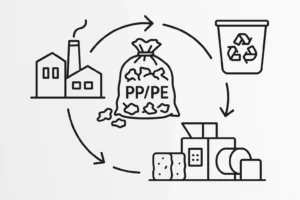

Polypropylene (PP) bags, commonly found in various industries, are known for their durability, lightweight nature, and resistance to moisture. These bags, including woven bags and bulk bags, play a significant role in packaging and transportation. However, as the use of PP bags increases, so does the environmental concern related to their disposal. In this article, we’ll dive deep into how to recycle polypropylene bags effectively, from collection to pelletization, and explore ways to minimize their environmental impact.

What types of plastics can be processed with a pelletizer?

🔧 Comprehensive Guide to Plastic Pelletizing Machines At Rumtoo, we specialize in advanced plastic recycling solutions, offering state-of-the-art pelletizing machines designed to transform plastic waste into valuable raw materials. Our machines cater to a wide array of plastics, ensuring efficient recycling processes for various industries. ♻️ Types of Plastics Suitable for Pelletizing Our pelletizing machines …