletizer, is renowned for its straightforward design and operational simplicity. This system is particularly effective for processing rigid plastics with a low Melt Flow Index (MFI).

How It Works:

The process begins as the molten polymer is extruded through a die head. A set of rotating blades cuts the polymer strands at the die face. The freshly cut, hot pellets are then immediately discharged onto a cooling conveyor. A current of ambient or chilled air is forced over the pellets as they travel along this conveyor, gradually reducing their temperature until they are solid and can be collected in a hopper or silo.

[Diagram: A simplified flowchart illustrating the process of a Wind-Cooled Plastic Pelletizer, showing the extruder, die face, cutting blades, and a long air-cooling conveyor with fans blowing air upwards onto the pellets.]

Advantages:

- Cost-Effective: The simpler design, lack of water circulation systems, and fewer components result in a lower initial investment (CAPEX) and reduced maintenance complexity.

- Ideal for Water-Sensitive Polymers: This system is the go-to choice for hygroscopic or water-sensitive plastics like PET, as it entirely eliminates contact with water, preventing material degradation.

- Low Operational Complexity: The straightforward mechanics of the wind-cooled system make it easy to operate and troubleshoot, requiring less extensive operator training.

- Energy Efficient: By avoiding the need for water pumps and dryers, the overall energy consumption can be lower compared to water-based systems.

Disadvantages:

- Limited Material Range: Wind-cooled systems are less effective for high MFI (soft) plastics. The low viscosity of these materials can cause the pellets to deform or agglomerate before they have sufficiently cooled.

- Potential for Dust: The air-cooling process can sometimes generate fine plastic dust, which may require additional dust collection systems to maintain a clean and safe working environment.

- Less Uniform Pellets: The cooling process is less instantaneous than with water systems, which can sometimes result in slightly less uniform or spherical pellet shapes.

The Water Ring Plastic Pelletizer: Precision and Versatility

The water ring plastic pelletizer is a more advanced system designed for high performance and versatility. It is exceptionally well-suited for processing a wide array of thermoplastics, especially those with a higher MFI.

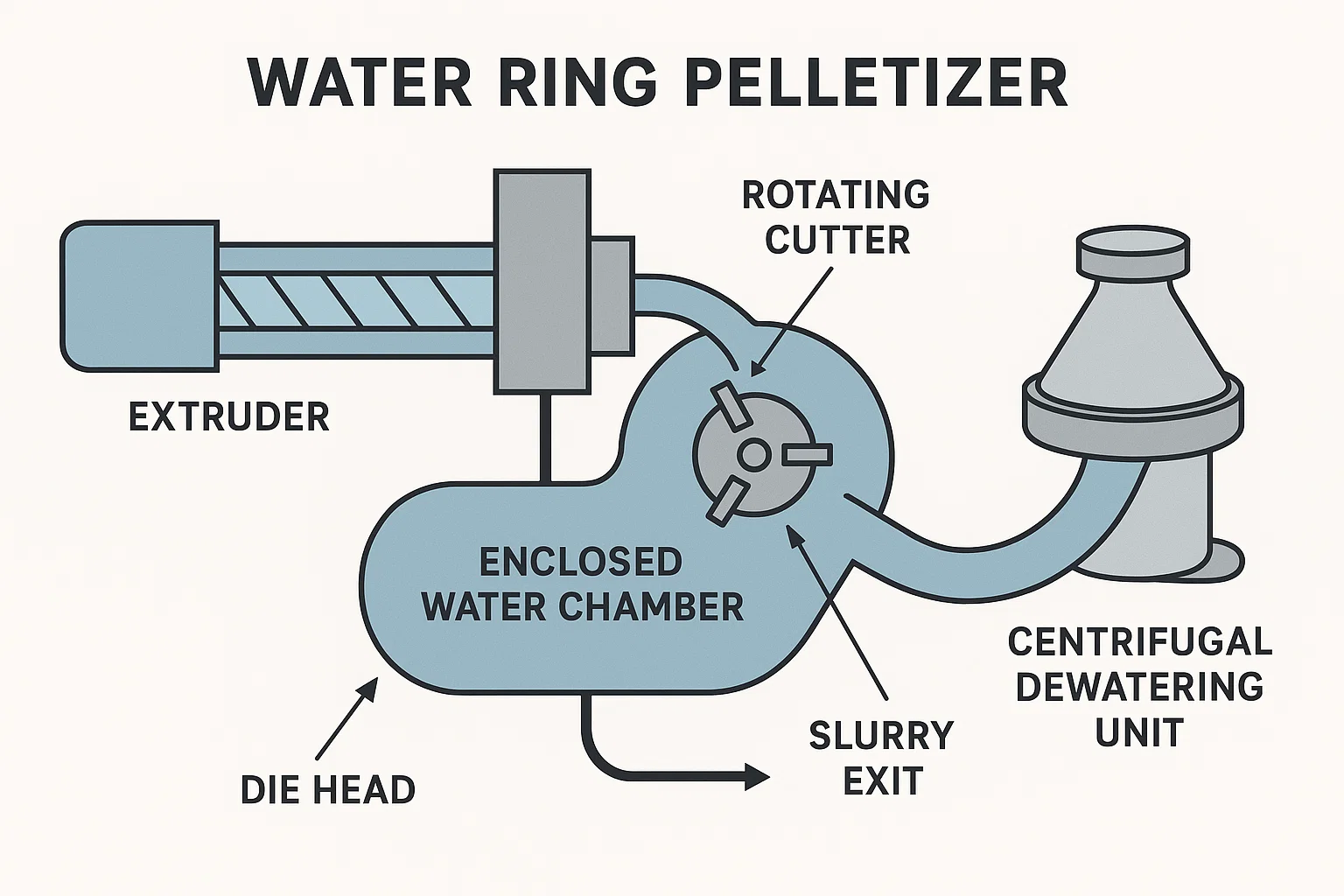

How It Works:

In a water ring system, the molten polymer is also extruded through a die face. However, the cutting blades rotate in an enclosed chamber, cutting the pellets directly into a circulating ring of temperature-controlled water. This water immediately quenches the pellets and transports them as a slurry to a dewatering unit. Here, the water is separated and recirculated, while the cool, dry pellets are discharged for collection.

Advantages:

- Superior Pellet Quality: The immediate and intense cooling provided by the water results in highly uniform, spherical pellets with a smooth, glossy finish, which is often preferred by end-users.

- Wide Material Compatibility: This system excels with a broad range of polymers, including soft, flexible plastics like LDPE, LLDPE, and PP, which are challenging for wind-cooled systems.

- High Throughput and Automation: Water ring pelletizers are designed for continuous, highly automated operation, making them ideal for high-volume recycling facilities.

- Dust-Free Operation: As the entire process is contained and utilises water, the generation of airborne dust is virtually eliminated, leading to a cleaner workspace.

Disadvantages:

- Higher Initial Investment: The complexity of the system, including the water circulation pumps, tempering system, and centrifugal dryer, leads to a higher upfront cost.

- Increased Operational Complexity: The system requires more precise control over water temperature and flow rates, demanding more sophisticated operational oversight.

- Higher Energy Consumption: The operation of water pumps and the large centrifugal dryer contributes to higher overall energy usage compared to wind-cooled alternatives.

- Not Suitable for Water-Sensitive Plastics: Direct contact with water makes this system unsuitable for highly hygroscopic polymers without an effective drying stage.

Head-to-Head Comparison: Wind-Cooled vs. Water Ring

To help you visualise the best fit for your operations, here is a direct comparison of the key performance indicators for each type of plastic pelletizer.

| Feature | Wind-Cooled Pelletizer | Water Ring Pelletizer |

| korrelmassa | Good, but can be less uniform. | Excellent, highly uniform, and spherical. |

| Material Suitability | Best for rigid, low-MFI plastics (e.g., HDPE, some PP). Ideal for water-sensitive polymers (e.g., PET). | Excellent for a wide range, especially high-MFI, soft plastics (e.g., LDPE, LLDPE, TPU). |

| Operational Complexity | Low. Simple mechanics and easy to maintain. | Moderate to High. Requires precise control of water systems. |

| System Footprint | Generally requires a longer footprint due to the cooling conveyor. | More compact cutting unit but requires additional space for the dewatering system. |

| Onderhoud | Lower. Fewer moving parts and no water system to manage. | Higher. Regular maintenance of the water pump, filtration system, and dryer is necessary. |

| Upfront Cost (CAPEX) | Lower. | Higher. |

| Operating Cost (OPEX) | Lower energy consumption. | Higher energy consumption due to pumps and dryer. |

Maak de juiste keuze voor uw operatie

Kies luchtgekoeld of watergekoeld plastic pelletizer Niet over welke algemeen "beter" is, maar welke het beste past bij uw specifieke behoeften.

- Kies een luchtgekoelde pelleteermachine als: Uw primaire grondstof bestaat uit harde, mfi-arme kunststoffen. U werkt met watergevoelige materialen of u beschikt over een beperkt startkapitaal en een beperkt budget voor technische opleidingen.

- Kies de hydrocyclische granulator als: U moet uw klanten de hoogste kwaliteit, de meest uniforme korrels. Uw ingredienten zijn divers, inclusief zachte, mfi kunststof. U beschikt over een grote capaciteit, waarbij automatisering en stofbestrijding de belangrijkste prioriteiten zijn. Voor bedrijven die zich richten op zachte kunststoffen, krachtige systemen zoals wij Enkele schroef granulator van zachte kunststof Vaak naadloos geintegreerd met geavanceerde water ring granulatie technologie.

Conclusie: partner voor uitstekende granulatie

Kennis van de nuances tussen luchtgekoelde en waterringvormige granulatoren is de eerste stap in het optimaliseren van de productielijn voor plastic recycling. Beide systemen hebben verschillende voordelen en de juiste keuze wordt afgestemd op uw materialenexpertise, productiedoelstellingen en financiele kaders.

Bij Rumtoo zijn we niet alleen trots op het leveren van machines, maar ook op het leveren van oplossingen. Ons team van technische experts staat klaar om u te helpen uw unieke behoeften te analyseren en u te adviseren plastic pelletizer Dit biedt maximale waarde en prestaties voor uw bedrijf.

Neem direct contact op met het Rumtoo team voor deskundig advies voor uw recyclingbedrijf.

Een reactie achterlaten