The agricultural industry feeds the world, and in modern farming, plastic film is an indispensable tool. From mulch films that conserve water and suppress weeds to greenhouse covers that extend growing seasons, these plastics have revolutionized crop yields. But this progress comes with a significant environmental challenge: what happens to millions of tons of agricultural film at the end of its life?

Often laden with dirt, sand, moisture, and organic residue, this material has long been considered one of the most difficult waste streams to recycle. For many, the only options have been landfilling or burning, both with severe environmental consequences.

The good news? It doesn’t have to be this way.

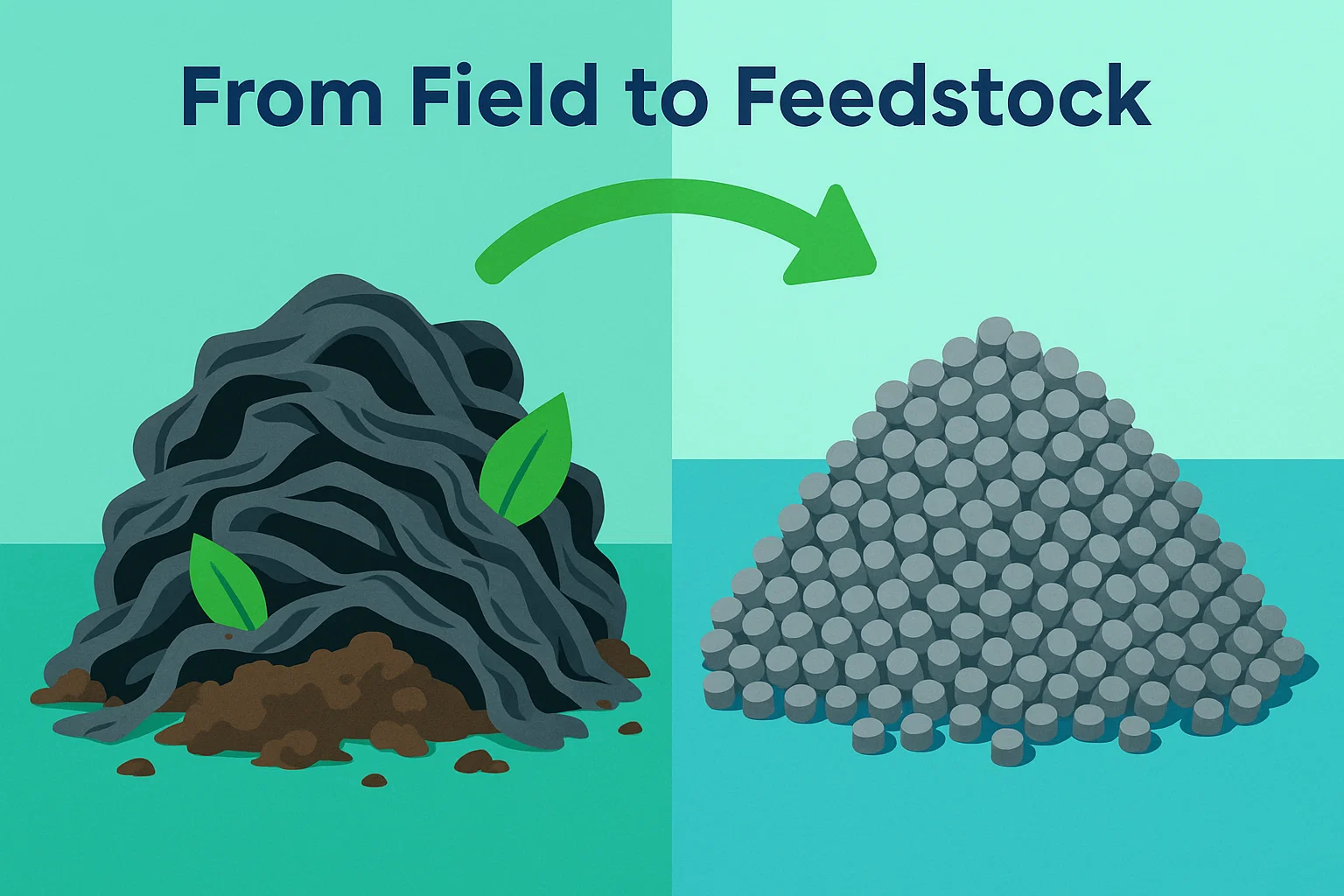

With the right technology and a systematic approach, heavily contaminated agricultural film can be transformed from a costly waste problem into a high-value, reusable feedstock. This guide provides a comprehensive overview of the process, showcasing how Rumtoo’s integrated washing and pelletizing solutions are engineered to conquer the toughest challenges in plastics recycling.

Chapter 1: Understanding the Unique Challenges

Before diving into the solution, it’s crucial to understand why agricultural film is notoriously difficult to process. Unlike relatively clean post-industrial scrap, post-consumer agricultural film presents several hurdles:

- Extreme Contamination: The primary challenge. Bales of used mulch film can contain up to 70% non-plastic material by weight, including soil, sand, rocks, and plant matter. These abrasive contaminants can wreak havoc on standard recycling machinery.

- High Moisture Content: Film collected from the field is almost always wet, which interferes with shredding and extrusion if not properly managed.

- Residual Contaminants: Trace amounts of pesticides and fertilizers may be present and must be thoroughly washed away to ensure the final product is safe for reuse.

- Material Inconsistency: The film itself can be a mix of LDPE, LLDPE, and EVA, often in very thin gauges, making it light, fluffy, and difficult to handle after washing.

Attempting to process this material with standard equipment will inevitably lead to machine damage, poor product quality, and operational failure. A specialized, robust, and fully integrated system is essential.

Chapter 2: The Rumtoo Solution: An Integrated Washing & Pelletizing Line

At Rumtoo, we have engineered our systems from the ground up to tackle these specific problems. A complete line turns dirty, baled film into clean, uniform pellets in a continuous, automated process. Here’s a step-by-step walkthrough.

Step 1: Debaling & Heavy-Duty Shredding

The process begins with breaking open the compressed bales and feeding the film into a heavy-duty, single-shaft shredder. Unlike granulators, Rumtoo shredders are designed with high-torque, low-speed operation to handle rocks and other hard contaminants without catastrophic failure, breaking the film down into a uniform, manageable size for the washing process.

Step 2: The Washing Core – Friction and Separation

This is where the magic happens. The shredded film enters a multi-stage washing and separation system:

- Floating-Sinking Tank: The film mixture is submerged in water. The lighter plastic film (PE/LDPE) floats, while heavier contaminants like sand, soil, and rocks sink to the bottom and are removed by a screw conveyor.

- High-Friction Washer: This is the workhorse of the cleaning process. A high-speed rotor inside a cylindrical screen chamber creates intense friction, scrubbing the film surfaces against each other to dislodge the most stubborn dirt and grime. This mechanical action is far more effective than a simple rinse.

Step 3: Dewatering and Thermal Drying

After a final rinsing stage, the clean film flakes are saturated with water. To prepare them for extrusion, we employ a two-stage drying process:

- Mechanical Dewatering: A screw press or centrifugal dewatering machine mechanically squeezes a significant portion of the water out, quickly reducing moisture content from over 80% down to around 15-20%.

- Thermal Drying System: The dewatered flakes are then conveyed through a hot air drying pipeline. This crucial step evaporates the remaining moisture, bringing the final content below 5%—the critical threshold for high-quality pelletizing.

Step 4: The Final Transformation – The Rumtoo Cutter Compactor Pelletizer

This is the heart of the system. The clean, dry film flakes are fed into a Rumtoo Cutter Compactor Pelletizing Machine. This integrated unit performs three functions in one:

- Cutting & Densifying: Rotating blades cut and heat the fluffy film through friction, densifying it into a hot, semi-molten state.

- Forced Feeding: This densified material is then directly and consistently forced into the extruder screw. This unique design eliminates the inconsistent feeding problems common with fluffy materials and removes the need for a separate agglomerator.

- Extrusion & Degassing: The material is fully melted, homogenized, and passed through a vacuum degassing zone to remove any remaining volatiles, ensuring a smooth, bubble-free final product.

Step 5: Advanced Melt Filtration & Pelletizing

The molten plastic is passed through a high-capacity melt filter to remove any final, minute impurities before flowing to a water-ring pelletizing head, which cuts the plastic into clean, uniform, and commercially valuable pellets.

Chapter 3: The Result: From Worthless Waste to Valuable Resource

The output of a Rumtoo integrated line is not just recycled plastic; it is a high-quality, consistent raw material ready to be sold back into the manufacturing industry. These pellets are used to produce a wide range of new products, including:

- Construction pipes and drainage systems

- Durable outdoor furniture

- Industrial pallets and crates

- Garbage bags and new film applications

By investing in the right technology, recyclers can turn a low-cost, abundant, and challenging waste stream into a highly profitable and environmentally positive business venture.

Your Partner in Tackling the Toughest Plastics

Recycling contaminated agricultural film is not a simple task, but the challenges are far from insurmountable. It requires a deep understanding of the material and a system engineered for its specific properties.

The challenges of agricultural film are unique, and so are our solutions. Contact a Rumtoo engineer today to discuss your specific project, and let us design a system that turns your waste problem into a revenue stream.