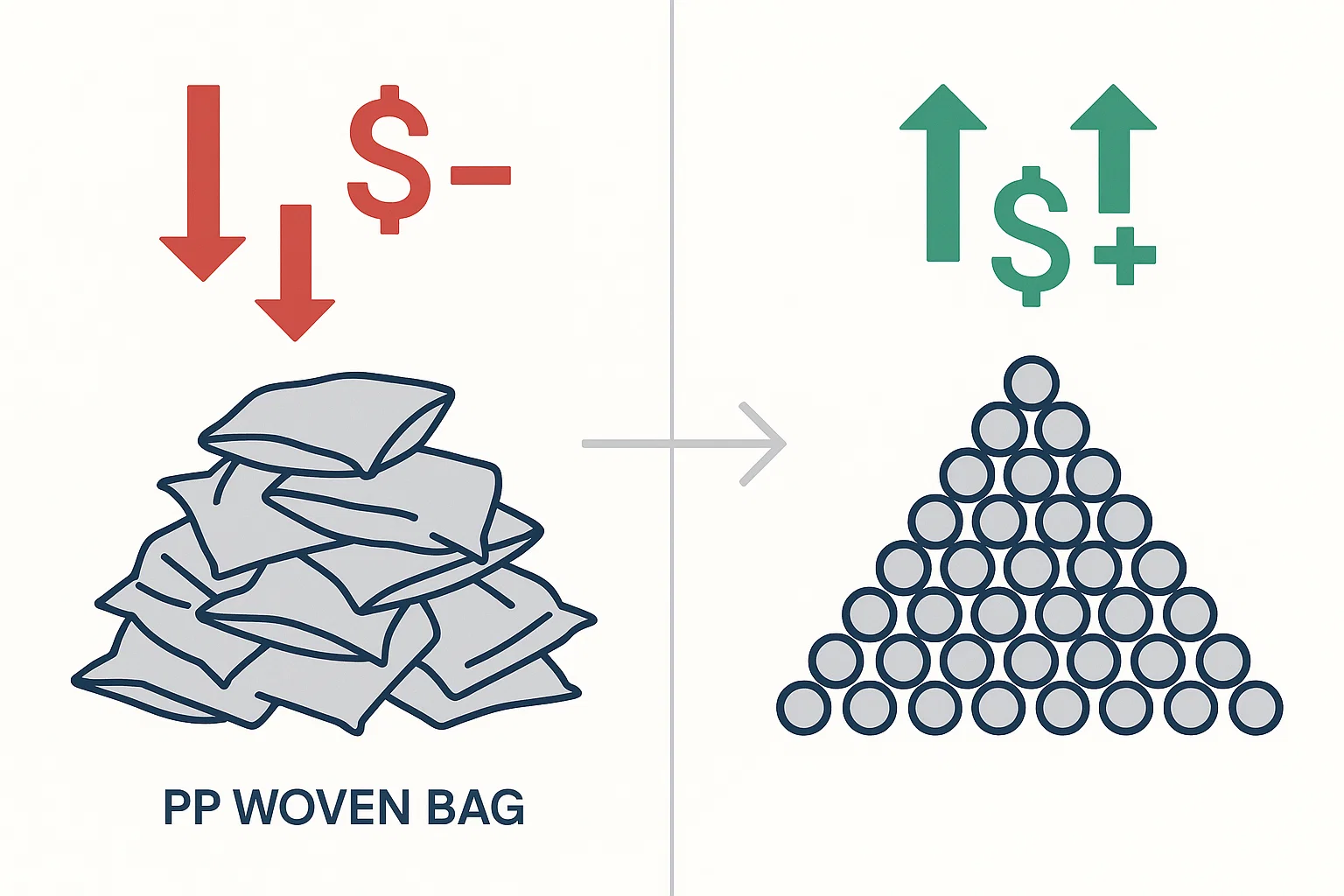

As a business owner or financial decision-maker, every line on your balance sheet matters. The growing pile of PP woven bag and raffia scrap in your facility isn’t just waste—it’s a significant, and often overlooked, cost center. This article makes the business case for transforming that liability into a profitable asset through in-house recycling.

Calculating Your Current Waste Costs

Before exploring the solution, let’s quantify the problem. Your current method of handling post-industrial PP woven scrap likely involves one or more of the following direct and indirect costs:

- Disposal Fees: The direct cost of sending materials to a landfill.

- Transportation & Logistics: The fuel and labor required to move bulky, low-density waste.

- Low Selling Price: If you sell the scrap, you’re likely receiving a low price because it’s in an un-processed, difficult-to-handle form.

- Lost Opportunity Cost: Every ton of scrap you dispose of is a ton of raw material you have to purchase at market price.

Summing these up reveals a substantial, recurring operational expense that directly impacts your profitability.

The Advantages of an In-House Recycling System

By bringing the recycling process in-house with a specialized PP woven bag pelletizing machine, you fundamentally change the financial equation. The benefits are immediate and compounding.

- Drastic Reduction in Raw Material Costs: This is the most significant financial win. The high-quality pellets produced can be directly reintroduced into your manufacturing process, replacing a large portion of expensive virgin PP resin.

- Creation of a New, High-Value Revenue Stream: If you produce more pellets than you can consume internally, you can sell them on the open market at a price significantly higher than what you could get for raw scrap. Densified pellets are a standardized, easy-to-sell commodity.

- Elimination of Disposal & Transport Costs: All costs associated with waste handling and disposal are immediately removed from your operational expenses.

Analyzing the Return on Investment (ROI)

A capital investment in recycling equipment requires a clear ROI analysis. Here are the key factors to build into your calculation:

- Initial Investment (CAPEX): The total cost of the pelletizing line.

- Operational Costs (OPEX): Include energy consumption, labor for one operator, and routine maintenance parts.

- Projected Savings: Calculate the annual cost of the virgin PP resin you will no longer need to purchase.

- Projected Revenue: Estimate the market value of any surplus pellets you plan to sell.

For most manufacturing facilities, the combined savings and new revenue far outweigh the operational costs, leading to a typical payback period of **12 to 24 months**.

Case Study: A Hypothetical FIBC Manufacturer

Consider a factory producing FIBCs (jumbo bags) that generates 50 tons of PP woven scrap per month.

- Without In-House Recycling: They spend money to dispose of the scrap and purchase 100% virgin resin.

- With a Rumtoo Pelletizing Line: They convert the 50 tons of scrap back into high-quality pellets. This not only eliminates their disposal costs but also reduces their monthly virgin resin purchase by 50 tons, resulting in direct savings that can easily exceed tens of thousands of dollars per month.

Frequently Asked Questions for Business Owners

Q1: Beyond the machine price, what are the other major costs to consider?

A: The primary additional costs are installation and shipping. Operationally, you’ll need to account for electricity consumption and labor for one operator per shift. Our team provides a transparent quotation that covers all aspects, so there are no hidden surprises.

Q2: How reliable is the equipment? What about maintenance and downtime?

A: Our machines are built with high-quality, durable components for continuous industrial operation. Routine maintenance is minimal and primarily involves changing screen filters and checking wear parts. We design for reliability to maximize your production uptime and profitability.

Q3: Do we need highly skilled technicians to operate this machine?

A: No. Our pelletizing lines are designed with a user-friendly interface and a high degree of automation. After the initial setup and training provided by our engineers, a general machine operator can competently manage the day-to-day operation of the line.

Q4: How can we be sure of the market value for the recycled pellets?

A: The market for high-quality recycled PP pellets is strong and growing, driven by sustainability initiatives and demand for lower-cost raw materials. The pellets produced by our machines are dense and uniform, making them a desirable commodity. We can provide insights into current market trends to help with your financial modeling.

Wondering what this level of efficiency looks like? Watch a live demonstration of our machine turning waste into a tangible revenue stream.