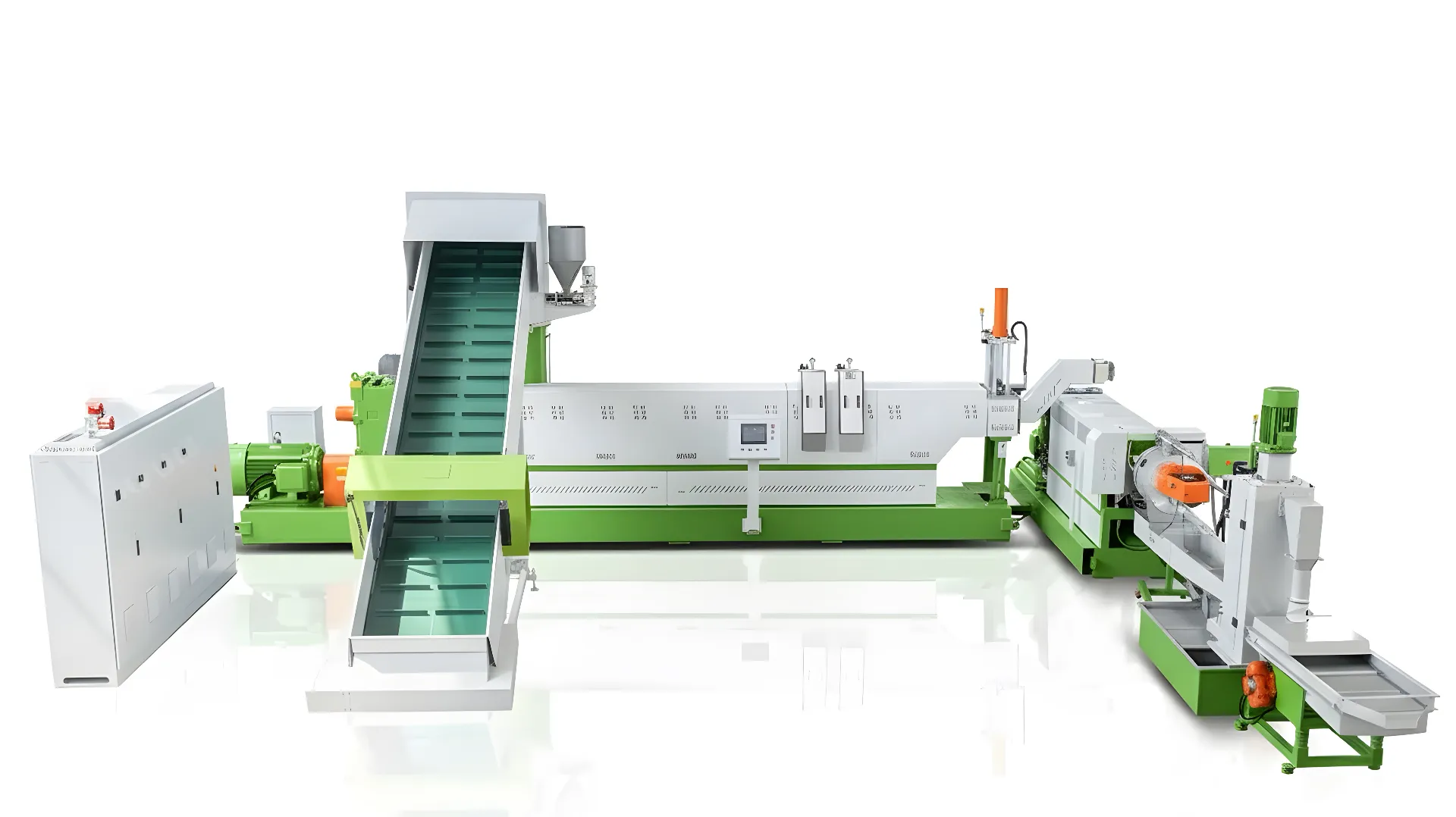

Heavy Printed Film Granulating Line

Rumtoo Machinery specializes in R&D and production of granulating lines for heavily printed films. Our high-quality system efficiently removes inks and moisture, converting challenging waste into valuable, high-grade pellets.

Get a Quote for Your Material

Why Choose Our Granulating Line?

Our system is engineered for maximum efficiency, reliability, and automation, providing a superior return on your investment.

High Efficiency

Compared to primary designs, the output of our second-generation film granulator is increased by 20%.

Low Power Consumption

We’ve reduced power consumption by 15%, lowering your operational costs and improving sustainability.

Highly Automated

The entire granulating line can be managed by only two operators, maximizing productivity and minimizing labor costs.

See It In Action

Watch our Heavy Printed Film Granulating Line transform raw film scrap into high-quality, uniform pellets.

Versatile Application Range

Our machine is designed to handle a wide variety of plastic materials, shapes, and types, making it a flexible solution for your recycling needs.

Applicable Plastic Materials

- PE, HDPE, LDPE

- PP, BOPP

- PET, PA, EPE, and more

Material Shapes

- Film (rolls, loose, bundled)

- Bags (woven and non-woven)

- Crushed materials (PE, PP)

Key Components & Technology

Discover the advanced components that make our granulating line the ideal choice for processing heavily printed films.

Compactor / Agglomerator

Crushes, dries, and compacts material for a fast, stable feed. Frictional heating pre-conditions the film, improving efficiency and preparing it for extrusion.

Specialized Extruder

Features a double-zone vacuum degassing system, crucial for removing volatiles from inks and moisture, ensuring pure, high-quality pellets.

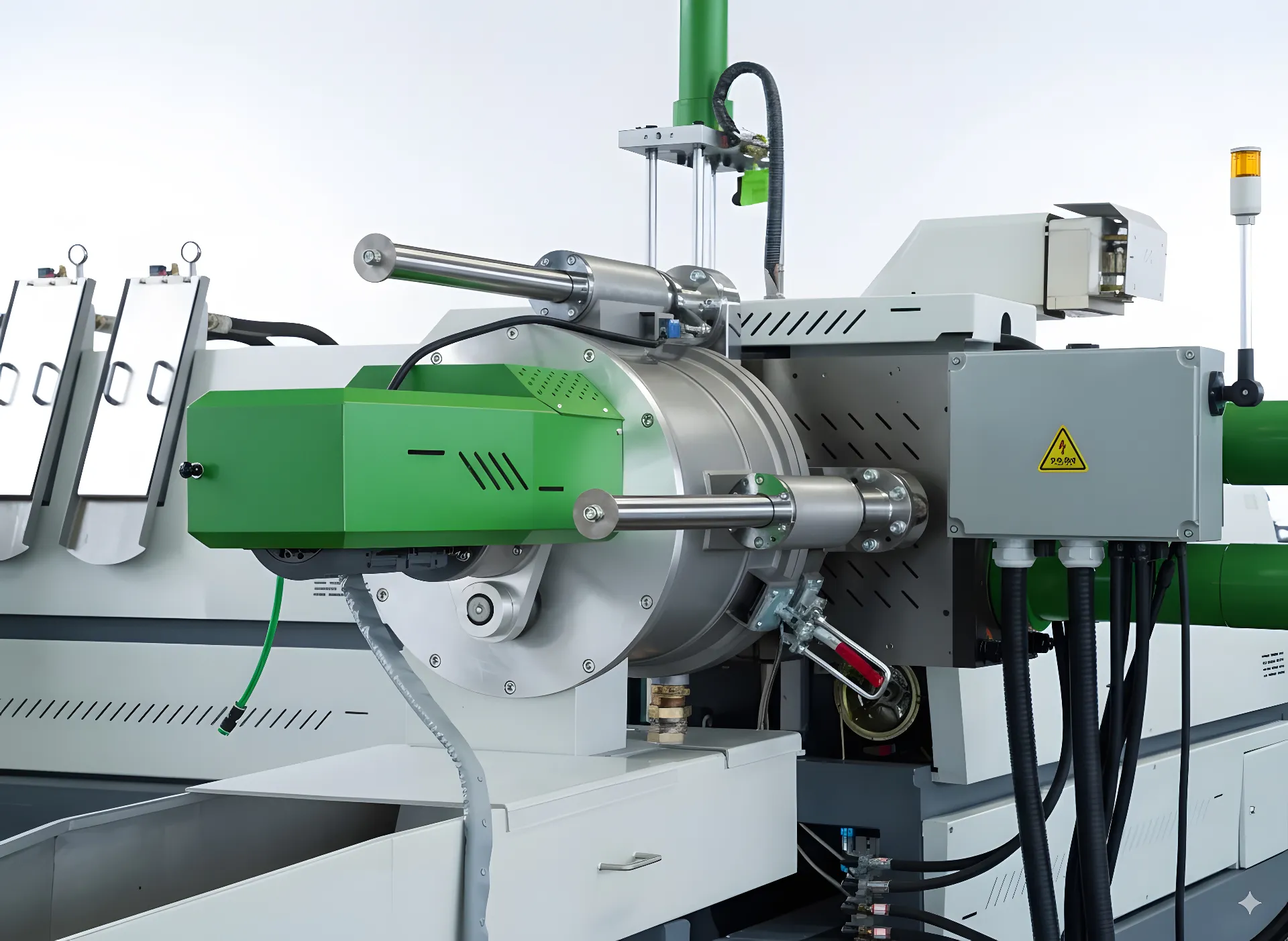

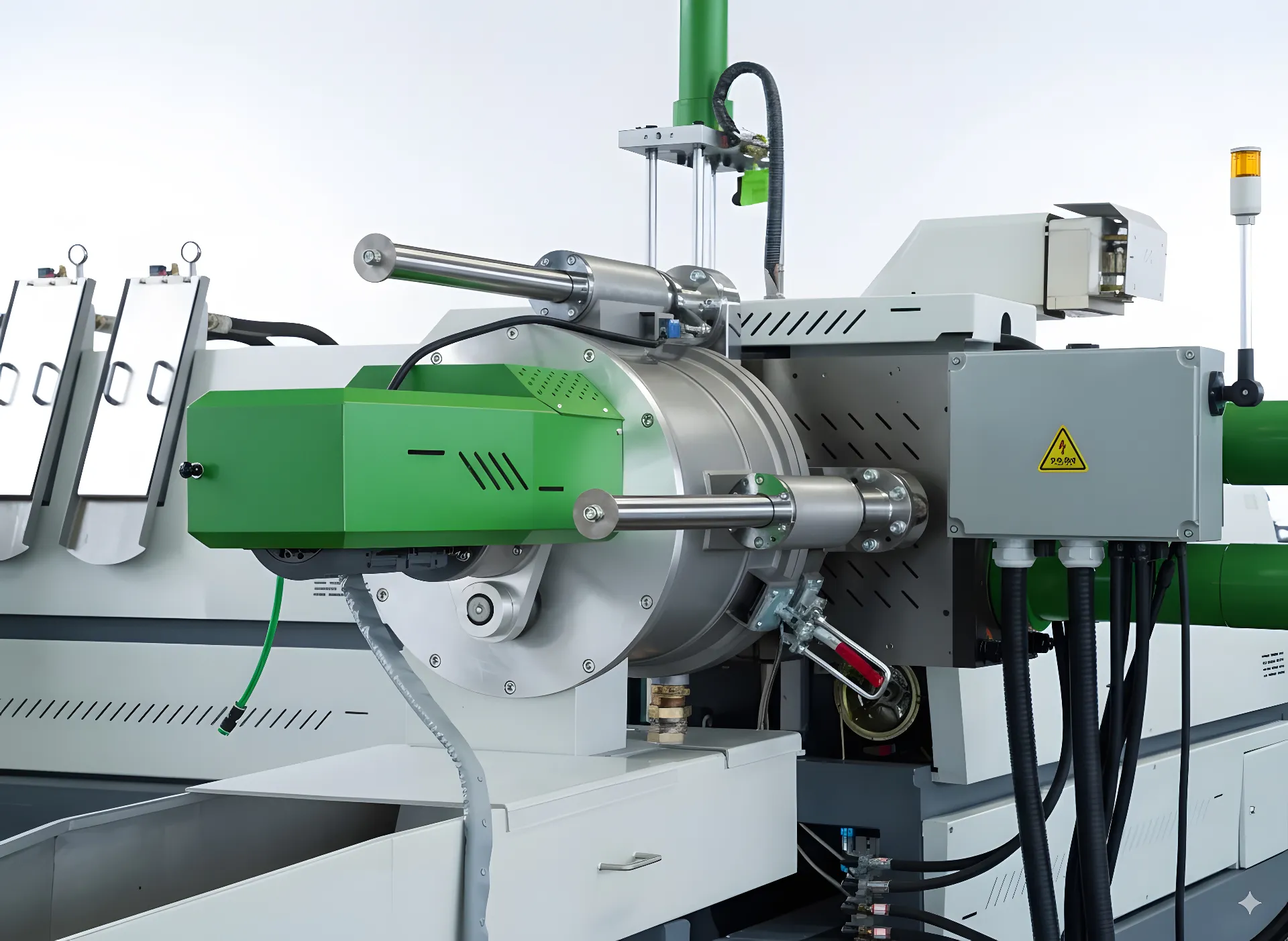

Water-Ring Die-Face Cutting

Automated, high-precision cutting system produces uniform pellets. The blade speed adjusts to melt pressure, ensuring consistency.

Technical Parameters

| Model | ML85 | ML100 | ML130 | ML160 | ML180 |

|---|---|---|---|---|---|

| Output (kg/h) | 180~250 | 300~400 | 500~600 | 700~800 | 1000~1500 |

Final Product & Shipping

We produce high-quality pellets and ensure your machine is packaged securely for global shipping.

Request Your Custom Solution

Tell us about your material and production needs. Our experts will provide a tailored solution and a competitive quote within 24 hours.