BOPP Plastic Pelletizing Line

Rumtoo Machinery specializes in R&D and production of BOPP plastic pelletizing line manufacturers and suppliers. Transform your BOPP film waste into high-quality, reusable pellets efficiently and sustainably.

Request a Custom Quote

Request a Custom Quote

Solve Your BOPP Recycling Challenges

From heavily printed films to metallized scraps, our system turns difficult waste into high-value pellets.

Process Printed & Metallized Film

Advanced vacuum degassing effectively removes ink volatiles and gas from metallized or heavily printed BOPP, preventing bubbles.

15% Lower Energy Costs

Engineered for efficiency. Our optimized drive and heating systems significantly reduce power consumption per ton of output.

Uniform Pellet Quality

Precision filtration and cutting ensure high-clarity, uniform granules suitable for high-end film blowing or injection molding.

Highly Automated

Smart controls and stable feeding reduce labor requirements to just 2 operators, streamlining your entire workflow.

Ideal Applications

Designed specifically for the unique properties of Biaxially Oriented Polypropylene.

BOPP Printing Waste

Ideal for heavily inked production scraps and edge trims from printing lines.

Metallized Film

Handles aluminum-coated BOPP films with efficient degassing of coating residues.

Film Rolls

Easily processes off-spec rolls, loose trims, and start-up waste.

Laminated Films

Capable of processing multi-layer BOPP/PE laminates into reusable compounds.

BOPP Pelletizing Process Overview

Rumtoo Machinery’s specialized line is designed for optimal processing of BOPP film, ensuring clean and efficient material transformation.

-

Pre-conditioning & Degassing: Degassing occurs in the cutter compactor, preheating and predrying the material. This optimizes the process and relieves the extruder’s degassing zone.

-

Optimized Extrusion: An ideal screw design, tailored for BOPP, ensures efficient melting, plasticizing, and homogenization of the material.

-

Vacuum Degassing System: Gas inclusions and volatiles (especially from heavy printed film or moist material) are effectively removed in the double-zone vacuum degassing system.

-

Melt Filtration: Only thoroughly melted, filtered, and homogenized material passes through, guaranteeing the purity of the final pellets.

Key Components of the BOPP Pelletizing Line

Each component is meticulously designed for high performance and durability, ensuring a seamless recycling process.

Compactor-Integrated Extruder Unit

This unit features an integrated cutter compactor that directly processes BOPP film scrap by cutting, drying, and compacting it for stable feeding into the extruder.

Water-ring Die-face Cutting System

Ensures precise and efficient pellet cutting. Rotary blades are pneumatically fitted and their speed automatically adjusts based on melt pressure for consistent pellet size.

Vibration Drying System

Combines an advanced dewatering vibration sieve with a horizontal centrifugal dewaterer for high-performance drying and low energy consumption, producing perfectly dried pellets.

Technical Specifications

View the performance parameters for our range of BOPP Plastic Pelletizing Machines.

| Model | Screw Diameter (mm) | L/D Ratio | Motor Power (kW) | Output Capacity (kg/h) |

|---|---|---|---|---|

| ML95 | 95 | 30:1 / 32:1 | — | 300 – 450 |

| ML110 | 110 | 30:1 / 32:1 | — | 450 – 650 |

| ML130 | 130 | 30:1 / 32:1 | — | 650 – 900 |

| ML160 | 160 | 30:1 / 32:1 | — | 900 – 1100 |

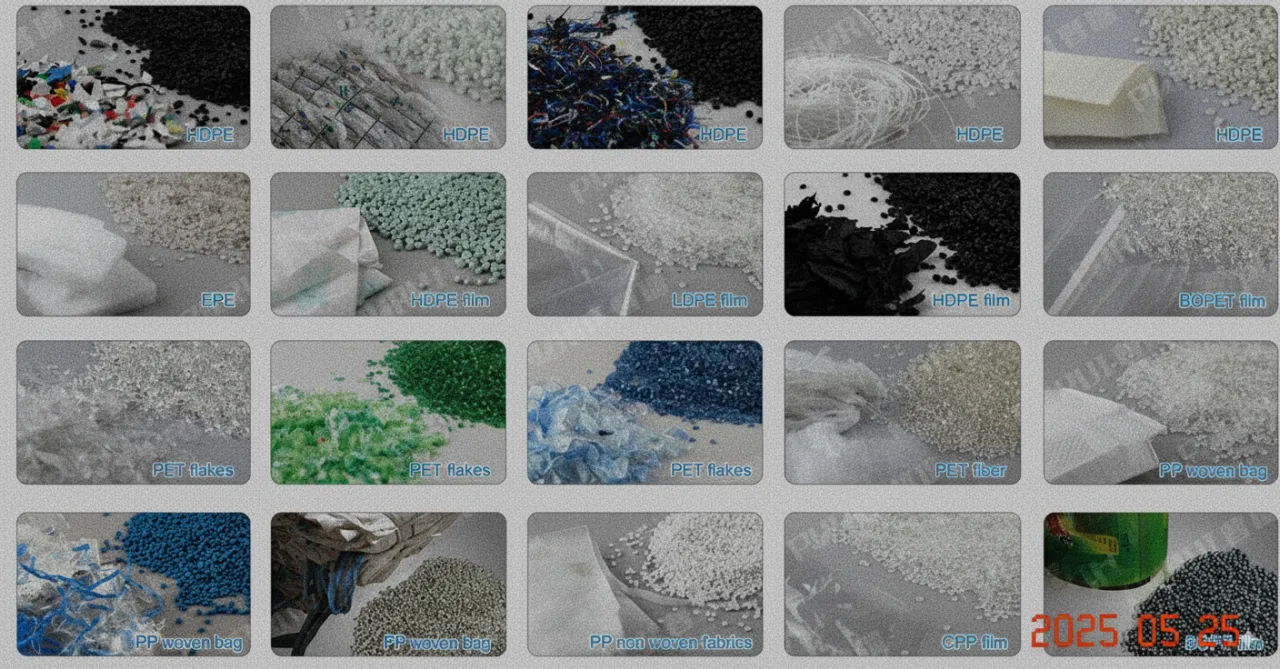

Pellets Sample & Packaging

Witness the quality of our produced BOPP pellets and our professional packaging solutions.

Warranty & Installation

1-Year Limited Warranty

Each of our recycling machines includes a comprehensive one-year limited warranty, giving you peace of mind with your investment.

Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Get a Custom Quote

Have questions or need a tailored solution? Send us a message, and our experts will get back to you promptly.