Introduction: Building the Foundation for a Successful Recycling Operation

As the global economy shifts towards sustainability, the plastic recycling sector has emerged as a critical and highly valuable industry. For entrepreneurs and established corporations alike, launching a recycling plant offers the opportunity to generate significant revenue while making a positive environmental impact. However, success in this field is built on a foundation of a well-planned, efficient, and technologically sound production line.

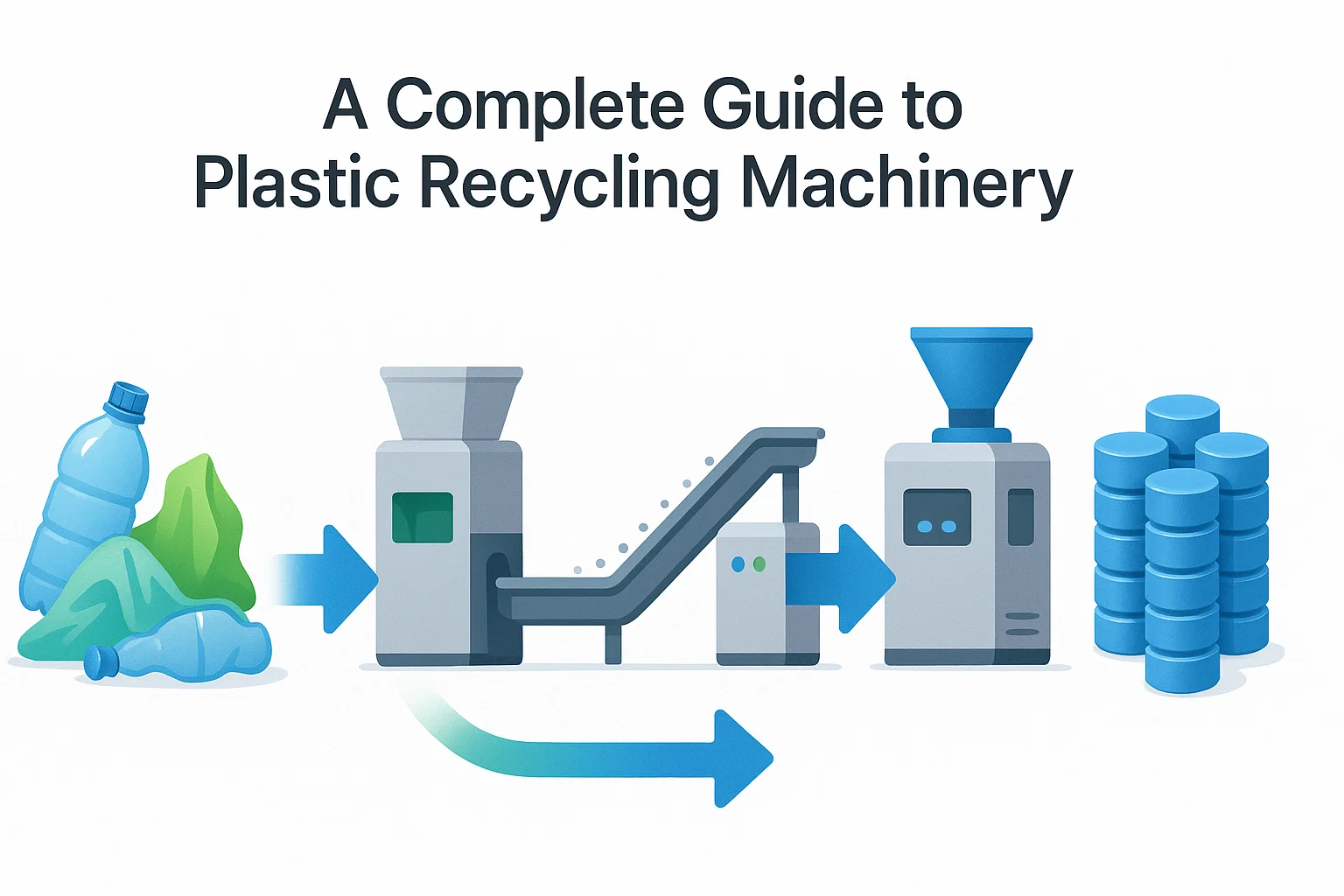

Understanding the specific function of each piece of equipment is the first step toward designing a facility that can effectively transform plastic waste into a high-purity, marketable commodity. This definitive guide outlines the essential machinery required to start a modern plastic recycling plant, broken down by each critical stage of the process.

The Critical First Step: Defining Your Plastic Feedstock

Before a single machine is purchased, the most crucial decision is to identify the primary type of plastic you will process. The equipment required to recycle rigid PET (Polyethylene Terephthalate) bottles is fundamentally different from the machinery needed for post-industrial LDPE (Low-Density Polyethylene) film. Your choice of feedstock will dictate the entire configuration of your plant.

- For Rigid Plastics (e.g., PET Bottles, HDPE Jugs, PP Containers): The focus is on robust size reduction, effective label and contaminant removal, and separation by density.

- For Soft Plastics (e.g., LDPE/LLDPE Film, PP Woven Bags): The challenges lie in efficient feeding of light material, thorough washing, and specialized extrusion systems to handle inks and moisture.

Once your target material is defined, you can assemble your equipment line with precision.

Core Machinery: A Stage-by-Stage Breakdown

A complete, industrial-scale recycling line is an integrated system. Below are the machines required for each stage.

Stage 1: Infeed, Sorting, and Pre-Processing

The objective of this stage is to prepare the raw waste for downstream processing by liberating the material and removing primary contaminants.

- Bale Breaker: If processing post-industrial or post-consumer waste, it will likely arrive in compressed bales. The bale breaker tears these bales apart to create a consistent, single-stream flow of material.

- Sorting Conveyor & Platform: A long conveyor belt where manual or automated (optical) sorting occurs. This is where workers or sensors remove incorrect plastic types, different colors, and gross contaminants like wood, metal, and paper.

- Trommel Screen: A large, rotating sieve that removes small, loose contaminants such as dirt, sand, glass, and bottle caps.

- Metal Detector / Separator: An essential safety feature. This system detects and ejects any ferrous or non-ferrous metal pieces to prevent catastrophic damage to high-speed shredders and granulators.

Stage 2: Size Reduction

The material must be shredded into smaller, uniform pieces to enable effective washing and processing.

- Shredder: A low-speed, high-torque machine that performs the initial size reduction. Single-shaft shredders are highly versatile, while dual-shaft shredders are used for extremely tough or bulky materials.

- Granulator (or Crusher): A high-speed machine that takes plastic pieces and reduces them further into small, consistently sized flakes or “regrind.” The final flake size is determined by the dimensions of a removable screen within the machine.

Stage 3: High-Intensity Washing and Separation

This stage is critical for producing a pure, high-value end product.

- Friction Washer: A high-speed screw washer that uses mechanical friction to scrub dirt and other contaminants from the surface of the plastic flakes.

- Float-Sink Tank: Essential for PET bottle recycling. This large tank uses water density to separate materials. The heavier PET flakes sink, while the lighter PP/PE from caps and label fragments float, allowing them to be skimmed off.

- Hot Washer: Uses hot water and detergents to break down and remove more stubborn contaminants like glue (from labels), grease, and oil residues.

Stage 4: Drying

Moisture must be almost entirely removed before the material can be extruded.

- Mechanical (Centrifugal) Dryer: Uses centrifugal force to violently spin the water off the surface of the flakes, achieving a moisture level of around 2-3%.

- Thermal Drying System: A hot air drying system that removes the final traces of moisture, bringing the humidity level down to below 1%—a critical requirement for high-quality pelletizing.

Stage 5: Extrusion and Pelletizing

This is the final transformation, converting clean flakes into uniform, dense pellets ready for manufacturing.

- Extruder: The core of the pelletizing process. Flakes are fed into the extruder, where a rotating screw melts, mixes (compounds), and builds pressure.

- Note: The type of extruder is critical. For soft films, a Cutter-Compactor Feeder is often integrated to ensure consistent feeding. For printed materials, a Vented Extruder with a degassing system is necessary to remove ink volatiles.

- Melt Filtration System: A screen changer that removes any remaining solid impurities (metal, carbon, etc.) from the molten plastic.

- Pelletizer: A cutting system that takes the strands of molten plastic exiting the die and cuts them into uniform pellets. A Water-Ring Pelletizer is a common, efficient choice for polyolefins.

- Cooling System & Storage Silo: The newly cut pellets are cooled by water and air, then pneumatically conveyed to a large storage silo, ready for bagging.

Conclusion: Your Plant’s Success Depends on an Integrated Solution

Building a plastic recycling plant is a significant investment. While individual machines are important, the ultimate success and profitability of your operation depend on how these components are integrated into a single, seamless, and automated line. The right machinery, configured correctly for your specific feedstock, is what separates a basic operation from a world-class facility.

At Rumtoo, we specialize in more than just manufacturing equipment. We deliver complete, turnkey solutions engineered for performance, reliability, and the highest quality output. Our team of experts is ready to partner with you to design a plant that meets your business objectives and contributes to a truly circular economy.

Ready to turn plastic waste into a valuable asset? Contact the Rumtoo team today to discuss your project and receive a customized equipment proposal.