PP Woven Bag Pelletizing Machine in Operation

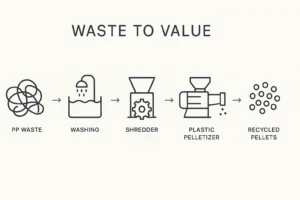

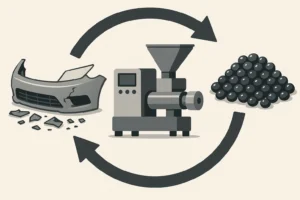

This video features our specialized pelletizing line engineered for PP (Polypropylene) woven materials. Witness the entire process as post-industrial PP woven bags and raffia scrap are efficiently transformed into high-quality, dense, and uniform pellets, perfect for reintroduction into manufacturing. Category: PP Raffia / Woven Duration: 01:23