What Pelletizer Do I Need for Multi-Layer and Composite Films?

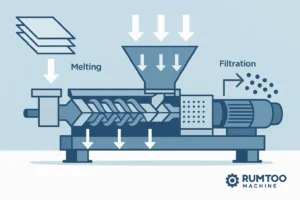

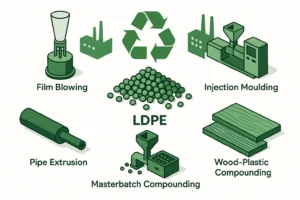

Discover how Rumtoo Machine’s Composite Film Pelletizing Machine tackles the challenges of multi-layer and composite film recycling—featuring custom twin-screw design, multi-stage filtration, and energy-efficient extrusion to deliver uniform, high-quality pellets at industrial scale.