Recycling expanded polystyrene (EPS) foam presents a unique set of challenges and opportunities, especially for manufacturers and industrial recyclers. With increasing environmental pressure and the demand for sustainable operations, selecting the right EPS foam recycling equipment is more critical than ever. At Rumtoo Machine, we understand the complexities of foam waste management and provide tailored machinery solutions to meet specific industrial needs.

In this article, we’ll guide you through the key considerations when choosing EPS foam recycling equipment, highlight popular machine types, and help you identify the best fit for your operational goals.

Understanding EPS Foam and Why It Needs Specialised Recycling

EPS foam, commonly used in packaging and insulation, is lightweight yet bulky—making it difficult and expensive to transport without compression. Traditional recycling systems often fall short when handling EPS due to its low density and high air content. That’s where EPS foam recycling equipment from Rumtoo Machine proves essential, offering efficient size reduction and densification.

Key Factors to Consider When Choosing EPS Foam Recycling Equipment

1. Volume and Type of EPS Waste

Evaluate how much foam you generate and its characteristics (e.g., clean packaging vs. contaminated industrial waste). High-output facilities require equipment that can handle large volumes efficiently.

2. Available Space and Infrastructure

Some machines, like cold press compactors, have a smaller footprint, while others, such as hot melting systems, may need more floor space and ventilation. Rumtoo Machine offers scalable solutions for all factory sizes.

3. Desired End Product

Do you need compacted blocks for resale, or are you aiming to produce melt-processed ingots for pelletisation? The choice between cold press and hot melt systems depends on your downstream goals.

4. Energy Efficiency and Environmental Compliance

Consider your energy consumption targets and emissions standards. Rumtoo’s advanced machines are built with energy efficiency in mind, ensuring compliance with both local and global regulations.

Common Types of EPS Foam Recycling Equipment

| Equipment Type | Description | Ideal For |

|---|---|---|

| Cold Press Machine | Compresses EPS without heating, forming blocks. | Small to medium-volume operations. |

| Hot Melting Machine | Melts EPS into dense ingots. | High-volume facilities. |

| Crusher + Densifier | Breaks down foam before compaction. | Contaminated or mixed EPS sources. |

Learn more about our EPS Foam Cold Press Machine

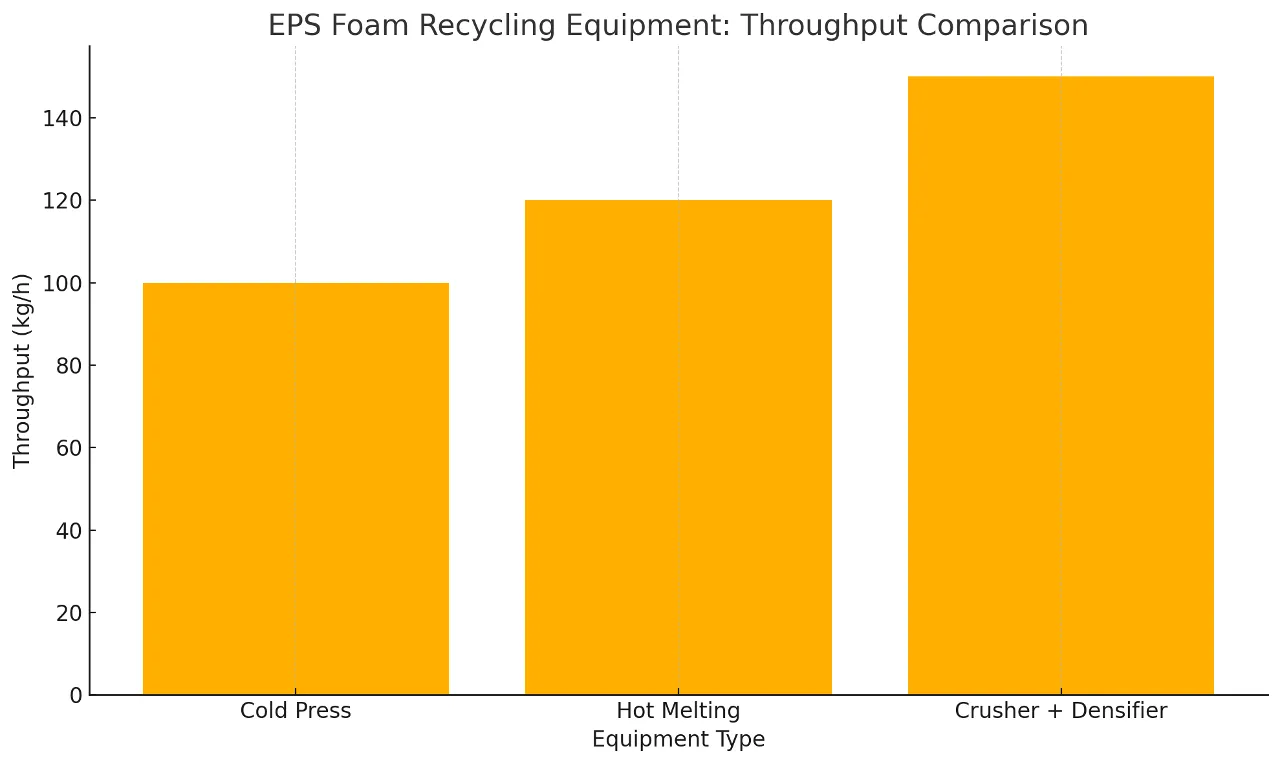

Performance Comparison of EPS Recycling Equipment

To help you visualise the differences, here’s a comparative look at typical performance indicators across various machine types:

As seen, crusher + densifier systems tend to offer the highest throughput but also consume more energy. Cold press machines strike a balance between operational simplicity and cost-effectiveness, making them a popular choice for manufacturers looking for a practical start to their recycling journey.

Why Choose Rumtoo Machine?

At Rumtoo Machine, we bring decades of expertise in designing, manufacturing, and servicing high-performance EPS foam recycling equipment. Our engineers work closely with clients to customise solutions that meet exact requirements, whether it’s reducing transportation costs or maximising foam reuse in production cycles.

Our machinery is:

- Built with premium-grade components

- CE-certified for safety and efficiency

- Supported by a global after-sales service team

Frequently Asked Questions (FAQ)

Q1: Can Rumtoo machines handle contaminated EPS foam?

Yes, certain models like the crusher + densifier are designed to process mixed or dirty EPS efficiently.

Q2: What’s the typical ROI on an EPS foam recycling machine?

Most clients recover their investment within 12–24 months, depending on usage volume and resale of compacted foam.

Q3: Do I need special training to operate the machine?

Our systems are user-friendly and include full training and documentation. Remote support is also available.

Q4: How do I know which model is right for my factory?

Contact us for a needs assessment. We’ll recommend a machine based on your EPS volume, facility layout, and budget.

Ready to Take the Next Step?

Let Rumtoo Machine help you turn waste into value. Our expert team is here to guide you in choosing the most effective EPS foam recycling solution for your operations.

👉 Contact us today to request a quote or book a free consultation.