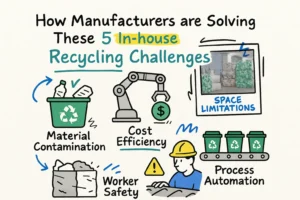

Turn Waste into Profit: How to Overcome the Top 5 In-House Recycling Challenges

In the modern plastics industry, post-industrial waste is no longer just “trash”—it is a valuable asset waiting to be reclaimed. Whether you are dealing with extruder head waste, HDPE pipes, or soft packaging films, implementing an in-house recycling system is one of the smartest moves a manufacturer can make to cut costs and boost sustainability. …