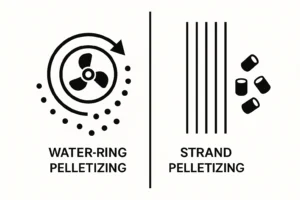

Plastic Pelletizer Price: Water Ring vs. Strand

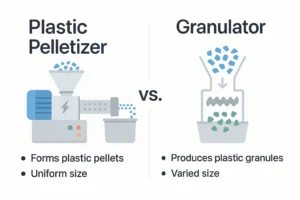

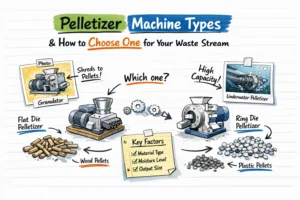

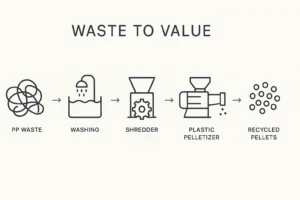

Choosing the right plastic pelletizing system is a major investment. This article provides a detailed cost analysis of water ring versus strand pelletizing technologies, moving beyond the initial price tag to explore the total cost of ownership. We compare upfront investment, operational expenses, maintenance, and material suitability to help industry professionals make an informed financial decision. Gain technical insights and discover which system offers the best ROI for your specific plastic recycling operations.