Introduction: Driving the Future of Automotive Recycling

The automotive industry is undergoing a monumental shift towards sustainability, driven by regulatory pressures and a growing consumer demand for eco-friendly vehicles. As cars become more advanced, the volume and complexity of the plastics they contain also increase, with the average vehicle today incorporating roughly 200kg of plastics and composites. This presents a significant challenge at the end of a vehicle’s life. How can we efficiently recover and reuse these valuable polymers to support a circular economy?

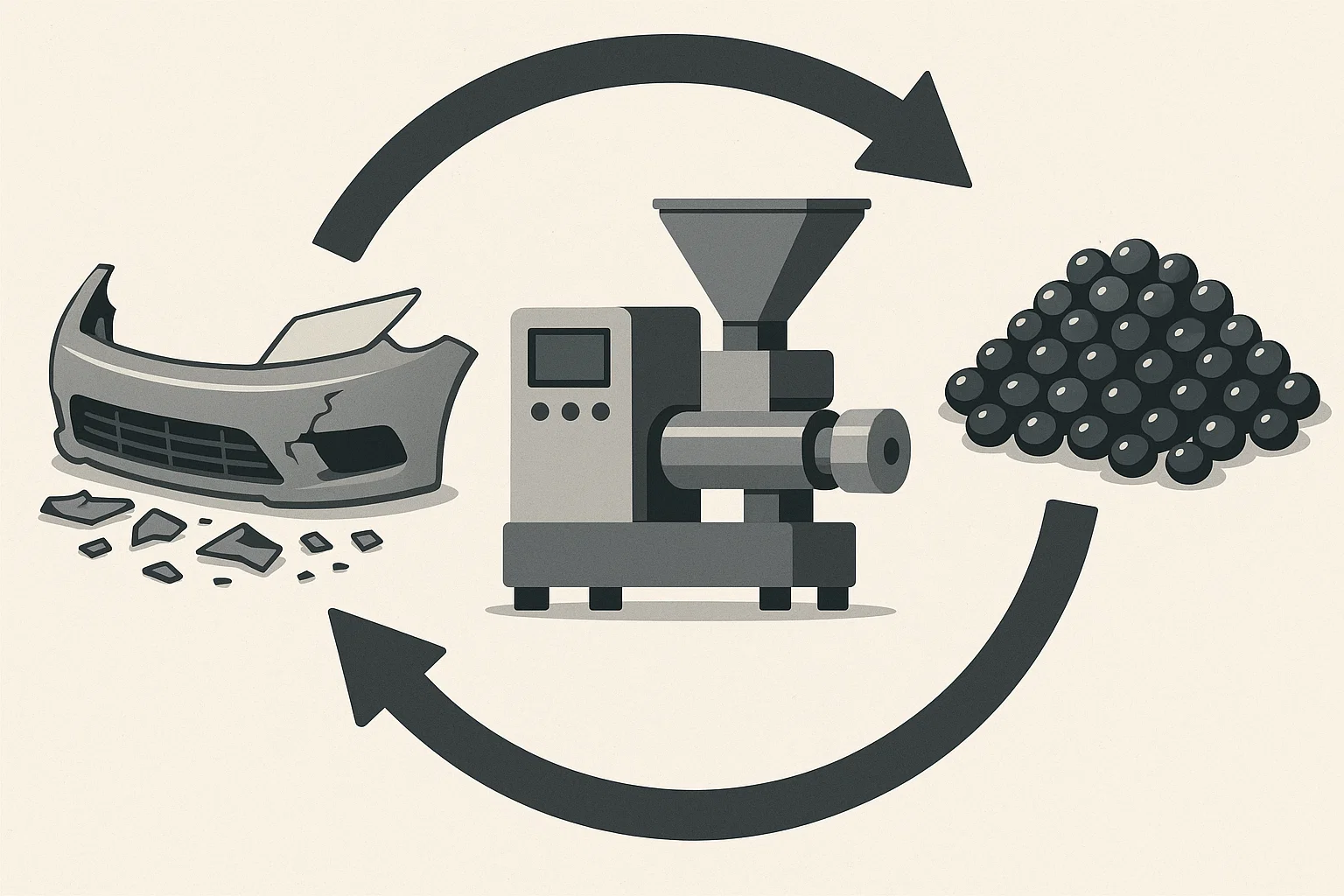

The answer lies in advanced recycling technologies, with pelletizing systems at the forefront of this transformation. These sophisticated machines are pivotal in converting heterogeneous plastic waste from end-of-life vehicles (ELVs) into uniform, high-quality pellets that can be reintroduced into the manufacturing stream. This article delves into the innovative applications of pelletizing systems in automotive plastics recycling, exploring how they tackle the industry’s unique challenges and pave the way for a more sustainable future. At Rumtoo Machine, we are dedicated to engineering cutting-edge pelletizing solutions that empower manufacturers and recyclers to turn automotive scrap into a valuable resource.

The Challenge: The Complex World of Automotive Plastic Waste

Recycling plastics from ELVs is notoriously complex. Unlike single-stream consumer plastics, automotive components are a heterogeneous mix of polymers, fillers, and contaminants. A typical vehicle contains around 39 different types of plastics, including polypropylene (PP), polyurethane (PU), polyamides (PA), and PVC, often compounded with materials like glass fibre or talc.

This mixture, often referred to as Automotive Shredder Residue (ASR) or “auto fluff,” makes up about 25% of a vehicle’s weight after metals are recovered. ASR is a challenging waste stream, consisting of plastics, rubber, glass, textiles, and residual fluids. The key challenges for recyclers include:

- Verontreiniging: Residues from fluids, paints, and adhesives can compromise the quality of the recycled plastic.

- Material Complexity: The wide variety of polymers, often bonded together, makes separation difficult and costly.

- Degradation: Automotive plastics are designed for durability, but after 15-20 years of service, their properties can be degraded, affecting recyclability.

- Economic Viability: The high cost of sorting and processing has historically made it difficult for recycled automotive plastics to compete with virgin materials.

Overcoming these hurdles requires technology that is not just powerful, but also intelligent and adaptable. This is where modern pelletizing systems demonstrate their true value.

The Recycling Workflow: From Car Bumper to Plastic Pellet

The journey from a discarded car part to a high-performance pellet involves several critical stages. Advanced pelletizing systems are an integral part of this process, ensuring the final output meets stringent quality standards.

Suggested Diagram: Automotive Plastics Recycling Workflow

- [Start] Dismantling & Shredding: ELVs are dismantled, and plastic-rich components are separated. The vehicle is then shredded to recover metals. The remaining ASR proceeds to the next stage.

- [Step 2] Sorting & Separation: Advanced sorting technologies (e.g., magnetic separation, air separation, polymer sorting) are used to isolate different types of plastics from the ASR.

- [Step 3] Washing & Drying: The sorted plastic flakes are thoroughly washed to remove contaminants and then dried to ensure a consistent moisture level, which is crucial for quality extrusion.

- [Step 4] Extrusion & Filtration: The clean flakes are fed into an extruder. A rotating screw melts and homogenises the plastic. High-performance filtration systems are critical here to remove any remaining impurities.

- [Step 5] Pelletizing: The molten, filtered plastic is forced through a die and cut into uniform pellets. This is the core function of the pelletizing system.

- [Step 6] Cooling & Drying: The newly formed pellets are immediately cooled (often using water or air) to solidify them and then dried.

- [End] Quality Control & Bagging: The final pellets are tested for quality and consistency before being packaged for use in new automotive components.

The Heart of the Process: Innovations in Pelletizing Systems

The pelletizer is more than just a machine for creating pellets; it is a sophisticated system that purifies, homogenises, and standardises recycled plastic, making it a viable alternative to virgin resin. Innovations in this field, championed by companies like Rumtoo Machine, are directly addressing the challenges of automotive plastics.

1. Advanced Feeding Systems:

The irregular shape and varying density of shredded automotive plastic require specialised feeding mechanisms. Modern systems, such as a cutter compactor feeder, can pre-heat, cut, and compact the material in a single step. This ensures a stable and continuous feed into the extruder, which is vital for consistent melt quality and higher output.

2. High-Efficiency Degassing and Filtration:

Automotive plastics can release volatile compounds and contain fine impurities. Rumtoo Machine pelletizing systems incorporate double-zone vacuum degassing systems to effectively remove moisture and volatiles. This is paired with multi-stage melt filtration technology that can screen out contaminants without interrupting production, ensuring the purity of the final pellets.

3. Specialised Screw and Barrel Designs:

The diverse mix of polymers and fillers in automotive scrap requires robust and adaptable extrusion. The screw and barrel, the core components of the extruder, are engineered for superior mixing, melting, and homogenisation. Custom screw geometries ensure that materials like glass-fibre-filled PP are processed without excessive degradation, preserving the mechanical properties of the recycled plastic.

4. Intelligent Cutting Technologies:

The cutting method determines the final quality and uniformity of the pellets. The two primary innovations are:

- Waterringgranulering: Ideal for materials like PP and PE, this method features blades cutting the molten plastic at the die face, with a ring of water immediately cooling and transporting the pellets. This produces uniform, high-quality pellets with minimal operator intervention.

- Pelletiseren onder water: This advanced technique cuts the polymer directly in a stream of water, creating perfectly spherical pellets with a smooth, dust-free surface. This is particularly effective for high-value engineering plastics found in automotive applications.

Suggested Chart: Performance Comparison of Pelletizing Systems

| Kenmerk | Strengkorrelvorming | [44] Waterringgranuleren | Onderwaterkorrelvorming |

|---|---|---|---|

| Kwaliteit van Pellets | Good (cylindrical) | Excellent (uniform, lentil-shaped) | Superior (spherical, dust-free) |

| Automation Level | Gemiddeld | Hoog | Zeer hoog |

| Materiaaltoepassing | Wide range | Polyolefins (PP, PE) | Wide range, incl. sensitive polymers |

| Operationele Kosten | Laag | Gemiddeld | Hoog |

| Voetafdruk | Groot | Compact | Compact |

| Ideal Application | General recycling | High-volume polyolefin recycling | High-purity engineering plastics |

The Result: High-Performance Pellets for a Circular Economy

The ultimate goal of this advanced recycling process is to produce recycled plastic pellets with properties comparable to virgin materials. High-quality recycled pellets offer manufacturers significant benefits:

- Kostenbesparingen: Recycled pellets are often more cost-effective than virgin resins, reducing raw material expenses.

- Environmental Compliance: Using recycled content helps automotive manufacturers meet increasingly stringent regulations in the USA and Europe regarding vehicle recycling and recycled content mandates.

- Sustainability Credentials: Incorporating recycled plastics enhances a brand’s reputation and appeals to environmentally conscious consumers.

- Resource Efficiency: It reduces reliance on fossil fuels, lowers energy consumption by up to 80% compared to virgin plastic production, and diverts significant waste from landfills.

These high-performance pellets are used to manufacture a wide array of new automotive parts, including bumpers, dashboards, interior trim, wheel arch liners, and engine covers, effectively closing the loop on automotive plastics.

Veel Gestelde Vragen (FAQ)

1. What types of automotive plastics can be recycled using pelletizing systems?

Modern pelletizing systems, like those from Rumtoo Machine, are versatile enough to process the most common thermoplastics found in vehicles. This includes polypropylene (PP), polyethylene (PE), ABS, and polyamide (PA), even when they contain fillers like talc or glass fibre. The key is effective pre-sorting and cleaning to ensure a relatively pure stream is fed into the system.

2. How does a pelletizing system handle contaminants like paint and coatings?

While heavy contaminants should be removed during the washing phase, advanced pelletizing systems provide a final line of defence. High-capacity melt filters can remove residual solid impurities, while vacuum degassing vents extract inks, moisture, and other volatile contaminants from the molten plastic, ensuring a pure final pellet.

3. Are the mechanical properties of recycled pellets comparable to virgin plastic?

Yes, when processed correctly with advanced equipment. The goal of a high-performance pelletizing system is to minimise thermal and mechanical stress on the polymer. By using optimised screw designs and precise temperature control, systems from Rumtoo Machine can produce recycled pellets that retain excellent mechanical properties, making them suitable for demanding automotive applications.

4. What is the typical return on investment for an in-house automotive plastics pelletizing line?

The ROI can be highly attractive. By converting plastic scrap—which may have been a disposal cost—into a valuable raw material, manufacturers can significantly reduce their expenditure on virgin resins. Factors influencing ROI include the volume of scrap, the market price of virgin polymers, and operational efficiencies. Modern, energy-efficient machines are designed to maximise this return.

Conclusion: Partner with Rumtoo Machine to Drive Your Recycling Forward

The challenge of automotive plastic waste is immense, but the opportunities for innovation are even greater. Advanced pelletizing systems are the key to unlocking the value hidden in this complex waste stream, transforming it from a liability into a cornerstone of the circular economy. By producing high-quality, reliable recycled pellets, these systems empower manufacturers to reduce costs, meet sustainability targets, and contribute to a healthier planet.

[23] Bij Rumtoo Machine, we combine deep industry expertise with state-of-the-art engineering to deliver pelletizing solutions that are powerful, efficient, and tailored to the unique demands of the automotive recycling sector. Our commitment to innovation ensures our clients in the USA, Europe, and beyond are equipped to lead the charge in sustainable manufacturing.

Ready to transform your plastic scrap into a high-value asset? Contact the experts at Rumtoo Machine today to discuss your project or vraag een offerte aan.