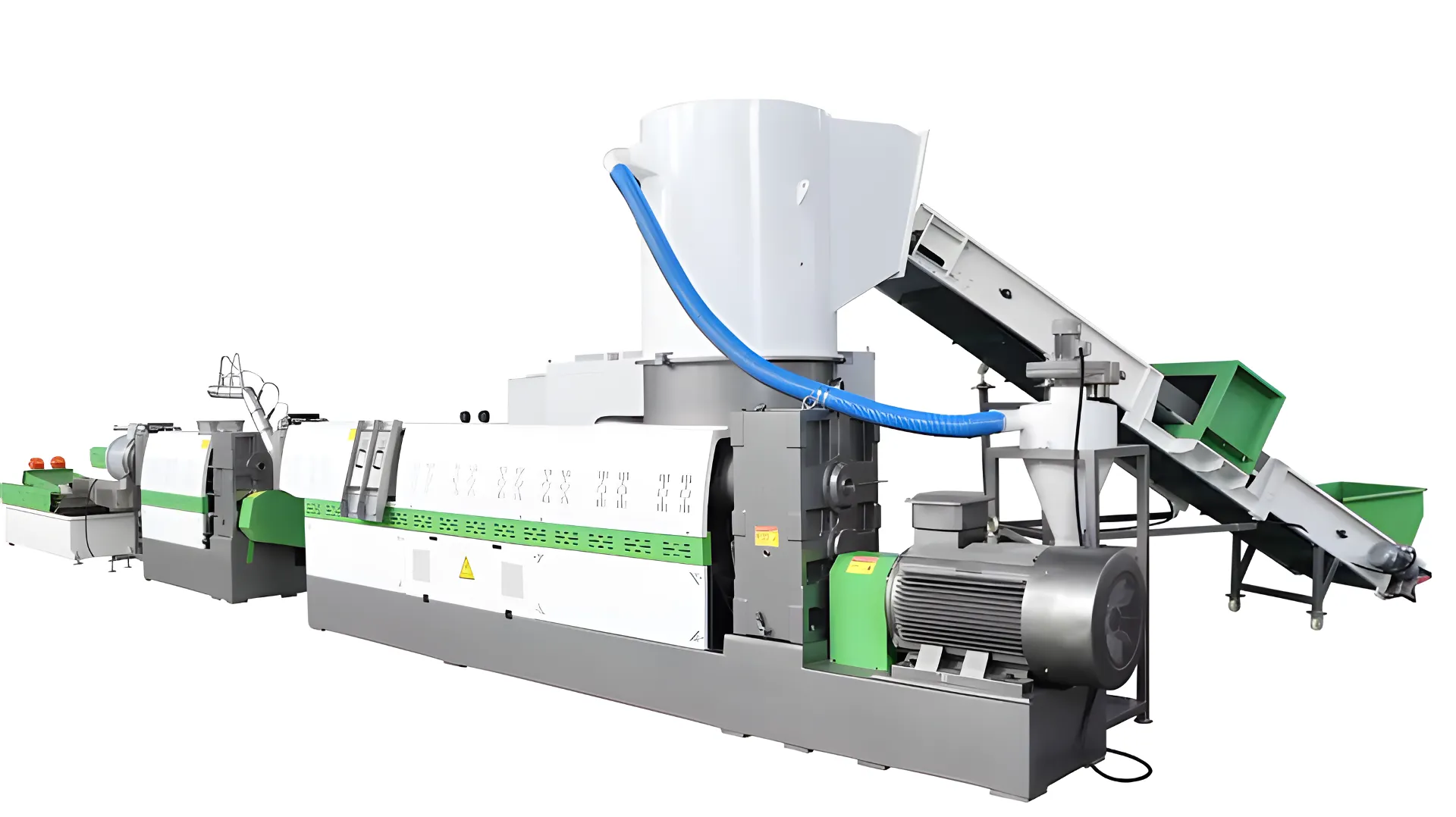

Cutter Compactor Pelletizing Machine

Need a plastic film recycling machine for recycling soft plastic like LDPE/LLDPE/HDPE film, bags, and post-industrial scrap? The Rumtoo ML Series compactor pelletizer densifies loose film in a cutter-compactor, then extrudes, filters, and pelletizes it into uniform, high-value granules.

Request a Custom QuoteWhy Soft Film Can’t Go Straight Into a Normal Extruder

Thin film and bags are “fluffy” and light. In a standard hopper + screw, they don’t feed like rigid flakes. That’s why many film recycling lines suffer from unstable output, overheating, and inconsistent pellet quality.

Bridging (Arching) & Hopper Blocking

Soft film tends to bridge at the hopper throat. Material stops flowing, then suddenly collapses, causing surge feeding and poor melt stability.

Low Bulk Density = “No Bite” on the Screw

Film can slip instead of being conveyed. The screw starves, output drops, and temperature control becomes difficult.

Uneven Melting & More Contamination Risk

When feeding fluctuates, melting and degassing fluctuate. This increases gels, black specks, and odor—especially with printed film.

The “Cutter Compactor + Extruder” Solution

Stable Feeding for Thin Film

The cutter-compactor chops, mixes, and densifies film into a heavy, free-flowing feedstock—then force-feeds it to the extruder. This prevents bridging and keeps output stable.

Cleaner Melt With Vacuum Degassing

Built-in degassing removes moisture, inks, and volatiles. You get cleaner pellets and fewer defects when processing printed film and mixed soft scrap.

Non-Stop Filtration

With a hydraulic screen changer, you can change screens without stopping the line—reducing downtime and protecting pellet quality.

Ideal Applications

Designed for recycling soft plastic, the ML Series cutter compactor pelletizer turns common film waste streams into high-value granules.

Post-Industrial Film

Perfect for clean factory scraps, edge trims, and off-cuts of LDPE, LLDPE, and HDPE stretch films.

Washed Agricultural Film

Handles greenhouse films and mulch films that have been washed and squeezed, tolerating residual moisture.

PP Woven Bags

Efficiently densifies and pelletizes crushed raffia bags, cement bags, and jumbo bags (FIBCs).

Crushed Regrinds

Also suitable for pre-crushed rigid plastics like HDPE bottles, crates, and pipe flakes mixed with films.

Our 4-Step Process

Cutter-Compactor Densifying

Film is conveyed into the cutter-compactor, where it is cut, mixed, and densified into a stable, free-flowing feedstock for extrusion.

Extrusion & Degassing

The densified material is forced into the single-screw extruder, then melted, plasticized, and vacuum degassed.

Filtration & Pelletizing

Molten plastic is filtered for impurities and then cut into uniform pellets by a water-ring pelletizing system.

Drying & Collection

Pellets are rapidly dewatered and sent to a silo for cooling, bagging, and storage.

See the Cutter Compactor Pelletizer in Action

From tangled film to uniform pellets. Watch how cutter-compactor densifying solves “film feeding” problems and keeps output stable.

Technical Specifications

| Model | Compactor | Single Screw Extruder | Capacity (kg/h) | |||

|---|---|---|---|---|---|---|

| Effective Volume (L) | Motor Power (KW) | Screw Diameter (mm) | L/D Ratio | Motor Power (KW) | ||

| ML85-100 | 300 | 37-45 |

85

100

|

28-33:1

10:1

|

55-75 | 150-200 |

| ML100-120 | 500 | 55-75 |

100

120

|

28-33:1

10:1

|

90-110 | 250-350 |

| ML130-150 | 800 | 90-110 |

130

150

|

28-33:1

10-12:1

|

132-160 | 400-550 |

| ML150-160 | 950 | 110-132 |

150

160

|

28-33:1

12:1

|

185-200 | 500-650 |

| ML160-180 | 1100 | 110-132 |

160

180

|

28-33:1

12:1

|

220-250 | 700-900 |

| ML180-200 | 1100 | 160-185 |

180

200

|

28-33:1

12:1

|

280-315 | 900-1200 |

* Specifications subject to change without notice.

Equipment Gallery

“We were constantly fighting hopper bridging and unstable output with thin film. After switching to a cutter-compactor feeding pelletizer, feeding became stable and the pellet quality improved noticeably.”

Warranty & Installation

1-Year Limited Warranty

Each of our recycling machines includes a comprehensive one-year limited warranty, giving you peace of mind with your investment.

Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Get Your Custom Solution & Quote

Our experts will analyze your material and production needs to provide a tailored solution and a competitive quote within 24 hours.