Why a Cutter-Compactor Plastic Pelletizing Machine is Your Ideal Solution for PE/PP Films

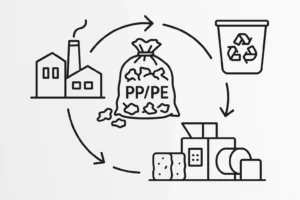

Polyethylene (PE) and Polypropylene (PP) films are ubiquitous in packaging, agriculture, and various industrial applications. From stretch wrap and carrier bags to agricultural films and industrial liners, their lightweight, flexible, and durable nature makes them incredibly useful. However, these same properties present significant challenges when it comes to recycling. As the demand for sustainable practices …