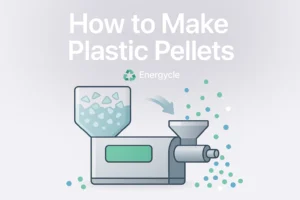

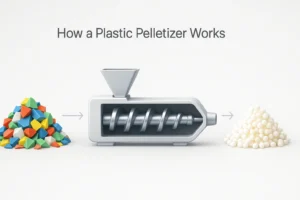

The Ultimate Guide to Recycling Soft Plastics: How to Profitably Process PP/PE Film

Soft plastics like PP and PE film are a major recycling challenge, often ending up in landfills. This definitive guide details the industrial pelletizing process, breaking down each essential step from sorting and washing to extrusion. Learn how the right technology transforms this difficult waste stream into a high-value, reusable commodity.

![How Much Does a Plastic Pelletizing Machine Cost? [2025 Guide]](https://plasticpelletizer.net/wp-content/uploads/2025/06/How-Much-Does-a-Plastic-Pelletizing-Machine-Cost-2025-Guide-300x200.webp)