Water Ring Plastic Pelletizers: The Complete Guide for Industrial Recycling Equipment Buyers

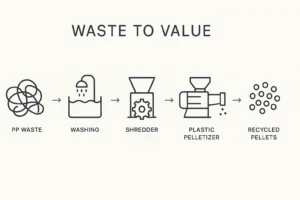

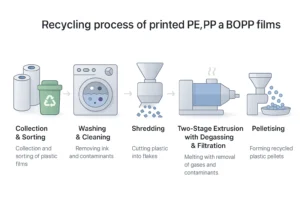

Water ring plastic pelletizers offer a high-efficiency solution for converting plastic waste into premium recycled pellets. Learn how this technology supports scalable, automated, and sustainable recycling operations.