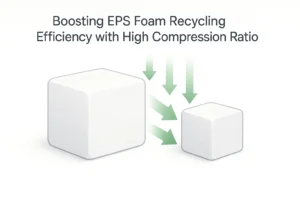

The Complete Business Guide to EPS Foam Recycling in 2025

While most see bulky Styrofoam as an environmental headache, savvy entrepreneurs see a profitable business opportunity. This comprehensive guide provides a complete roadmap for launching a successful EPS recycling venture in 2025, covering everything from market analysis and equipment selection to a step-by-step ROI calculation.