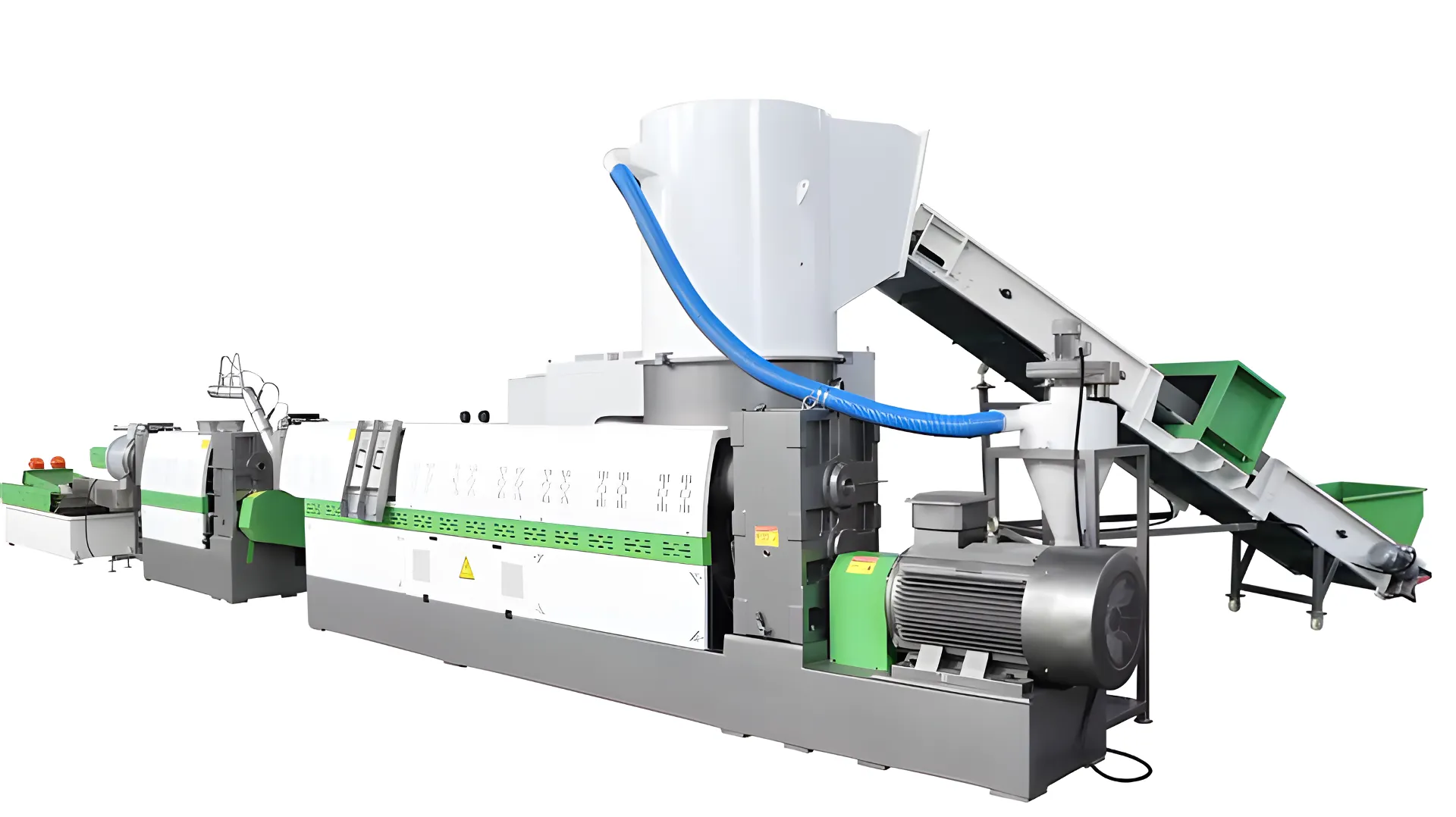

Máquina de Pelotização de Parafuso Simples para Plástico Macio

Struggling with bulky PE/PP film, bags, or factory scrap? The Rumtoo ML Series single-screw pelletizing line is your robust, cost-effective solution to convert low-value waste into a profitable resource.

Solicite uma Cotação PersonalizadaSolve Your Recycling Challenges

Handles Wet Material

Stop worrying about moisture. The integrated compactor and efficient venting system can process washed films with 3-5% moisture content without foaming or degradation.

20% compared to traditional multi-stage systems.Non-Stop Operation

Equipped with a hydraulic screen changer, you can swap filters without stopping the machine, minimizing downtime and keeping your production line moving 24/7.

Ideal Applications

Designed specifically for soft plastics, the ML Series turns these common waste streams into high-value granules.

Post-Industrial Film

Perfect for clean factory scraps, edge trims, and off-cuts of LDPE, LLDPE, and HDPE stretch films.

Washed Agricultural Film

Handles greenhouse films and mulch films that have been washed and squeezed, tolerating residual moisture.

Sacolas de PP Tricotadas

Efficiently densifies and pelletizes crushed raffia bags, cement bags, and jumbo bags (FIBCs).

Crushed Regrinds

Also suitable for pre-crushed rigid plastics like HDPE bottles, crates, and pipe flakes mixed with films.

Nosso Processo de 4 Passos

Alimentação e Compactação

Material is fed via conveyor into the compactor, where it’s cut, mixed, and densified for stable feeding.

Extrusão e Desgaseificação

The densified material is forced into the single-screw extruder, then melted, plasticized, and vacuum degassed.

Filtragem e Pelotização

Molten plastic is filtered for impurities and then cut into uniform pellets by a water-ring pelletizing system.

Secagem e Coleta

As pelotas são rapidamente desidratadas e enviadas para um silo para resfriamento, embalagem e armazenamento.

Veja a Série ML em Ação

From tangled film to uniform pellets. Watch our machine deliver efficiency and quality in under 90 seconds.

Especificações Técnicas

| Modelo | Compactor | Extrusora de parafuso único | Capacidade (kg/h) | |||

|---|---|---|---|---|---|---|

| Effective Volume (L) | Potência do Motor (KW) | Diâmetro do Parafuso (mm) | Relação L/D | Potência do Motor (KW) | ||

| ML85-100 | 300 | 37-45 |

85

100

|

28-33:1

10:1

|

55-75 | 150-200 |

| ML100-120 | 500 | 55-75 |

100

120

|

28-33:1

10:1

|

90-110 | 250-350 |

| ML130-150 | 800 | 90-110 |

130

150

|

28-33:1

10-12:1

|

132-160 | 400-550 |

| ML150-160 | 950 | 110-132 |

150

160

|

28-33:1

12:1

|

185-200 | 500-650 |

| ML160-180 | 1100 | 110-132 |

160

180

|

28-33:1

12:1

|

220-250 | 700-900 |

| ML180-200 | 1100 | 160-185 |

180

200

|

28-33:1

12:1

|

280-315 | 900-1200 |

* Specifications subject to change without notice.

Galeria de Equipamentos

“The Rumtoo ML-130 has been the workhorse of our film recycling operation. It’s reliable, efficient, and the pellet quality has allowed us to access higher-value markets. The support from their team was first-class.”

Warranty & Installation

Garantia Limitada de 1 Ano

Each of our recycling machines includes a comprehensive one-year limited warranty, giving you peace of mind with your investment.

Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Obtenha sua Solução Personalizada e Cotação

Our experts will analyze your material and production needs to provide a tailored solution and a competitive quote within 24 hours.