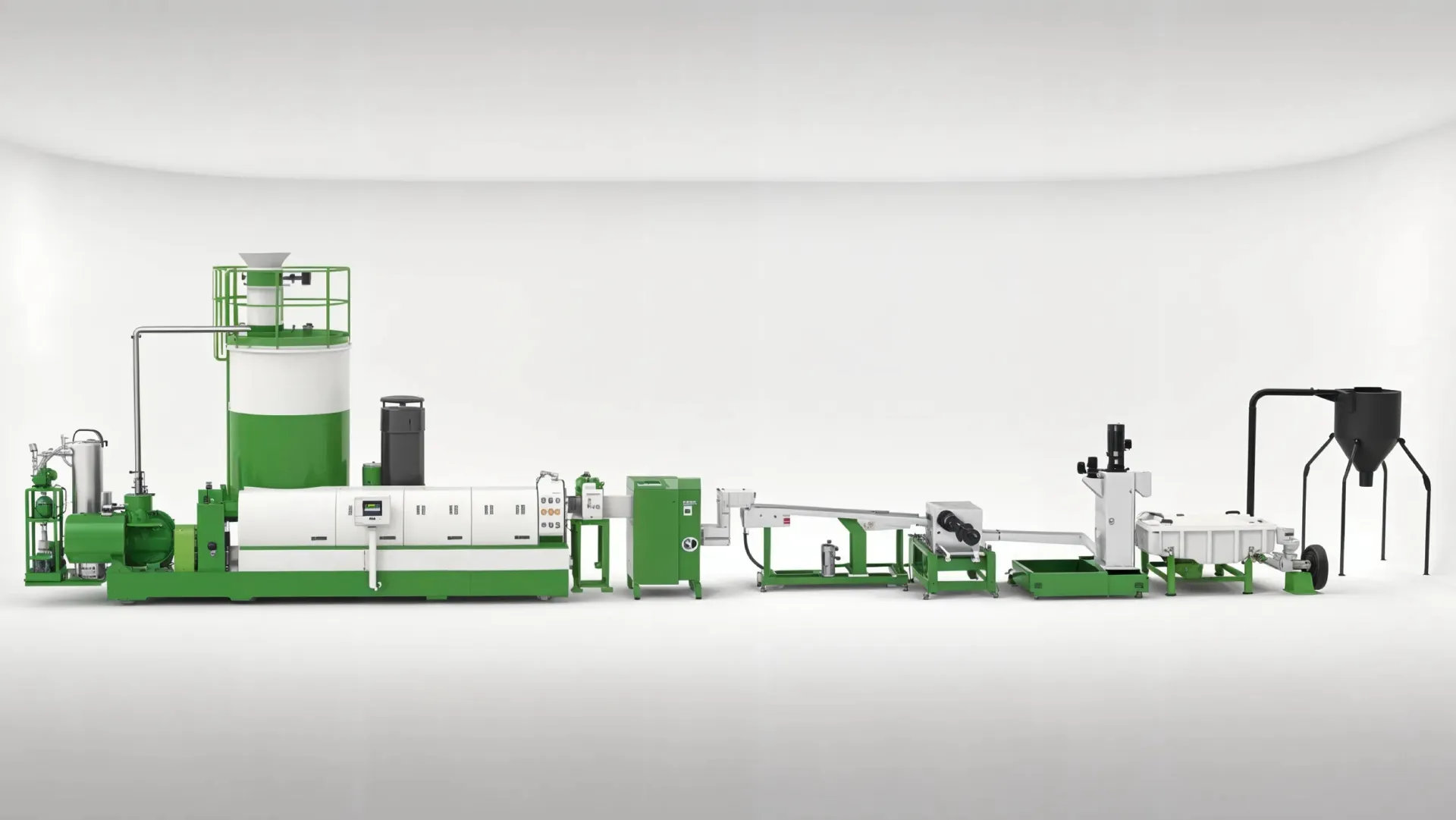

Melt-blown Non-Woven Fabric Recycling Machine

Transform low-density melt-blown non-woven scrap into high-value, high-MFI PP pellets. Our specialized line is engineered to overcome the unique challenges of recycling fluffy materials from masks, filters, and production waste.

Request a Technical Proposal

Request a Technical Proposal

Engineered for Non-Woven Fabrics

Standard recyclers fail with fluffy materials. Our machine is purpose-built with key advantages for processing melt-blown and other non-woven fabrics.

Mastering Low-Density Feeding

Our integrated cutter-compactor is the core technology that densifies fluffy material, solving common feeding issues like bridging and clogging for a stable, continuous process.

Preserving Material Integrity (High MFI)

The specialized extruder screw and gentle melting process are designed to minimize thermal degradation, preserving the high Melt Flow Index (MFI) of the original PP material.

Uniform Pellet Production

The strand-type (noodle cutter) pelletizing system ensures consistently sized and shaped cylindrical pellets, which are highly valued for reuse in manufacturing.

Key Technology Showcase

Our machine integrates advanced components to ensure efficient and stable processing of melt-blown fabrics.

Specialized Extruder

A specialized single screw extruder gently melts the pre-compacted material. The plastic scraps are well melted and plasticized in a 36D processing section.

- Double-Zone Vacuum Degassing: Efficiently removes volatiles and moisture.

- Gentle Melting: Preserves the high Melt Flow Index (MFI) of the original PP material.

- Optimized for Low Density: Ensures stable pressure and consistent plasticizing.

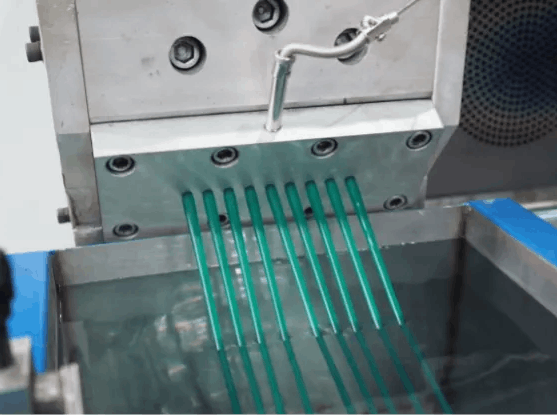

Noodle Cutter Strand Type Cutting System

This system is ideal for producing uniform cylindrical pellets. Molten plastic is extruded into strands, which are then cooled and cut to a precise length.

- 4-Meter Stainless Steel Cooling Trough: Provides ample cooling for high-quality pellets.

- Adjustable Design: The sink can be adjusted for optimal strand cooling and handling.

- Easy Maintenance: Designed for easy water changes and cleaning.

Our 4-Step Recycling Process

From fluffy waste to valuable resource, our automated line simplifies the entire process.

Feeding & Densifying

Melt-blown scrap is densified in the cutter-compactor for stable feeding.

Extrusion & Degassing

The material is melted, plasticized, and vacuum degassed to remove impurities.

Strand Cooling & Cutting

Molten PP is extruded into strands, cooled, and cut into uniform pellets.

Drying & Collection

The pellets are dewatered and stored, ready for reuse in new manufacturing.

Technical Parameters

| Model | ML85 | ML100 | ML130 | ML160 | ML180 |

|---|---|---|---|---|---|

| Output (kg/h) | 180~250 | 300~400 | 500~600 | 700~800 | 1000~1500 |

Frequently Asked Questions

Get a Custom Quote

Tell us about your melt-blown scrap and production goals. Our engineers will provide a tailored solution and a competitive quote.