Unlocking the Value in Plastic Waste: The Core Function of a Pelletizer

In the world of industrial recycling, transforming bulky, low-value plastic waste into uniform, high-value raw material is the ultimate goal. At the heart of this transformation lies a critical piece of machinery: the plastic pelletizer. For recycling professionals and facility managers, understanding the intricate workings of this equipment is not just a matter of technical curiosity—it’s fundamental to optimizing operations, ensuring end-product quality, and maximizing profitability.

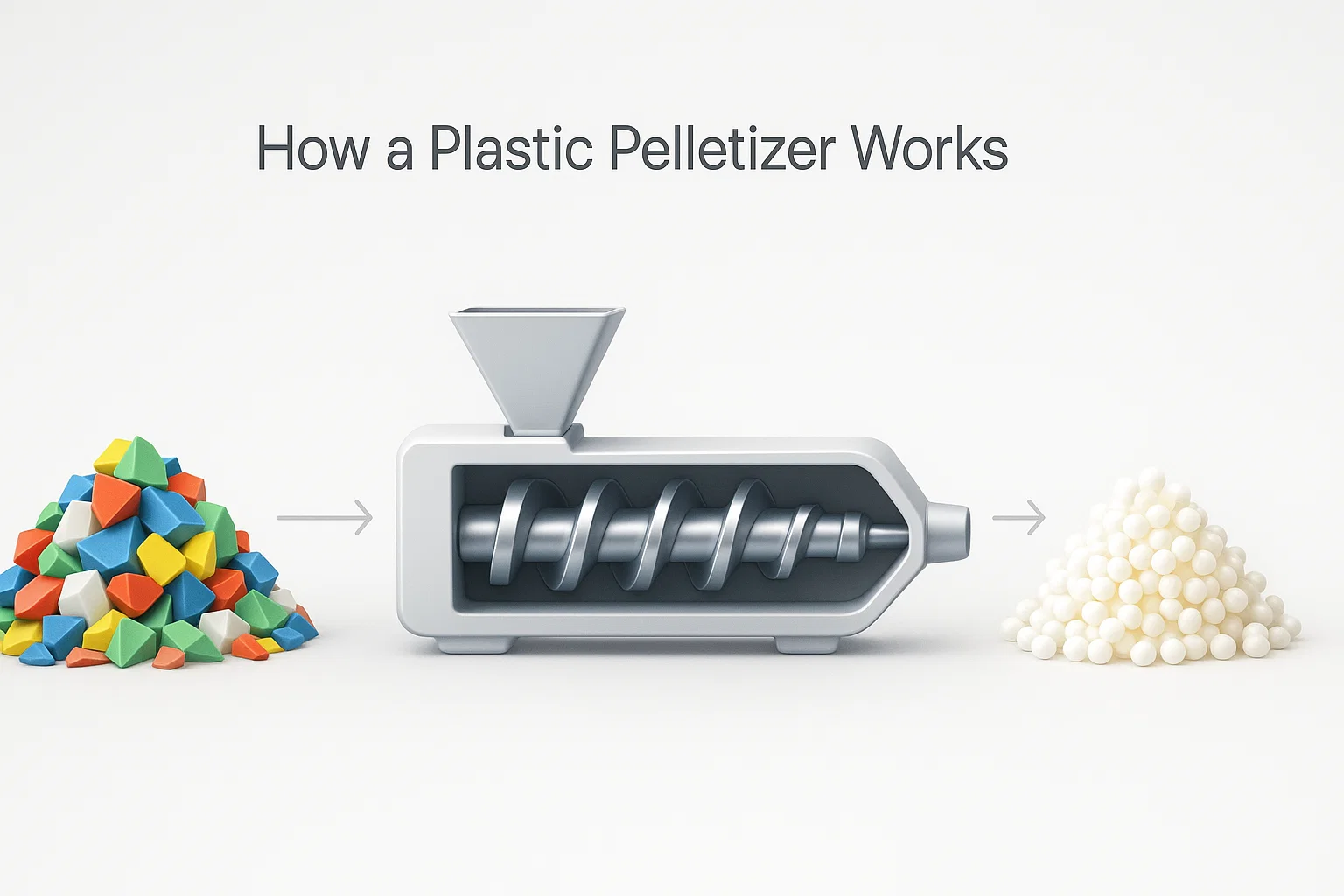

A plastic pelletizer, or pelletizing line, is an integrated system designed to melt, filter, and cut cleaned plastic waste into small, consistent granules known as pellets or nurdles. These pellets are the lifeblood of the circular economy, ready to be sold and used in the manufacturing of new products.

At Rumtoo, we believe an informed buyer is a successful partner. This guide will walk you through the entire pelletizing process, from raw material intake to the final, saleable pellet.

The Anatomy of a Plastic Pelletizing Line: Key Components

Before diving into the process, it’s essential to understand the main components that work in concert. A complete pelletizing line is more than just one machine; it’s a symphony of integrated modules.

-

Feeding System: Introduces the raw, cleaned plastic scrap (flakes or film) into the system at a controlled rate.

-

Extruder: The powerhouse of the line. It consists of a heated barrel containing one or two rotating screws. Its job is to melt, mix, and build pressure.

-

Melt Filtration System: A screen changer that removes any remaining solid contaminants (like metal, paper, or other plastics) from the molten polymer.

-

Degassing (Venting) Zone: Vents in the extruder barrel that allow trapped moisture and volatile gases to escape, which is crucial for producing high-quality, void-free pellets.

-

Pelletizing Head (Die): A specialized plate with numerous small holes through which the molten plastic is forced, forming spaghetti-like strands or “noodles.”

-

Cutting System: The unit that cuts the plastic strands into uniform pellets. The type of cutting system is a major differentiator between pelletizer models.

-

Cooling and Transport System: A system, typically using water or air, to rapidly cool and solidify the freshly cut pellets.

-

Drying and Storage: A dewatering machine or centrifugal dryer removes residual moisture before the pellets are conveyed to a storage silo, ready for bagging.

The Step-by-Step Pelletizing Process: From Flake to Pellet

Understanding the sequence of operations helps clarify how a plastic pelletizer achieves its remarkable transformation.

Step 1: Material Feeding and Conveying

The process begins with prepared plastic waste—typically washed and crushed into small flakes. A screw conveyor or belt feeder transports this material from a hopper into the extruder. Consistent, uniform feeding is critical to prevent process fluctuations and ensure a stable output.

Step 2: Melting, Mixing, and Homogenization (The Extrusion Stage)

Once inside the extruder’s barrel, the plastic flakes are propelled forward by a large, rotating screw (or twin screws). This stage accomplishes three things simultaneously:

-

Conveying: The material moves from the feed throat toward the die.

-

Melting: A combination of friction from the screw’s rotation and external heating elements along the barrel melts the plastic into a viscous, molten state.

-

Mixing & Homogenizing: The screw’s design thoroughly mixes the molten polymer, ensuring a consistent temperature and viscosity throughout. Any colorants or additives are blended in at this stage.

Step 3: Filtration and Degassing

As the homogenized melt approaches the end of the extruder, it is forced through a high-pressure melt filtration system. This screen changer traps physical impurities, ensuring the final product is pure.

Simultaneously, specially designed vacuum-assisted vents along the barrel extract any trapped air, moisture, and volatile organic compounds (VOCs). Effective degassing is vital for preventing porous, brittle pellets and is especially important when processing printed films or slightly wet materials.

Step 4: Pellet Formation and Cutting

This is where the magic happens. The clean, pressurized molten plastic is extruded through the die head, forming continuous strands. These strands are then immediately cut into pellets. The method of cutting defines the type of pelletizing system.

Chart: Comparison of Pelletizing Systems

For industrial buyers, choosing the right cutting technology is a critical decision based on the material type, throughput needs, and operational preferences.

| Feature | Strand Pelletizing (Cold Cut) | Water-Ring Pelletizing (Hot Die Face) | Underwater Pelletizing (Hot Die Face) |

| — | — | — | — |

| Process | Strands are cooled in a water bath, then cut by a rotor. | Blades rotate on the die face, cutting pellets which are flung into a water ring. | Blades cut pellets on the die face completely submerged in a water chamber. |

| Suitable Materials | Most thermoplastics (PE, PP, PS). Ideal for filled or reinforced plastics. | Polyolefins (PE, PP), Styrenics. Excellent for materials with lower MFI. | A wide range of polymers including PET, PA, TPU, and materials sensitive to oxidation. |

| Pellet Shape | Cylindrical | Spherical / Lentil-shaped | Spherical / Uniformly shaped |

| Operational Cost | Lower initial investment and maintenance. | Moderate initial cost. Efficient operation. | Higher initial investment and complexity. |

| Automation & Labor | More labor-intensive (strand startup). | Highly automated. | Fully automated, continuous process. |

| Rumtoo Insight | A robust and versatile choice for many standard recycling applications. | The most popular method for high-volume polyolefin recycling due to its efficiency. | The premium choice for high-quality, perfectly uniform pellets and difficult materials. |

Choosing the Right Plastic Pelletizer for Your Operation

The ideal plastic pelletizer depends entirely on your specific needs. Consider these factors:

-

Plastic Type: Are you processing rigid plastics (HDPE, PP) or soft films (LDPE, LLDPE)? The material’s melt flow index (MFI) and characteristics dictate the best extruder and cutting design.

-

Contamination Level: The nature and amount of contamination will determine the sophistication of the filtration and washing systems required upstream.

-

Throughput Requirements: Your desired output in kg/hr or tons/day is a primary factor in sizing the entire line.

-

Operational Footprint: Space limitations can influence the choice between a compact water-ring system and a longer strand pelletizing line.

For operations focusing on soft plastics like PE films and agricultural films, a machine specifically designed for this input is crucial. For instance, if you primarily handle such materials, a system like our Soft Plastic Single Screw Pelletizing Machine is engineered with an agglomerator/compactor to densify the light material before it enters the extruder, ensuring stable feeding and high output.

Frequently Asked Questions (FAQ)

1. What is the main difference between a single-screw and a twin-screw extruder in a pelletizer?

A single-screw extruder is a robust, cost-effective workhorse ideal for reprocessing homogenous, pre-cleaned thermoplastic waste. A twin-screw extruder offers superior mixing, compounding, and degassing capabilities, making it better for blending different polymers, incorporating high levels of additives, or processing materials that are difficult to melt or require intensive venting.

2. How much maintenance does a plastic pelletizer require?

Routine maintenance is key to longevity and performance. This includes daily checks of lubrication and heating elements, regular changing of filter screens, and periodic inspection and replacement of high-wear parts like screws, barrels, and cutting blades. Rumtoo provides detailed maintenance schedules and support for all our machinery.

3. Can one pelletizer handle all types of plastic?

While some pelletizers are versatile, no single machine is optimized for all plastic types. A machine designed for PET will have different screw geometry and drying requirements than one for soft PE film. It’s crucial to select a pelletizer optimized for your primary feedstock to ensure maximum efficiency and pellet quality.

4. What is the typical ROI on a plastic pelletizing line?

The return on investment (ROI) depends on factors like the cost of your plastic waste feedstock, the market price for recycled pellets, your operational costs (labor, energy), and the machine’s throughput. With a reliable, efficient machine from a trusted supplier like Rumtoo, many of our clients see a strong ROI within 18-36 months.

5. How does Rumtoo support customers after the sale?

Our commitment extends beyond the purchase. Rumtoo provides comprehensive support including installation supervision, operator training, a reliable supply of spare parts, and remote technical assistance to ensure your plastic pelletizer operates at peak performance for years to come.

Conclusion: Your Partner in Advanced Recycling

A plastic pelletizer is more than a machine; it’s the engine of your recycling operation. By converting challenging waste streams into a valuable commodity, it closes the loop on plastic production. Understanding its mechanics—from the powerful extrusion process to the precision of the cutting system—empowers you to make a strategic investment that will pay dividends in quality, efficiency, and profitability.

Ready to explore the right pelletizing solution for your facility? The expert team at Rumtoo is here to help you navigate the options and engineer a system tailored to your unique needs.

Contact us today to discuss your project or browse our full range of advanced plastic recycling machinery.