fixed price of€125kfor 500 kg/h*

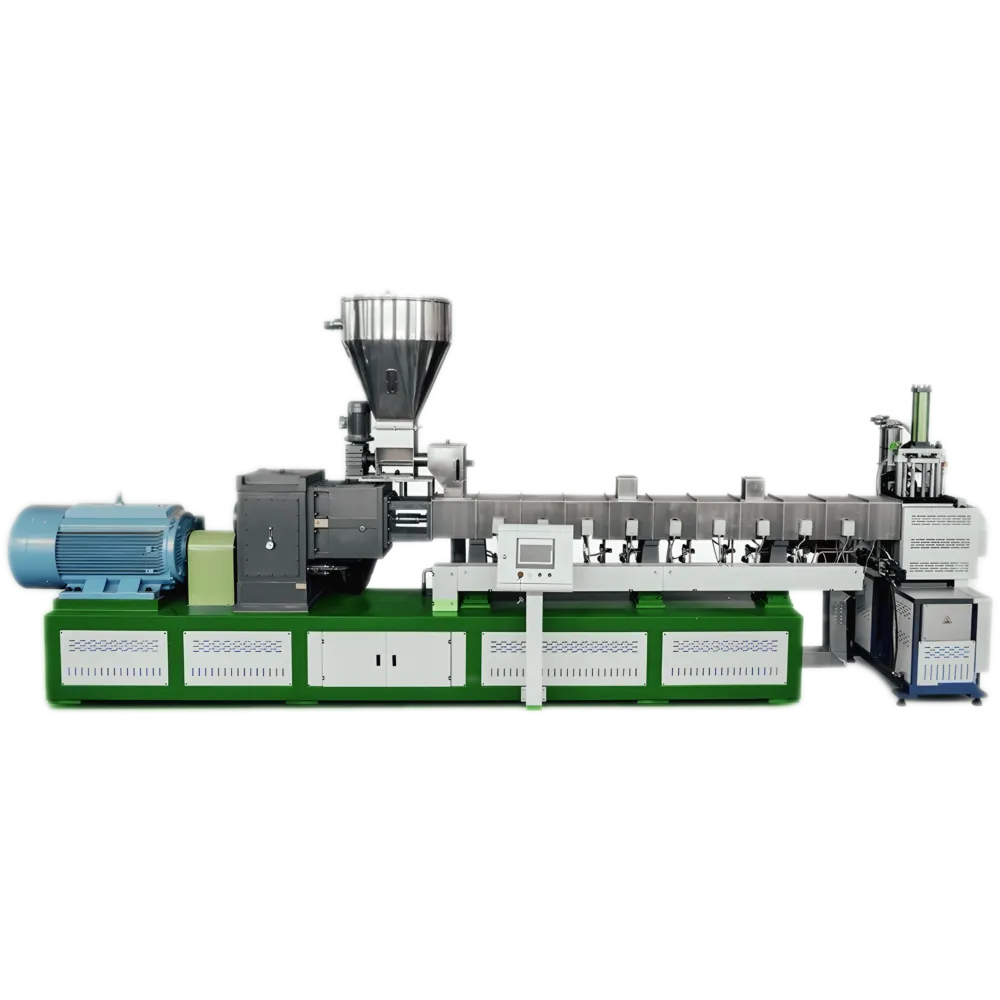

RTechFlow

Our Flexible All-Rounder

- ✓ Ideal for medium contamination levels

- ✓ SW/RTF melt filter

fixed price of€160kfor 500 kg/h*

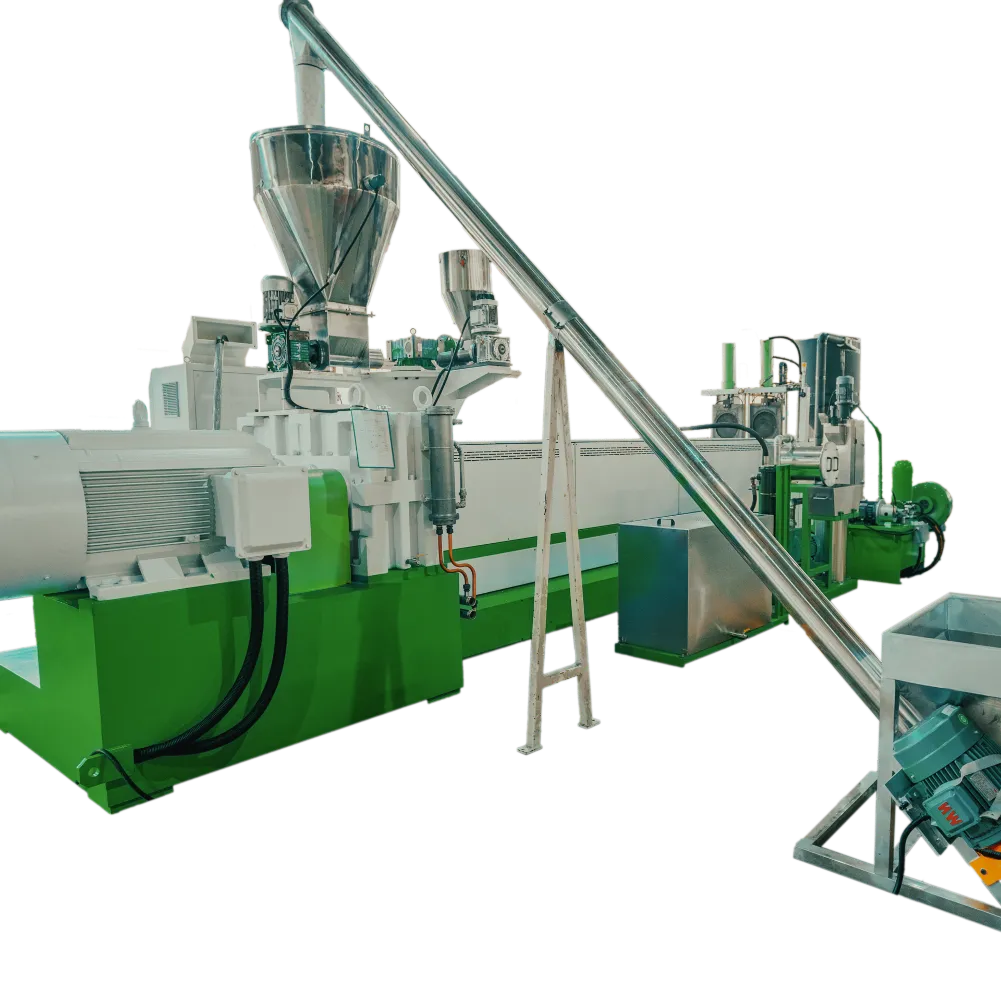

RTechSphere

[Heavy Duty]

For Heavy Contamination

- ✓ Ideal for heavy contamination

- ✓ Rumtoo laser filter

Our Pelletizing Systems

Industry-leading technology for every application

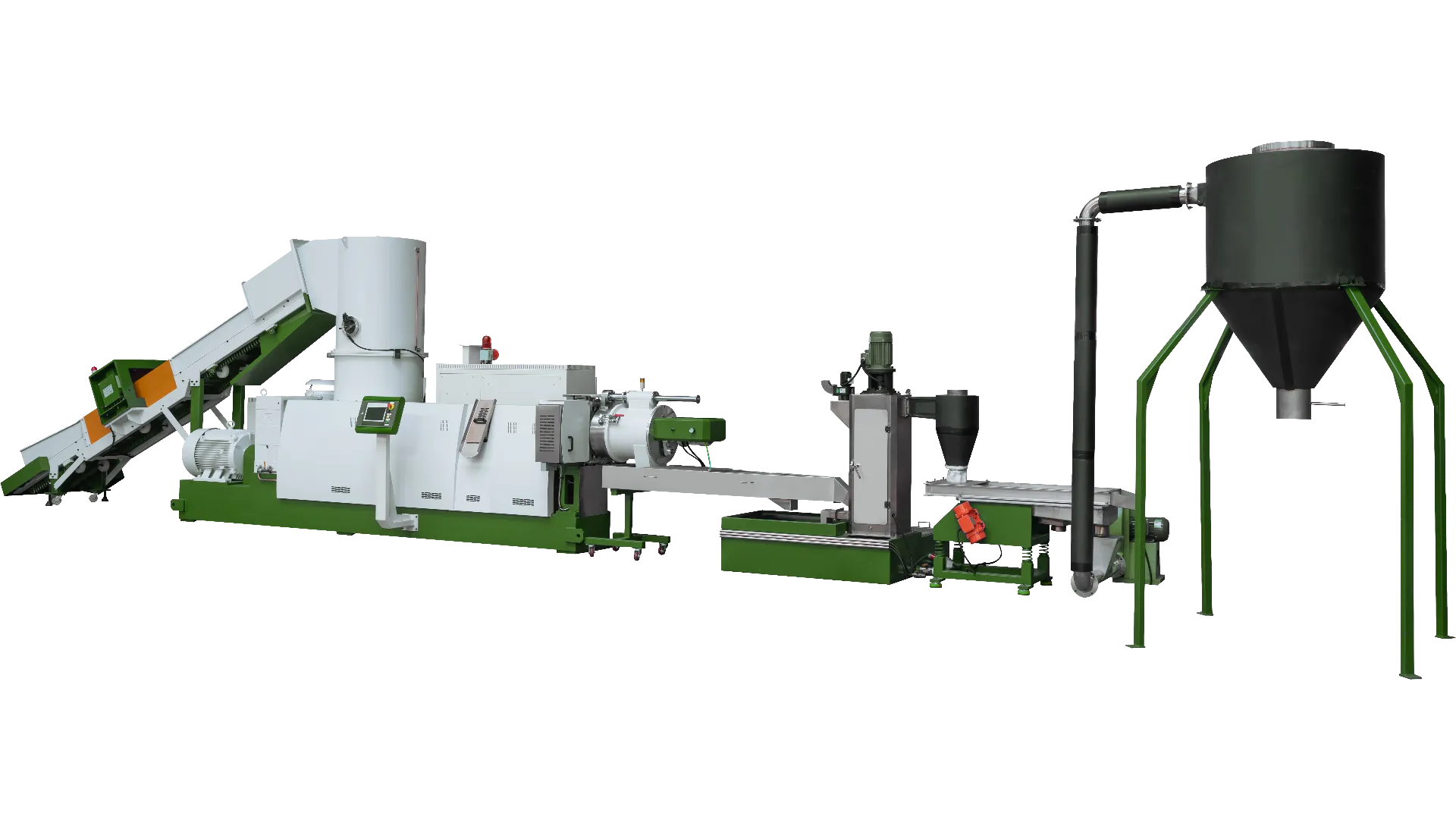

RTechFlow™ Single Screw Pelletizer

Reliable and cost-effective pelletizing solution for processing virgin polymers and clean recycled materials.

- Throughput: 100-1,200 kg/h

- Energy-efficient (0.12-0.25 kWh/kg)

- Simple operation and maintenance

- Lower initial investment

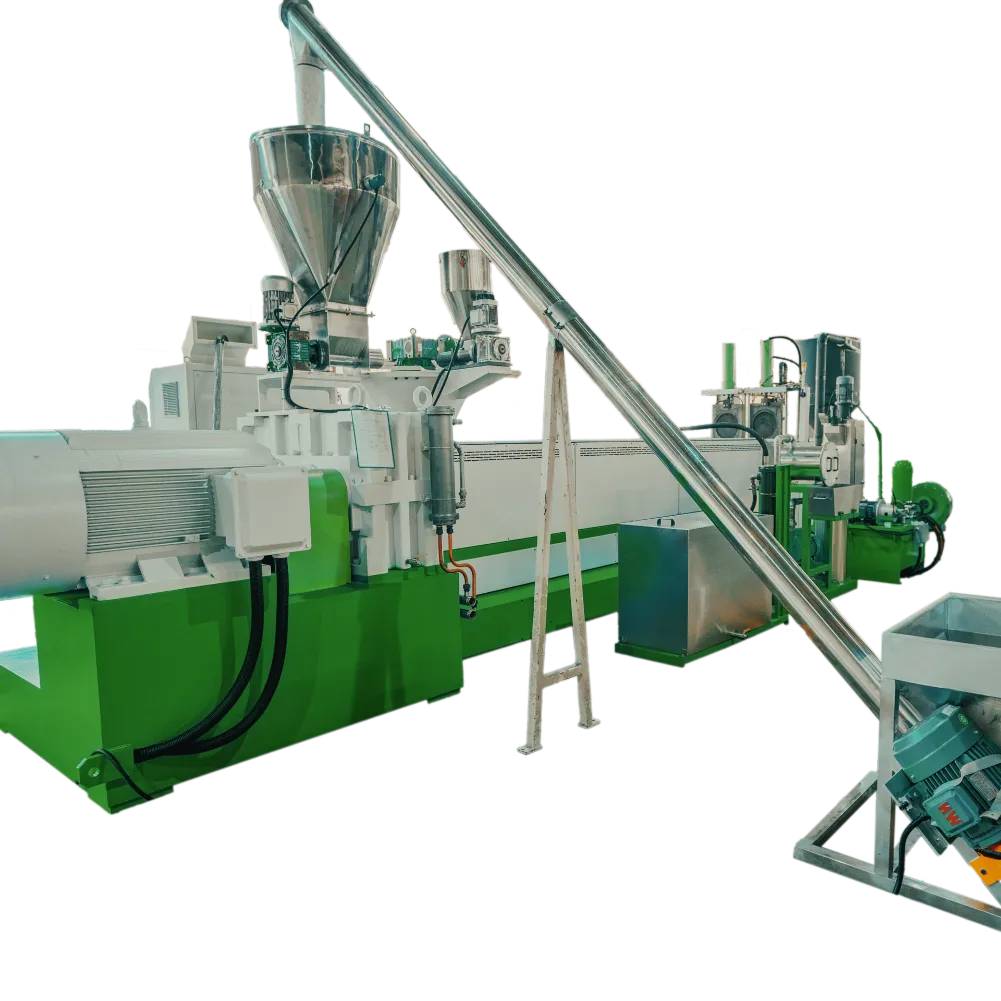

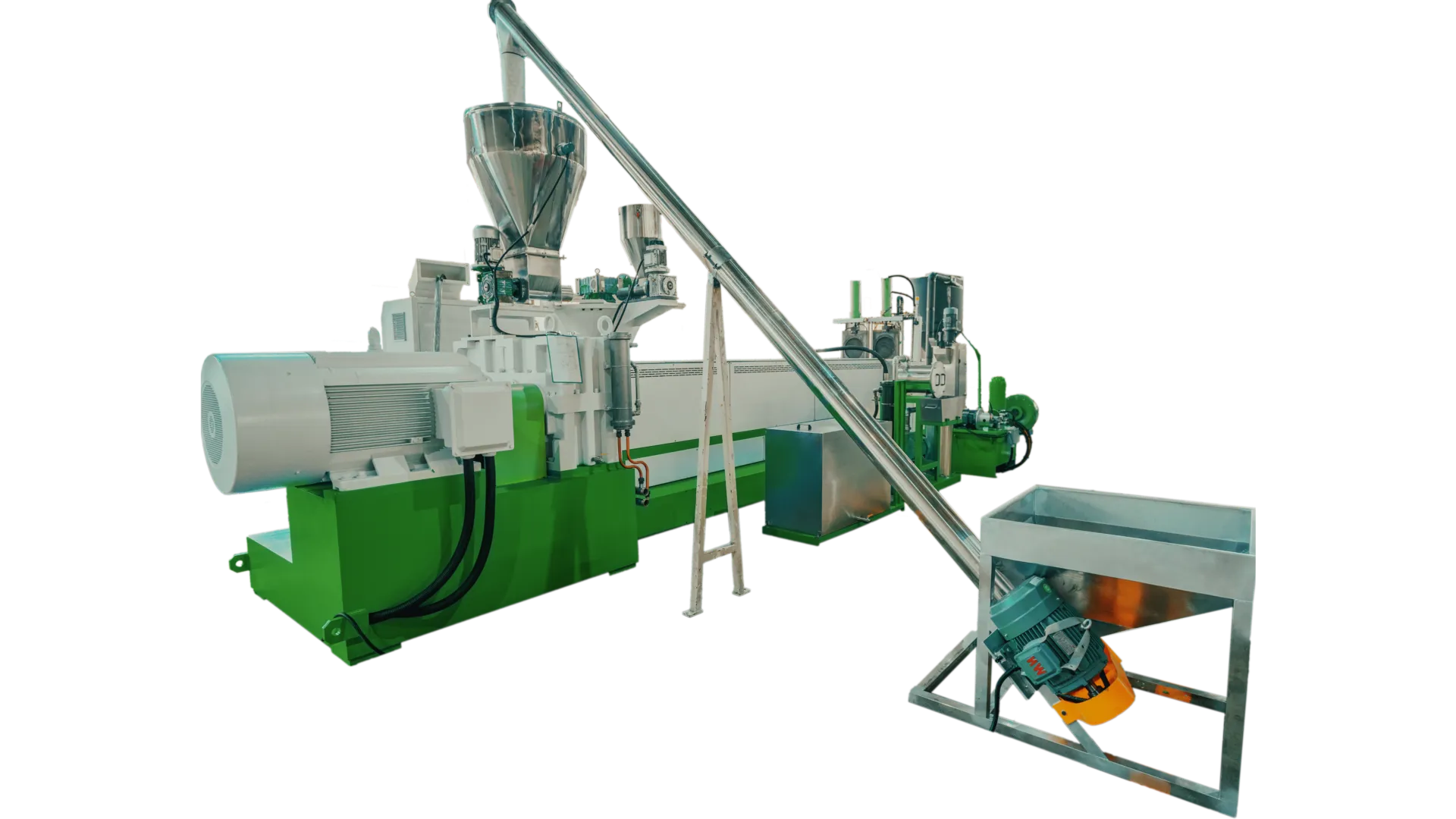

RTechMix™ Twin Screw Extruders

Superior mixing and versatility for compounding operations and processing challenging recycled materials.

- Throughput: 40-1,500 kg/h

- Excellent mixing and degassing

- Handles highly filled compounds

- Modular screw design

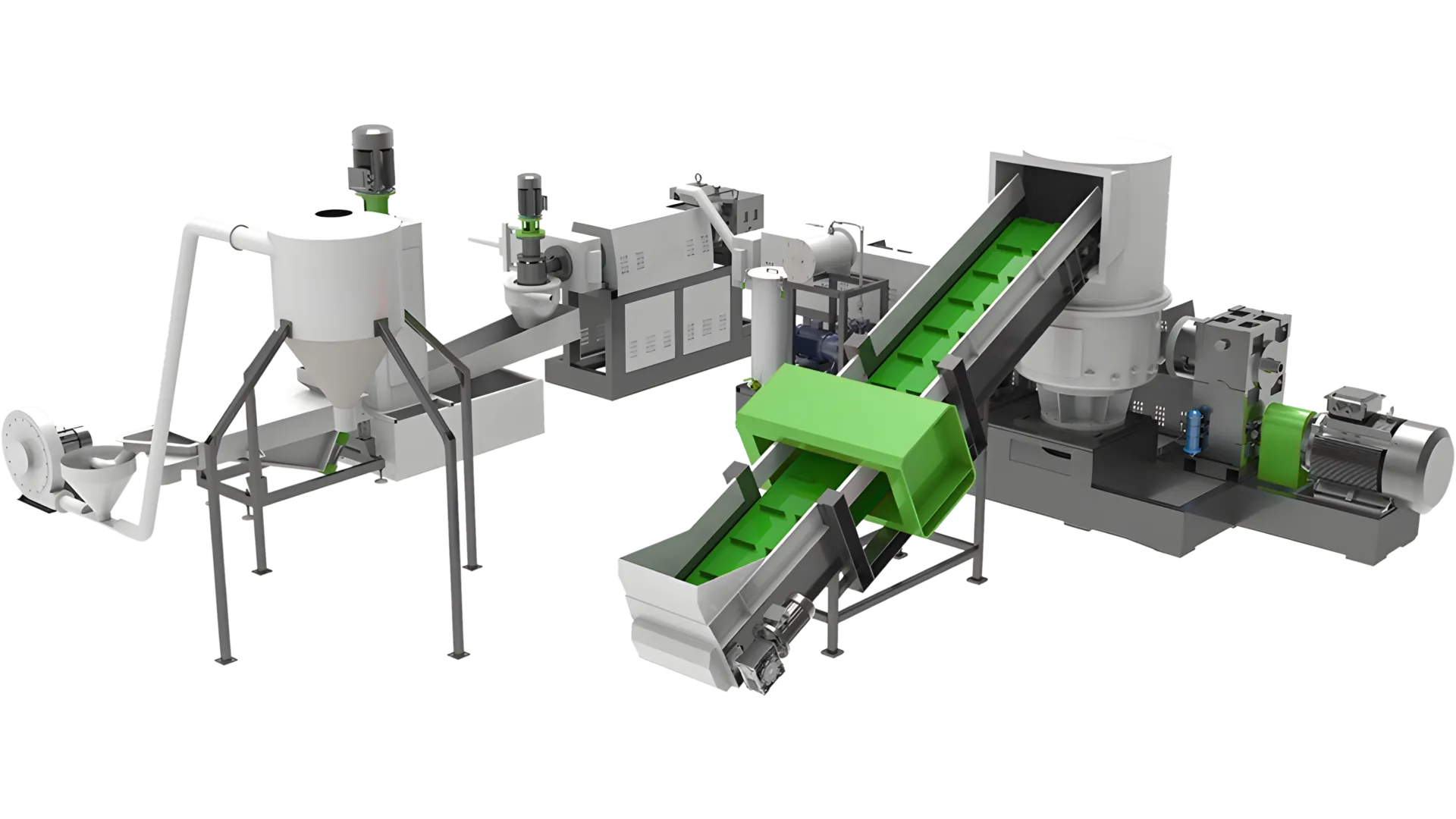

RTechSphere™ Cutter Compactor

Premium pellet quality with spherical shape, immediate cooling, and continuous high-volume production.

- Throughput: 150-12,00 kg/h

- Superior pellet quality

- Ideal for heat-sensitive materials

- Medical and food-grade applications

Why Choose Rumtoo Systems?

Industry-leading advantages that boost your bottom line

Energy Efficiency

Leveraging advanced motor technology and optimized control, our system leads in energy efficiency—cutting operating costs by up to 30%. For example, our single-screw extruder consumes as little as 0.12 kWh/kg, delivering significant electricity savings and reducing your carbon footprint.

Maintenance Friendly

Designed with quick-access components and tool-free blade replacement to minimize downtime and reduce maintenance costs. This allows your team to stay focused on production, not repairs.

High Throughput

Engineered for high throughput through advanced design, our system maintains consistent pellet quality while meeting the demands of everything from small batch runs to large-scale continuous production.

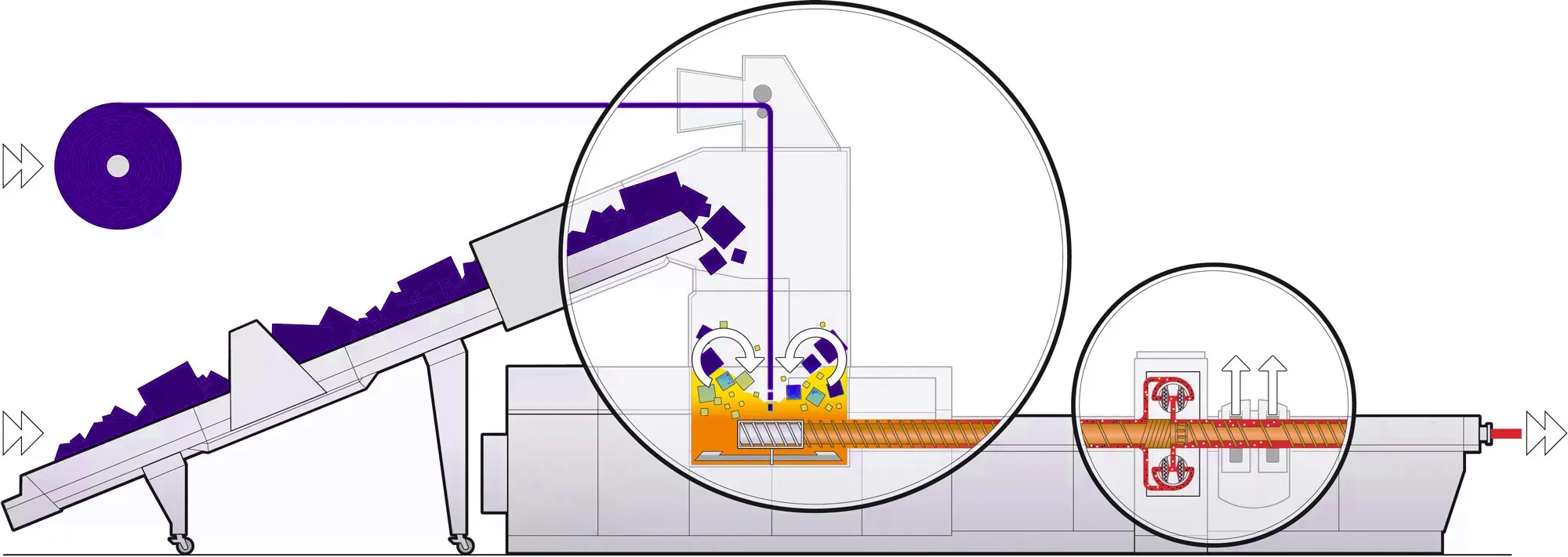

How Our ReadyMac Plastic Recycling System Works

Our patented Rumtoo extruder system makes light work of even the most difficult materials, such as heavily printed films and high-moisture plastics.

In a single, highly efficient step, our system integrates three crucial processes:

- Ultra-fine filtration to remove impurities.

- Melt homogenization for consistent quality.

- High-performance degassing to eliminate gases and moisture.

The genius behind this lies in our TVE technology, which reverses the traditional process. By placing filtration before degassing, we remove contaminants at the most effective stage, guaranteeing a final product of the absolute highest quality.

One Machine, Endless Materials

Stop investing in specialized, expensive equipment for every material type. The ReadyMac, powered by our innovative multi-purpose screw, gives you the ultimate flexibility to process a broad spectrum of plastics without costly changeovers.

It reliably handles various polymers and forms, whether contaminated or printed, including:

- PE (Polyethylene): Such as washed LDPE, agricultural film, and film flakes.

- PP (Polypropylene): Including printed films and non-woven fabrics with solid contaminants.

- PS (Polystyrene): Including rigid packaging (e.g., yogurt cups) and appliance housings.

- PC (Polycarbonate): Commonly found in water cooler bottles, CDs/DVDs, and electronic components.

- PA 6.0 (Polyamide): Such as end-of-life fishing nets, post-industrial fibers, and carpets.

With this impressive versatility, the ReadyMac sets new standards for a more sustainable and profitable future.

Filter Systems of Our Plastic Recycling Plant

The ReadyMac and ReadyMac HD are equipped with two different filter systems that define their unique capabilities.

Technical Specifications

Detailed performance parameters for our pelletizing systems

| Parameter | RTF-120 | RTF-150 | RTF-180 | RTF-200 |

|---|---|---|---|---|

| Throughput (kg/h) | 200-350 | 400-650 | 700-900 | 1,200-1,500 |

| Screw Diameter (mm) | 120 | 160 | 180 | 200 |

| L/D Ratio | 33:1 | 33:1 | 33:1 | 33:1 |

| Motor Power (kW) | 90-110 | 130-160 | 220-250 | 280-320 |

| Energy Consumption (kWh/kg) | 0.22-0.25 | 0.18-0.22 | 0.15-0.18 | 0.12-0.15 |

| Parameter | RTM-35 | RTM-52 | RTM-75 | RTM-95 |

|---|---|---|---|---|

| Throughput (kg/h) | 40-80 | 150-250 | 400-700 | 550-1500 |

| Screw Diameter (mm) | 35.6 | 51.4 | 71 | 93 |

| L/D Ratio | 32-64 | 32-64 | 32-64 | 32-64 |

| Drive Power (kW) | 18.5 | 55 | 132 | 315 |

| Speed(rpm) | 600 | 600 | 500 | 500 |

| Parameter | RTS-120 | RTS-150 | RTS-180 | RTS-200 |

|---|---|---|---|---|

| Throughput (kg/h) | 200-350 | 400-550 | 700-900 | 1,000-1,200 |

| Die Plate Diameter (mm) | 150 | 200 | 300 | 450 |

| L/D Ratio | 33:1 | 33:1 | 33:1 | 33:1 |

| Motor Power (kW) | 90-110 | 130-160 | 220-250 | 280-315 |

| Water Circulation (m³/h) | 4 | 10 | 25 | 60 |

Powerful machine, great price!

Now that’s smart!

Do you have questions about the advantages of our immediately available ReadyMac plastic recycling system?

Our experienced consulting team is always available to assist you.

Get In Touch

Have questions? Fill out the form below and we’ll get back to you shortly.