Mini Lab

Twin Screw Extruder

Empowering polymer innovation with precision, flexibility, and data-driven control for R&D, material testing, and small-batch production.

Request ConsultationWhy Choose Our Mini Lab Extruder?

Compact & Desktop-Ready

With an ultra-compact and exquisite design, this extruder fits on a standard lab bench, saving valuable laboratory space.

Precision PLC Control

Intuitive PLC touch-screen offers high-precision control and real-time data monitoring, easily linked to a PC for analysis.

Advanced R&D Capabilities

Perfect for developing new polymer formulations, studying blending modifications, and conducting advanced material research.

Micro-Scale Production

Ideal for creating small, precise batches with a minimum output of ~100g, minimizing material waste in experimental phases.

Versatile Material Formulation

Process a wide range of materials, from thermoplastics and biodegradable masterbatches to high-fill compounds and color masterbatches.

Ideal for Education & Training

Its safe, user-friendly, and transparent process makes it an excellent tool for university labs and teaching chemical engineering principles.

Operational Workflow

Material Dosing

Precisely feed polymer pellets, powders, and additives into the hopper.

Melting & Mixing

Intermeshing twin screws convey, melt, and homogenously mix materials.

Venting & Degassing

Remove volatiles and moisture through the vent port to ensure material purity.

Extrusion & Forming

Molten polymer is pushed through a custom die to form strands or profiles.

Cooling & Pelletizing

Extruded strands are cooled and cut into uniform pellets for analysis or use.

See the Extruder in Action

Watch the seamless process from raw material feeding to final pellet production on our Mini Lab Extruder.

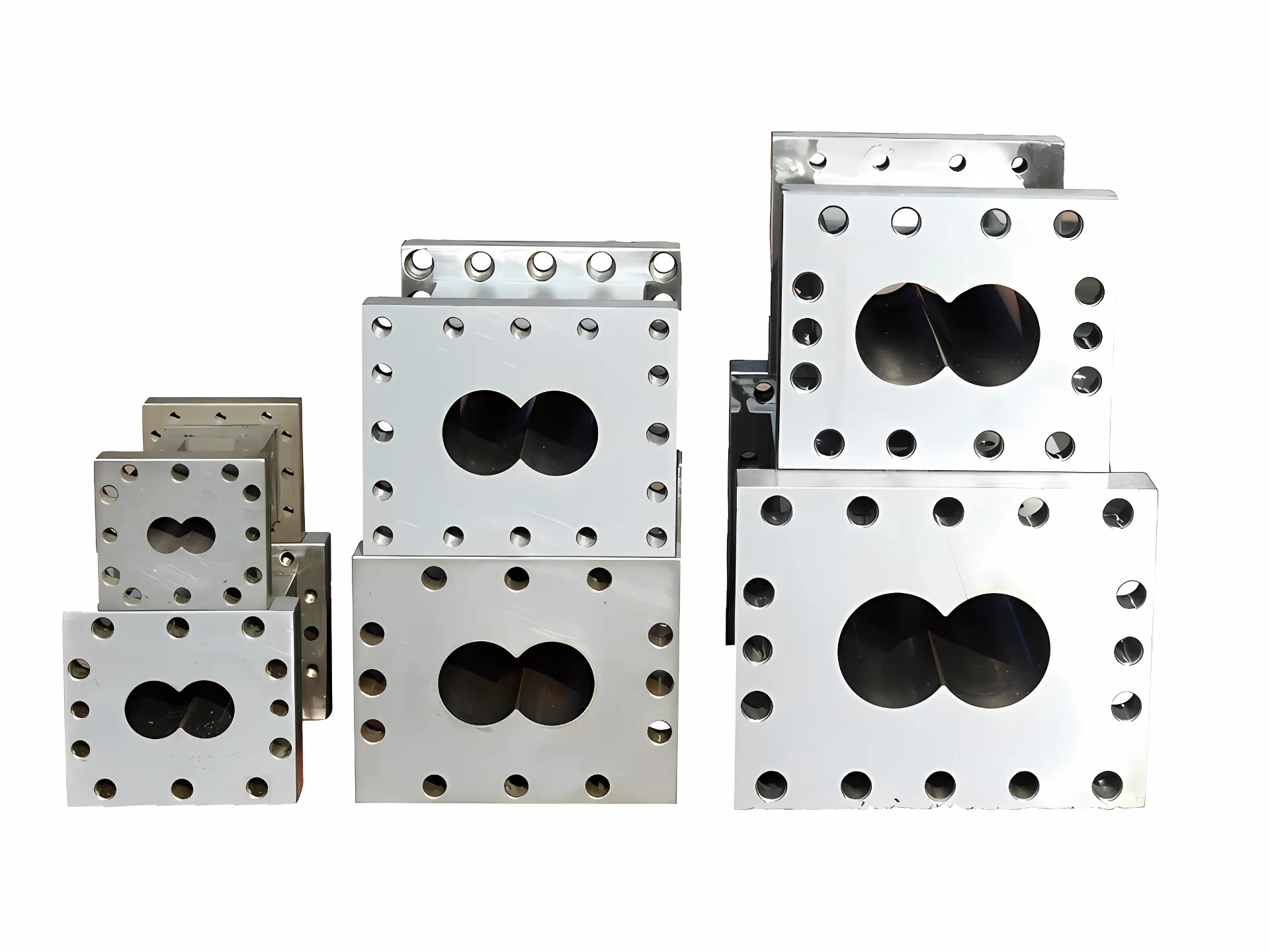

Core Components & Their Roles

Twin Screw & Barrel

Modular, co-rotating intermeshing screws provide excellent mixing, dispersing, and conveying efficiency for diverse formulations.

High-Torque Drive System

A powerful and precise motor with variable speed control (up to 600 rpm) ensures consistent torque for processing challenging materials.

Precision Feeding System

Accurate gravimetric or volumetric feeders ensure consistent material ratios, critical for reproducible experimental results.

PLC Control System

An intuitive touch-screen interface for setting parameters, monitoring real-time process data, and saving recipes for future use.

Technical Specifications (Model: LTE-15.5)

| Parameter | Specification |

|---|---|

| Screw Diameter | 15.5 mm |

| L/D Ratio | 40:1 (Customizable) |

| Maximum Screw Speed | 600 rpm |

| Main Motor Power | 1.1 kW |

| Temperature Control Zones | 5 Zones (Barrel) + 1 Zone (Die) |

| Output Capacity | 0.1 – 5 kg/hour |

| Control System | Siemens PLC with Touch Screen |

| Dimensions (L*W*H) | Approx. 1200 x 500 x 600 mm |

| Machine Weight | Approx. 150 kg |

Mini Lab Extruder Gallery

Get a Quote for Your Lab Extruder

Tell us about your research or application, and our specialists will configure the perfect solution for you.

Frequently Asked Questions

• General thermoplastics (PE, PP, EVA) with fillers (CaCO₃, talc, carbon black).

• Biodegradable masterbatches (e.g., PLA/PBAT + starch).

• High-concentration color masterbatches (up to 50% pigment).

• Antistatic masterbatches, polymer alloys, and various functional compounds.