Understanding Pelletizer Prices: A Cost Analysis of Water Ring vs. Strand Systems

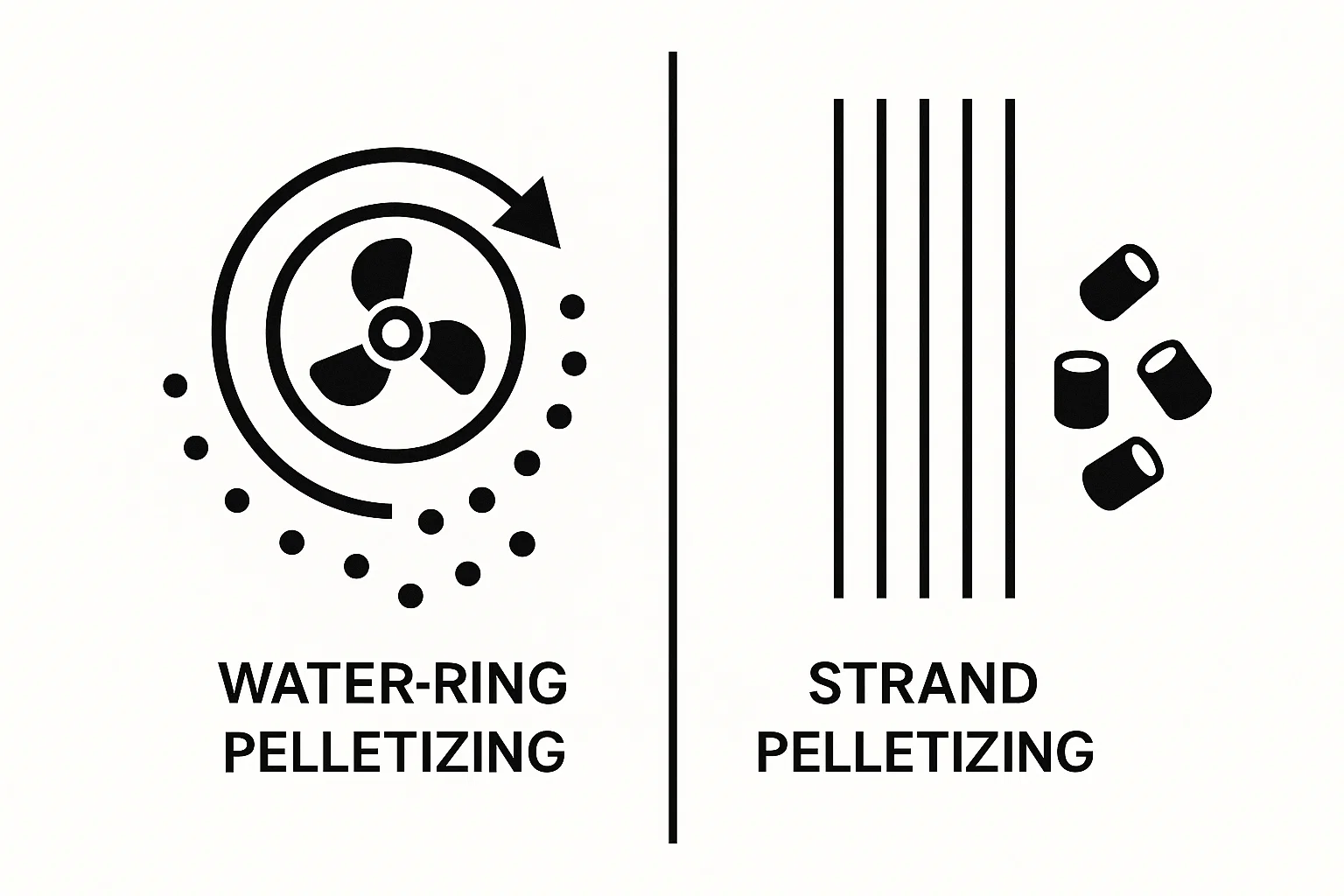

In the plastic recycling and polymer manufacturing sectors, converting plastic waste into uniform, reusable pellets is a critical final step. The choice of pelletizing technology directly impacts operational efficiency, end-product quality, and, most importantly, the bottom line. Two of the most prevalent technologies are water ring and strand pelletizing. While they achieve the same fundamental goal, their mechanisms, capabilities, and cost structures differ significantly.

This in-depth analysis moves beyond simple sticker prices to compare the comprehensive costs associated with water ring and strand plastic pelletizing machines. For plant managers, procurement specialists, and investors, understanding the total cost of ownership (TCO) is essential for making a profitable and sustainable investment.

Core Technologies: How They Work

Before delving into a price comparison, it’s crucial to understand the fundamental operational differences between these two systems.

The Water Ring Pelletizing Process

A water ring pelletizer is a type of hot-face cutting system. In this process, molten polymer is extruded through a die plate. As it emerges, rotating blades cut the polymer into pellets directly at the die’s face. A circulating ring of water immediately quenches the newly formed pellets and transports them as a slurry to a centrifugal dryer. The key characteristic is that the cutting happens before the plastic is cooled. The resulting pellets are typically rounded or slightly flattened.

The Strand Pelletizing Process

Strand pelletizing is a “cold-cut” system where molten polymer is extruded through a die to form continuous filaments, or strands. These strands are pulled through a water bath for cooling and solidification. After cooling, the hardened strands are fed into a pelletizer, where a set of rotating knives cuts them into cylindrical pellets. This method is known for its simplicity and versatility.

Initial Investment: A Head-to-Head Cost Comparison

The upfront purchase price is often the first consideration for buyers. In this category, there is a clear distinction between the two systems.

Why Strand Pelletizers Often Have a Lower Upfront Cost

Strand pelletizing systems generally have a lower initial capital investment. Their design is mechanically simpler, consisting of a die, a water trough, an air knife or dewatering unit, and the pelletizer unit itself. This straightforward engineering translates to lower manufacturing costs. For startups, small-scale operations, or businesses that require frequent material changeovers, the cost-effectiveness of a strand pelletizer makes it an attractive entry point into high-quality pellet production.

The Higher Initial Price of Water Ring Systems

Water ring pelletizers typically command a higher initial price. This is due to their more complex and integrated design, which includes a sophisticated cutting chamber, a precisely engineered die face, and a closed-loop water circulation and drying system. The technology offers a higher degree of automation, which contributes to the upfront cost but can yield significant operational savings down the line.

Beyond the Price Tag: Total Cost of Ownership (TCO)

A savvy investment analysis looks beyond the initial purchase to evaluate long-term operational and maintenance costs. The TCO often reveals a more nuanced financial picture.

Operational Costs: Labor and Automation

This is where water ring systems begin to show their long-term value. Their process is highly automated and requires minimal operator intervention once running. The automated start-up and continuous, stable production reduce the risk of process disruptions like strand breakage, which can be common in strand systems.

Strand pelletizing is more labor-intensive. Operators must manually thread the strands during startup and monitor the process for breaks or tangles, which can lead to downtime and require skilled oversight. For large-scale, continuous operations, these higher labor costs can significantly impact profitability over time.

Maintenance, Consumables, and Durability

Both systems require routine maintenance, but the focus areas differ.

-

Strand Pelletizers: The primary wear components are the cutting blades and the bed knife. Because they cut solidified plastic, there is more potential for cutter wear. The system’s open design, however, makes cleaning and maintenance straightforward and quick.

-

Water Ring Pelletizers: The knives also wear but often have a longer life due to cutting molten polymer. Maintenance is generally simple, with easy access to replace pelletizing knives. However, the water circulation system, including pumps and filters, requires regular checks to prevent blockages and ensure water quality.

Material Flexibility and Changeover Efficiency

Strand pelletizing systems offer superior flexibility. They are adaptable to a wide variety of polymers and are particularly well-suited for facilities that run frequent material or color changes. The simple, open components are easy to clean, minimizing downtime between jobs.

Water ring pelletizers are more specialized. They excel with materials like polyolefins (PE, PP) and polystyrene (PS). However, they are less suitable for sticky or high-heat polymers. While not as flexible as strand systems for frequent changes, their efficiency in dedicated, long production runs is unmatched.

Buyer’s Guide: Which System Aligns with Your Business Needs?

The optimal choice depends entirely on your specific operational requirements, budget, and long-term strategy.

Choose a Strand Pelletizer If:

-

Budget is a primary constraint: Your initial capital expenditure is limited.

-

You process diverse materials: Your production involves frequent changes between different polymers or colors.

-

You have smaller or experimental production runs: The flexibility and easy cleanup are ideal for non-continuous operations.

-

You have available skilled labor: Your team can manage the more hands-on operational requirements.

Opt for a Water Ring Pelletizer If:

-

You prioritize automation and lower labor costs: You run large-scale, continuous operations where minimizing operator intervention is key.

-

You process specific materials: Your primary feedstock is PE, PP, PS, or other compatible polymers.

-

Consistent pellet shape is critical: You require uniform, rounded pellets for better downstream processing and flow characteristics.

-

Factory floor space is limited: The compact design of water ring systems offers a significant advantage over the larger footprint of strand lines.

Conclusion: Partner with Rumtoo for an Optimized Solution

The choice between a water ring and a strand pelletizing machine is not merely about initial price; it’s a strategic decision that impacts your entire production ecosystem. A strand pelletizer offers a cost-effective and flexible solution, ideal for diverse and smaller-scale operations. In contrast, a water ring pelletizer represents a larger upfront investment that pays dividends through automation, reduced labor, and high-volume output for specific materials.

At Rumtoo, we specialize in providing high-performance, reliable plastic recycling equipment tailored to the unique demands of our clients. Our team of experts provides in-depth consultations to help you analyze your material requirements, production scale, and financial goals. We design and configure complete recycling lines, from shredders and washing systems to the perfect pelletizing solution for your needs. By partnering with us, you gain access to robust machinery and comprehensive global support to ensure your operation runs smoothly and profitably.

To determine the ideal and most cost-effective pelletizing system for your business, contact Rumtoo’s experts today for a personalized consultation and a detailed quote.