Linia do granulacji plastiku BOPP

Rumtoo Machinery specjalizuje się w badaniach i rozwoju oraz produkcji producentów i dostawców linii do granulowania tworzyw sztucznych BOPP. dostawców. Wydajne i zrównoważone przekształcanie odpadów folii BOPP w wysokiej jakości granulki wielokrotnego użytku. w sposób zrównoważony.

Złóż wniosek o indywidualne wycenę

Złóż wniosek o indywidualne wycenę

Rozwiąż wyzwania związane z recyklingiem BOPP

Od mocno zadrukowanych folii po metalizowane skrawki, nasz system zamienia trudne odpady w granulki o wysokiej wartości.

Folia drukowana i metalizowana

Zaawansowane odgazowywanie próżniowe skutecznie usuwa lotne substancje i gazy z metalizowanego lub mocno zadrukowanego BOPP, zapobiegając powstawaniu pęcherzyków powietrza.

15% Niższe koszty energii

Zaprojektowane z myślą o wydajności. Nasze zoptymalizowane systemy napędowe i grzewcze znacznie zmniejszają zużycie energii na tonę produkcji.

Jednolita jakość pelletu

Precyzyjna filtracja i cięcie zapewniają wysoką klarowność, jednolite granulki odpowiednie dla wysokiej klasy folii rozdmuchiwania lub formowania wtryskowego.

Wysoka automatyzacja

Inteligentne sterowanie i stabilne podawanie zmniejszają zapotrzebowanie na siłę roboczą do zaledwie 2 operatorów, usprawniając cały przepływ pracy.

Idealne zastosowania

Zaprojektowany specjalnie dla unikalnych właściwości dwuosiowo orientowanego polipropylenu. Polipropylenu.

Odpady drukarskie BOPP

Idealny do mocno zabarwionych skrawków produkcyjnych i obrzeży z linii drukarskich.

Folia metalizowana

Obsługuje folie BOPP powlekane aluminium z wydajnym odgazowywaniem pozostałości powłoki.

Rolki filmu

Z łatwością przetwarza rolki poza specyfikacją, luźne wykończenia i odpady z rozruchu.

Folie laminowane

Możliwość przetwarzania wielowarstwowych laminatów BOPP/PE w związki wielokrotnego użytku.

Przegląd procesu granulacji BOPP

Specjalistyczna linia Rumtoo Machinery została zaprojektowana do optymalnego przetwarzania folii BOPP zapewniając czystą i wydajną transformację materiału.

-

Pre-kondycjonowanie i Degassing: Odgazowanie następuje w zagęszczarce tnącej, podgrzewanie i wstępne suszenie materiału. Optymalizuje to proces i odciąża strefę odgazowywania ekstrudera. strefę odgazowywania wytłaczarki.

-

Optymalizacja Ekstrudacji: Idealna konstrukcja ślimaka, dostosowana do BOPP, zapewnia wydajne topienie, plastyfikację i homogenizację materiału.

-

System Degassing pod ciśnieniem próżniowym: Wtrącenia gazowe i substancje lotne (zwłaszcza z ciężkich wydrukowanej folii lub wilgotnego materiału) są skutecznie usuwane w dwustrefowym systemie odgazowywania próżniowego system.

-

Filtracja Masy: Tylko dokładnie stopiony, przefiltrowany i homogenizowany materiał gwarantując czystość końcowych granulek.

Kluczowe komponenty linii do granulacji BOPP

Każdy element jest starannie zaprojektowany pod kątem wysokiej wydajności i trwałości, zapewniając bezproblemowy proces recyklingu.

Wytłaczarka zintegrowana z kompaktorem

To urządzenie jest wyposażone w zintegrowany kompaktor tnący, który bezpośrednio przetwarza odpady folii BOPP poprzez cięcie, suszenie i zagęszczanie w celu stabilnego podawania do wytłaczarki.

System cięcia tarczy wody

Zapewnia precyzyjne i wydajne cięcie pelletu. Ostrza obrotowe są montowane pneumatycznie, a ich prędkość prędkość automatycznie dostosowuje się do ciśnienia stopionego materiału, zapewniając stały rozmiar peletu.

System suszenia wibracyjnego

Łączy w sobie zaawansowane sito wibracyjne do odwadniania z poziomym odwadniaczem odśrodkowym do wysokowydajne suszenie i niskie zużycie energii, wytwarzając doskonale wysuszone granulki.

Specyfikacje techniczne

Zobacz parametry wydajności dla naszej gamy maszyn do granulowania tworzyw sztucznych BOPP Maszyny.

| Model | Średnica wału (mm) | Współczynnik L/D | Moc silnika (kW) | Wydajność wyjściowa (kg/h) |

|---|---|---|---|---|

| ML95 | 95 | 30:1 / 32:1 | — | 300 - 450 |

| ML110 | 110 | 30:1 / 32:1 | — | 450 - 650 |

| ML130 | 130 | 30:1 / 32:1 | — | 650 - 900 |

| ML160 | 160 | 30:1 / 32:1 | — | 900 - 1100 |

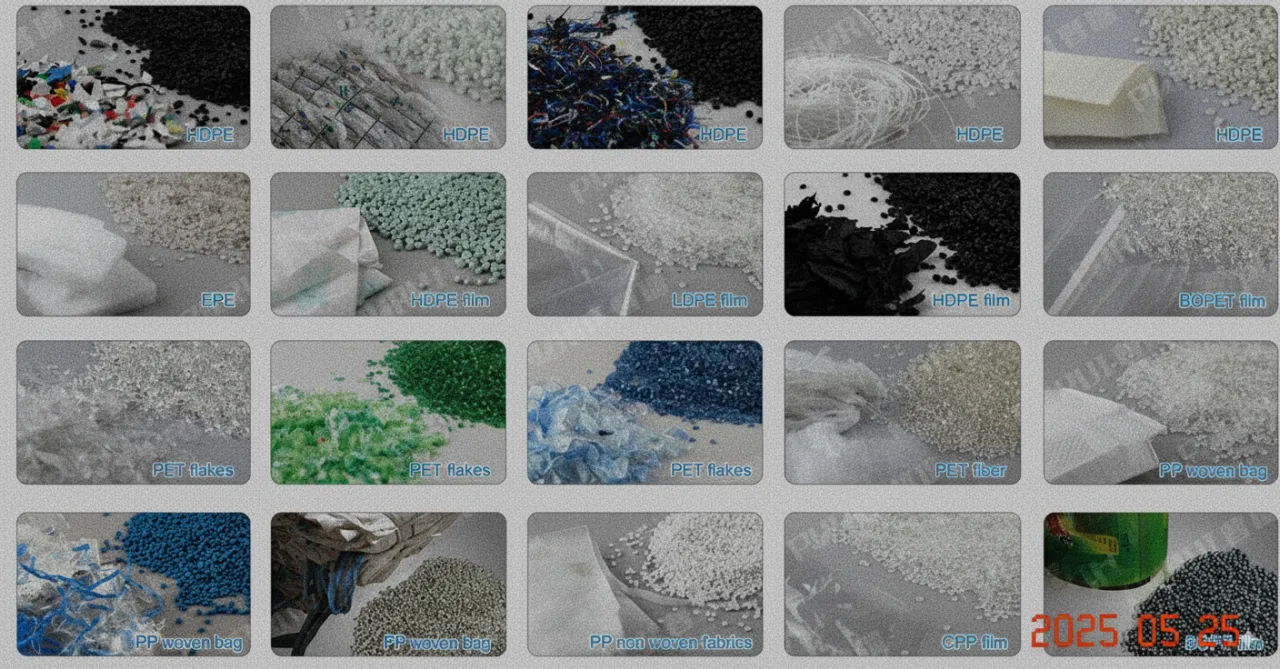

Próbka granulek i Pakowanie

Przekonaj się o jakości produkowanego przez nas granulatu BOPP i naszych profesjonalnych rozwiązań opakowaniowych. rozwiązania.

Gwarancja i instalacja

1-letnią ograniczoną gwarancją

Każda z naszych maszyn do recyklingu jest objęta kompleksową roczną ograniczoną gwarancją, co zapewnia spokój ducha dzięki inwestycji.

Wsparcie instalacyjne ekspertów

Zapewniamy profesjonalne usługi instalacyjne. Nasi doświadczeni inżynierowie mogą odwiedzić Twoją lokalizację, aby pomóc w kompletnym procesie konfiguracji i uruchomienia.

Uzyskaj niestandardową ofertę

Masz pytania lub potrzebujesz dopasowanego rozwiązania? Wyślij nam wiadomość, a nasi eksperci niezwłocznie się z Tobą skontaktują.