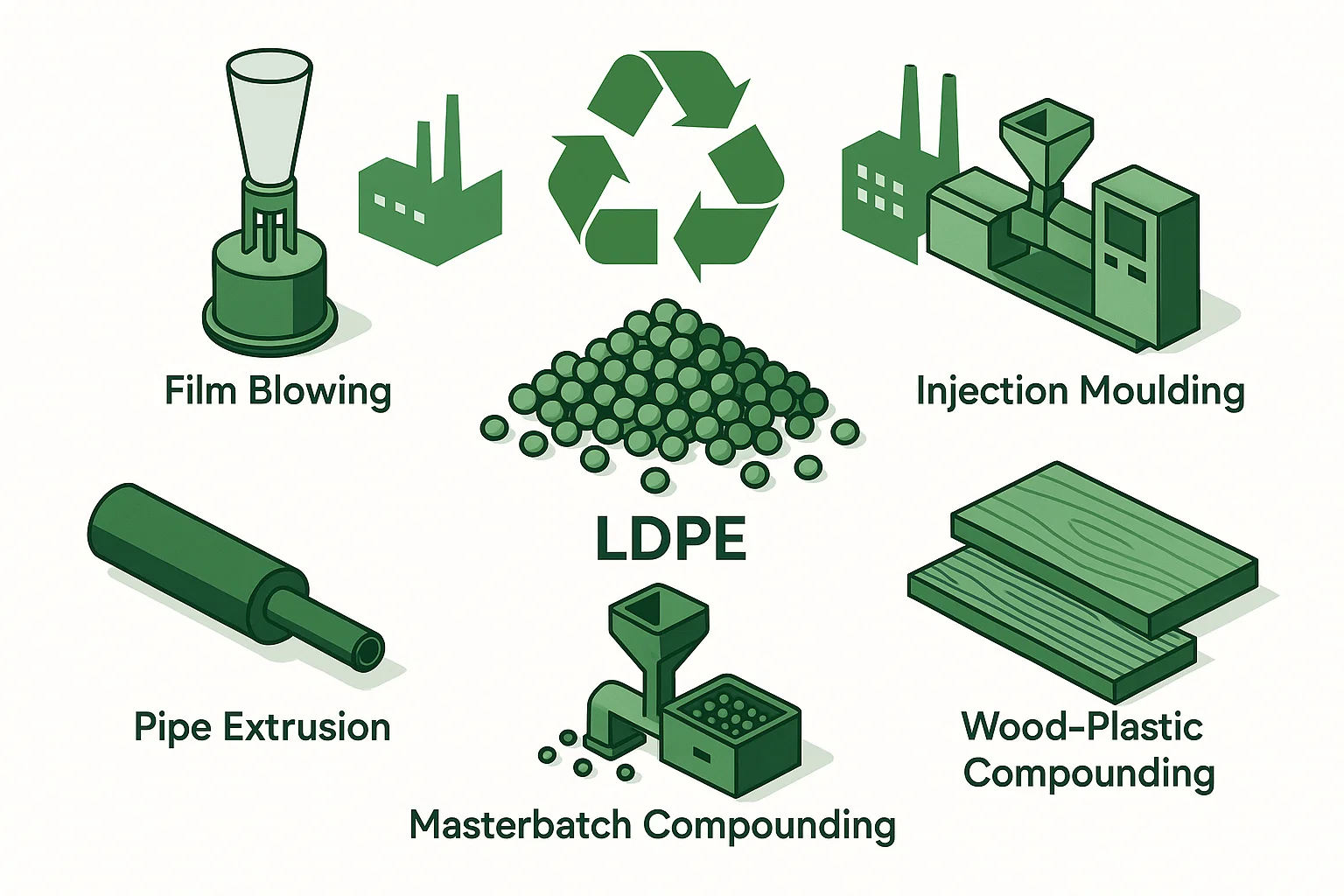

A demanda global por grânulos de Polietileno de Baixa Densidade (LDPE) reciclado está continuamente aumentando, impulsionada pela necessidade urgente de sustentabilidade, conformidade ambiental e soluções de manufatura econômicas. Fabricantes e profissionais da indústria nos EUA e Europa reconhecem o LDPE reciclado como um material bruto versátil e essencial. A Rumtoo Machine possui vasta experiência em fornecer soluções de reciclagem confiáveis, garantindo grânulos de alta qualidade adequados para diversas aplicações industriais.

Por que o Mercado de Grânulos de LDPE Reciclado está em Crescimento

À medida que as indústrias se inclinam para práticas sustentáveis, os grânulos de LDPE reciclado emergiram como um recurso altamente procurado. Sua flexibilidade inerente, durabilidade e custo-effectiveness os tornam indispensáveis em várias áreas de manufatura. Os sistemas de reciclagem avançados da Rumtoo Machine transformam plásticos desperdiçados em grânulos de LDPE de alta qualidade, alinhando-se com padrões ambientais e contribuindo para uma economia circular.

Aplicação 1: Manufatura de Filmagem por Inflação

Um dos usos mais significativos para os grânulos de LDPE reciclado é na produção de filmagem por inflação. Esses filmes são amplamente utilizados para sacos de lixo, filmes agrícolas, embalagens de proteção e mais.

A tecnologia de pelotização da Rumtoo Machine garante que os grânulos possuam características de fusão ideais, essenciais para a produção de filmes inflados consistentes, fortes e confiáveis. Nosso equipamento suporta fabricantes que buscam soluções de embalagem sustentáveis e robustas.

Benefícios-chave:

-

Economia de custos em comparação com plástico virgem

-

Aumento da sustentabilidade

-

Excelente flexibilidade e resistência à tração

Aplicação 2: Moldagem por Injeção

A moldagem por injeção usando grânulos de LDPE reciclado abre oportunidades para a manufatura de vários produtos diários, como baldes, recipientes, caixas e até brinquedos. A estabilidade de processamento superior fornecida pelos grânulos produzidos pelos sistemas da Rumtoo Machine reduz significativamente defeitos de produção e desperdício de material.

Ao incorporar grânulos de LDPE reciclado, os fabricantes podem alcançar:

-

Custos de matérias-primas mais baixos

-

Consistência de produto alta

-

Melhoras nas credenciais ambientais

Aplicação 3: Extrusão de Tubos e Perfis

Pelotas de LDPE reciclado são amplamente utilizadas para extrusão de tubos e perfis duráveis, beneficiando as indústrias da construção e infraestrutura. A tecnologia da máquina Rumtoo controla precisamente as características das pelotas, garantindo que os produtos extrudados atinjam rigorosas especificações e padrões da indústria.

Vantagens incluem:

-

Resistência à corrosão

-

Facilidade de instalação

-

Desempenho confiável a longo prazo

Aplicação 4: Compostagem e Produção de Masterbatch

Fabricantes utilizam amplamente pelotas de LDPE reciclado como materiais básicos para a criação de compostos e masterbatch. Esses materiais personalizados são cruciais para personalizar propriedades como resistência UV, estabilidade de cor e desempenho mecânico melhorado.

Pelotizadores da máquina Rumtoo garantem que os compostos resultantes mantenham qualidade consistente, permitindo que os produtores de masterbatch entreguem produtos superiores de maneira confiável.

Vantagens-chave:

-

Propriedades personalizáveis para diversas aplicações

-

Dispersão uniforme e controle de qualidade

-

Melhoria na eficiência econômica

Aplicação 5: Compostos de Madeira e Plástico (WPC)

Os compostos de madeira e plástico (WPC) estão cada vez mais populares na construção e paisagismo devido à sua durabilidade e sustentabilidade. Pelotas de LDPE reciclado são um ingrediente-chave, proporcionando maior resistência aos elementos ambientais e melhoria na longevidade.

A máquina Rumtoo garante que as pelotas sejam calibradas finamente, assegurando a integração ótima com fibras de madeira para os materiais compostos de maior qualidade.

Benefícios incluem:

-

Aumento da durabilidade e resistência à umidade

-

Economia de custos

-

Fonte de material sustentável

Melhoria Visual: Fluxo de Trabalho e Eficiência

Diagrama Visual: Inclua uma ilustração clara do fluxo de reciclagem de resíduos plásticos até os grânulos de LDPE reciclados usando o equipamento da máquina Rumtoo.

Gráfico de Comparação de Desempenho: Demonstre a qualidade superior dos grânulos, eficiência e consistência dos sistemas da máquina Rumtoo em comparação com métodos tradicionais.

Perguntas Frequentes (FAQs)

1. Os grânulos de LDPE reciclados são tão fortes quanto os materiais virgens?

Sim, grânulos de LDPE reciclados de alta qualidade, especialmente aqueles produzidos com equipamentos avançados como a máquina Rumtoo, podem igualar ou até superar as propriedades dos materiais virgens em várias aplicações.

2. Quais tipos de produtos beneficiam mais com o LDPE reciclado?

Produtos como filmes estirados, itens moldados por injeção, tubos extrudidos, compostos de mestrebatch e compostos de madeira-plástico beneficiam particularmente dos grânulos de LDPE reciclados.

3. Os grânulos de LDPE reciclados podem economizar custos significativamente?

Absolutamente. Os grânulos de LDPE reciclados geralmente oferecem economias significativas em comparação com polímeros virgens, mantendo excelente qualidade e desempenho.

4. Por que escolher o equipamento de moagem da Rumtoo Machine?

A Rumtoo Machine oferece soluções de reciclagem confiáveis e de alto desempenho que garantem consistência, eficiência e qualidade superior dos grânulos, tornando-se a escolha preferida dos fabricantes nos EUA e Europa.

Conclusão

A versatilidade e os benefícios econômicos dos grânulos de LDPE reciclados os tornam um recurso indispensável em diversas aplicações industriais. Para produzir grânulos de alta qualidade adequados para essas aplicações exigentes, você precisa de uma máquina confiável. Veja nossa Máquina de pelotização de único eixo em ação.

Para mais informações ou para solicitar uma cotação personalizada, entre em contato com a Rumtoo Machine hoje. Estamos aqui para apoiar sua jornada rumo a soluções de reciclagem sustentáveis, eficientes e lucrativas.