Introduction

As manufacturers and industry professionals push for more sustainable operations, recycling multi-layer and composite films has become a critical process. Rumtoo Machine—a leading name in industrial recycling equipment—has developed the Composite Film Pelletizing Machine to efficiently convert complex film wastes into high-quality pellets. This comprehensive guide will help you determine the right pelletizer for your materials, capacity, and quality requirements, ensuring you maximize yield, maintain product consistency, and reduce operational costs.

1. What Are Multi-Layer and Composite Films?

Multi-layer films combine two or more polymer layers—such as PET/PE, PA/PE, or EVOH/PE—to achieve the combined benefits of barrier protection, mechanical strength, and processability. Composite films take this concept further by incorporating metallic foils, paper, or other non-polymeric layers for specialized packaging and industrial applications.

-

Barrier Layers: EVOH or aluminum for oxygen/moisture resistance

-

Structural Layers: PA or PET for rigidity and tensile strength

-

Sealant Layers: PE or PP for heat sealing and printability

These heterogenous constructions present unique processing challenges due to differing melting points, viscosities, and potential contaminants.

2. Key Challenges in Pelletizing Composite Films

-

Thermal Mismatch Layers like EVOH melt around 170 °C while PE requires 200 °C–250 °C. Improper temperature control can lead to under-melting or polymer degradation.

-

Viscosity Differences High-viscosity layers can stagnate in the extruder, creating pressure spikes and die build-up.

-

Non-Polymeric Inclusions Foil, paper, or mineral fillers demand robust filtration to prevent screen and die blockage.

-

Consistent Pellet Quality Uniform pellet size, low fines, and minimal discoloration are vital for repeatable downstream processing.

Rumtoo Machine addresses these challenges through precision screw design, multi-stage filtration, and advanced process controls.

3. Pelletizer Types: Pros, Cons, and Applications

| Type | Advantages | Ideal For |

| — | — | — |

| Single-Screw Pelletizer | Low capital cost; simple maintenance | Homogeneous films; small-to-medium throughput plants |

| Twin-Screw Pelletizer | Excellent mixing; high shear; flexible processing | Multi-layer/composite films; filled compounds |

| Underwater Pelletizer | Precise pellet sizing; minimal dust; high throughput | Large-scale operations needing fine, round pellets |

| Strand Pelletizer | Lower water use; energy-efficient drying | Heat-sensitive or moisture-sensitive polymers |

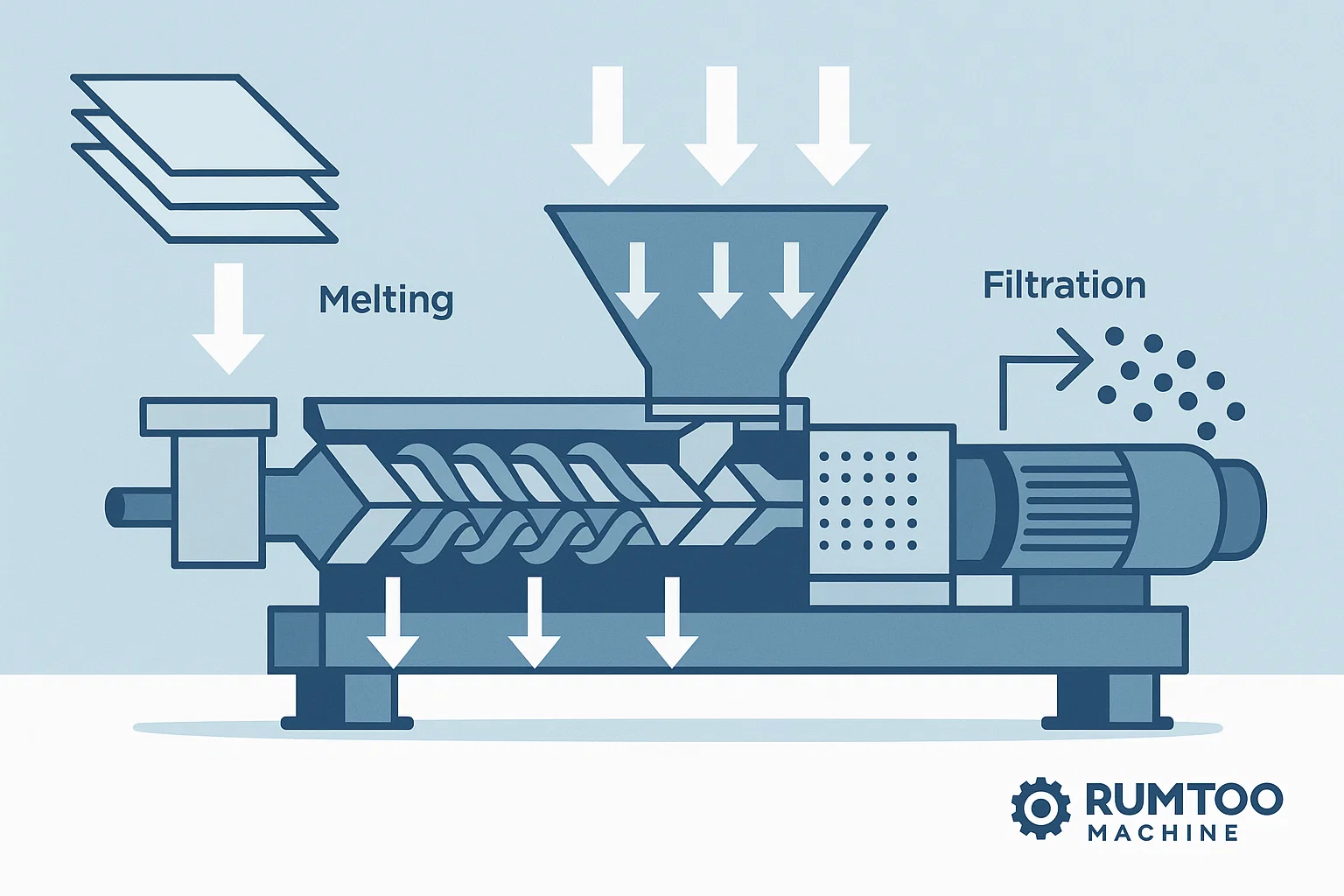

Figure 1: Workflow of Rumtoo Machine Twin-Screw Composite Film Pelletizing System

flowchart TD

A[Film Flake Hopper] --> B[Variable-Pitch Twin Screw]

B --> C[Melting & Mixing Zone]

C --> D[Degassing & Filtration Module]

D --> E[Die Plate Assembly]

E --> F[Underwater Cutting / Strand Cutter]

F --> G[Centrifugal Dryer]

G --> H[Pellet Storage]

4. Why Rumtoo Machine’s Composite Film Pelletizing Machine Stands Out

4.1 Custom Screw Geometry

-

Balanced Conveying and Mixing: Variable-pitch flights ensure gentle melting of barrier layers without shear-induced degradation.

-

Enhanced Dispersive Mixing: Eliminates agglomerates and ensures color and additive uniformity.

4.2 Multi-Stage Filtration System

-

Coarse Screen Changer: Captures metalized foil and large contaminants.

-

Fine Screen Pack: Delivers polymer purity above 99.5% for high-end applications.

4.3 Energy-Efficient Drives

-

Variable-Frequency Motors: Adjust torque and speed for minimal energy draw, even under fluctuating feed conditions.

-

Optimized Heating Zones: Independent temperature control across barrel segments reduces hotspots and power waste.

4.4 Modular Design & Quick-Change Tooling

-

Rapid Die Plate Swaps: Reduce downtime from hours to minutes when switching product specifications.

-

Interchangeable Cutter Heads: From water-ring to strand knives, tailor pellet shape and surface finish.

4.5 Advanced PLC Control & Data Logging

-

Recipe Management: Store and recall process settings for repeatable production runs.

-

Real-Time Monitoring: Track melt pressure, torque, and temperature; alarms for preventive maintenance.

5. Performance Comparison

| Metric | Rumtoo CTP-65 Twin-Screw | Standard Single-Screw | Industry Average |

| — | — | — | — |

| Throughput (kg/h) | 700–1,200 | 300–550 | 400–800 |

| Energy Use (kWh/kg) | 0.16 | 0.22 | 0.18–0.25 |

| Pellet Uniformity (%) | > 98.5 | 95–97 | 96 |

| Screen Change Time (minutes) | 8 | 30 | 20 |

Data based on field trials at multiple recycling facilities.

6. How to Choose the Right Pelletizer

-

Material Composition

- High-barrier or metalized layers? Opt for twin-screw with multi-stage filtration.

-

Required Throughput

-

< 500 kg/h: Single-screw may suffice.

-

500–1,200 kg/h: Twin-screw delivers higher capacity and stability.

-

-

Pellet Specifications

-

Fine, round pellets for injection molding? Underwater pelletizer with water-ring cutter.

-

Larger pellets for extrusion? Strand pelletizer with integrated dryer.

-

-

Energy Efficiency Goals

- Seek drives with variable-frequency controls and insulated barrel jackets.

-

Serviceability

- Look for modular designs with accessible filters, easy-swap cutters, and remote diagnostic capabilities.

7. Application Case Studies

USA – Flexible Packaging Recycler, Ohio

-

Challenge: Recycling PA/PE/EVOH snack films with metalized print layers.

-

Solution: Rumtoo twin-screw extruder equipped with two-stage filtration and an underwater cutter.

-

Outcome: Throughput increased from 450 kg/h to 800 kg/h; energy consumption dropped by 12%; pellet purity > 99.7%.

Europe – Automotive Film Recycling, France

-

Challenge: Composite PET/AL/PE protective films.

-

Solution: Dual-screw CTP-80 with melt-vacuum degassing and strand pelletizing.

-

Outcome: Uniform 3 mm pellets, residual moisture < 0.1%, downstream blow-molding consistency improved by 30%.

8. Frequently Asked Questions

Q1: Can I recycle laminated aluminum-foil films?

A: Yes—by using a twin-screw pelletizer with robust, coarse filtration to remove foil scraps, followed by fine filtration to polish the melt stream.

Q2: What pellet sizes are available?

A: Rumtoo Machine offers pellet diameters from 1.5 mm (underwater) up to 5 mm (strand). Custom cutter heads allow further size and shape variations.

Q3: How often should I replace the screen packs?

A: Under composite film processing, replace coarse screens every 150–200 hours and fine screens every 350–400 hours to maintain throughput and quality.

Q4: Is a standalone dryer necessary?

A: For moisture-sensitive applications, Rumtoo’s integrated centrifugal dryer reduces moisture below 0.2%. For ultra-dry pellets, an auxiliary convection dryer can be added.

Conclusion & Call to Action

Selecting the right Composite Film Pelletizing Machine is vital to unlocking maximum recovery rates, consistent pellet quality, and operational efficiency when recycling multi-layer and composite films. Rumtoo Machine’s decades of experience, coupled with custom-engineered screw profiles, advanced filtration, and energy-efficient drives, ensure your facility meets both production targets and sustainability goals.

Ready to elevate your recycling process?

Contact Rumtoo Machine today or request a personalized quote to discover how our solutions can transform your composite film waste into high-value pellets.