Transforming Plastic Waste into a Valuable Commodity

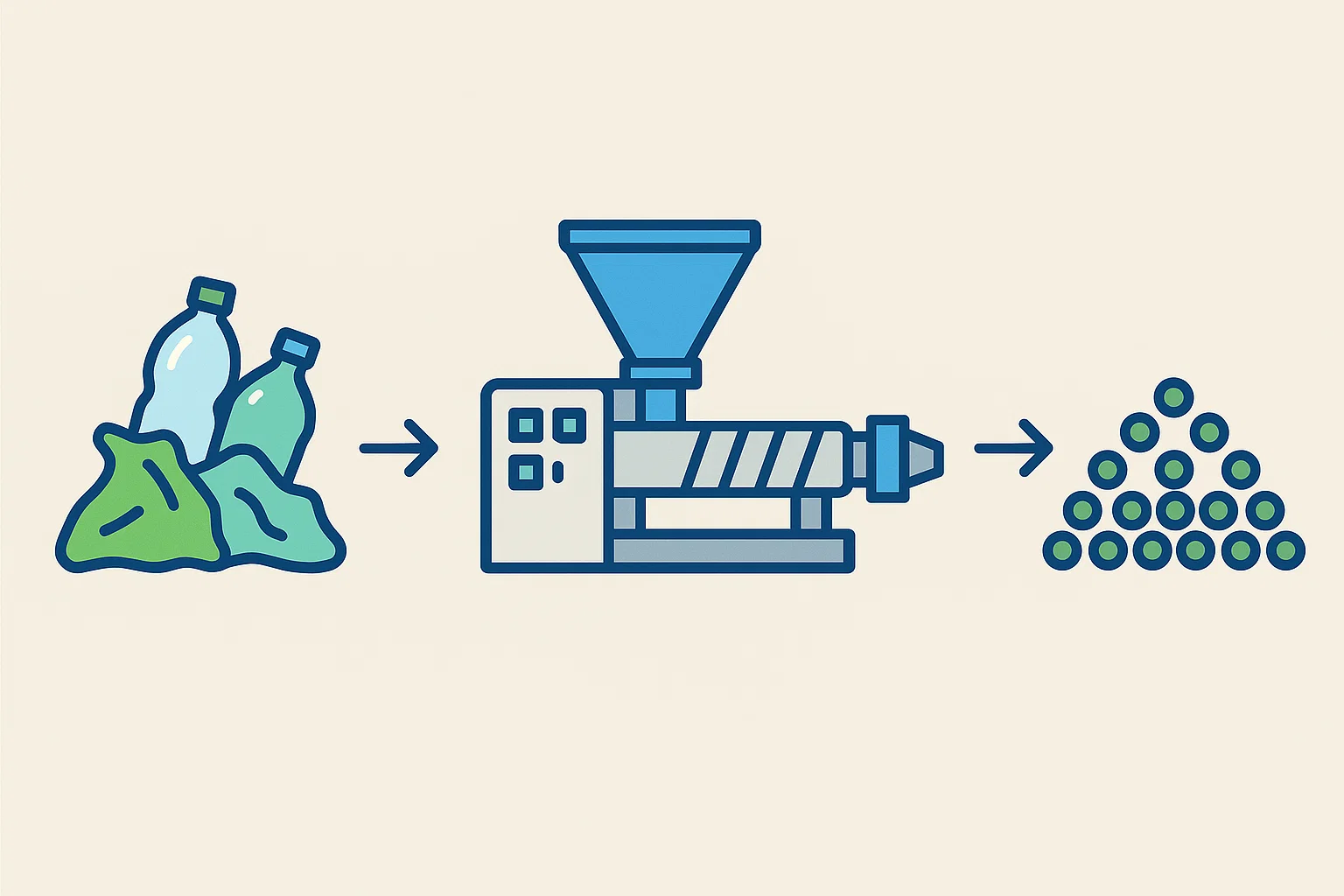

In an era of increasing environmental consciousness and regulatory pressures, the ability to efficiently recycle plastic waste is no longer just a sustainable practice but a significant economic opportunity. The global plastic pelletizing machine market was valued at approximately $4.3 billion in 2023 and is projected to reach around $6.7 billion by 2032. This growth is fueled by the rising demand for recycled plastics and the drive toward a circular economy. At the heart of this transformation is the plastic pelletizing process, a critical step that converts plastic waste into uniform, reusable pellets. These pellets serve as the raw material for a vast array of new products, from packaging and construction materials to automotive parts.

For industry professionals and potential buyers of recycling machinery, a thorough understanding of the pelletizing process is essential. This step-by-step guide will walk you through the entire journey, from the initial feeding of plastic scrap to the production of high-quality finished pellets, providing the technical insights needed to make informed decisions and optimize your recycling operations.

The Plastic Pelletizing Recycling Process: A Detailed Breakdown

The conversion of plastic waste into reusable pellets is a multi-stage process that requires precision-engineered machinery. Each step is crucial for ensuring the quality and consistency of the final product.

Step 1: Collection, Sorting, and Shredding

The journey begins with the collection and sorting of plastic waste. This initial phase is critical for the quality of the end product. Plastics are meticulously sorted by type (e.g., PET, HDPE, LDPE, PP), color, and contaminants. Advanced facilities may use automated technologies like optical sorters with infrared sensors to enhance sorting accuracy.

Once sorted, the plastic waste is shredded or granulated into smaller, more manageable flakes. This not only reduces the volume of the material but also increases its surface area, which facilitates more effective cleaning and melting in the subsequent stages.

Step 2: Cleaning and Drying

The shredded plastic flakes then undergo a rigorous cleaning process to eliminate contaminants such as dirt, labels, adhesives, and food residue. This is often achieved through washing systems that may use hot water or chemical agents to break down stubborn impurities. Thorough cleaning is non-negotiable, as even minor contaminants can compromise the structural integrity of the recycled material.

Following the wash, the plastic flakes must be completely dried. Any residual moisture can interfere with the melting process and negatively impact the quality of the pellets.

Step 3: Feeding and Melting (Extrusion)

The clean, dry plastic flakes are then fed into the pelletizing machine, typically via a hopper. From the hopper, the material enters the extruder, which is the core component of the pelletizing system. The extruder consists of a screw mechanism housed within a heated barrel.

As the screw rotates, it conveys the plastic forward while subjecting it to controlled heat and pressure. This process melts the plastic into a viscous, molten state. The temperature and screw speed are carefully regulated to ensure uniform melting and prevent material degradation. Some advanced systems incorporate degassing zones to remove trapped air, moisture, and volatile organic compounds (VOCs), which is particularly important when processing printed or slightly wet materials.

Step 4: Melt Filtration

Before the molten plastic is formed into pellets, it is forced through a filtration system. This screen changer removes any remaining physical impurities, ensuring the purity of the final pellets. High-quality filtration is crucial for producing recycled pellets that can be used in a wide range of applications.

Step 5: Pelletizing (Cutting) and Cooling

After filtration, the molten plastic is extruded through a die, forming continuous strands. This is where the pelletizing, or cutting, takes place. There are several methods for cutting the plastic strands into uniform pellets, each with its own advantages:

-

Strand Pelletizing: In this common method, the extruded strands are cooled in a water bath before being cut into pellets by a rotating cutter. This system is cost-effective and versatile, suitable for a wide range of polymers.

-

Water-Ring Pelletizing: Here, the pellets are cut at the die face, and a ring of circulating water immediately cools and transports them away. This method is efficient for thermoplastics like polyethylene and polypropylene.

-

Underwater Pelletizing: The entire cutting process takes place submerged in water. This provides rapid and uniform cooling, resulting in high-quality, spherical pellets. This system is ideal for high-volume production and can handle materials that are difficult to process in other ways.

The choice of pelletizing system depends on factors such as the type of plastic, required throughput, and desired pellet quality.

Step 6: Drying and Storage

The newly formed pellets are then dried to remove any remaining moisture from the cooling process. Once dry, they undergo a final quality control check for uniformity and purity before being packaged. These finished pellets are now a valuable raw material, ready to be sold to manufacturers for the production of new plastic products.

A Buyer’s Guide to Selecting the Right Pelletizing Machine

Choosing the right plastic pelletizing machine is a critical investment that directly impacts your operational efficiency, product quality, and profitability. When evaluating potential machinery, consider the following key factors:

-

Material Compatibility: Ensure the machine is designed to process the specific types of plastic you intend to recycle. Different polymers have varying melt flow indexes, viscosities, and processing requirements.

-

Throughput Capacity: Select a machine with a production capacity that aligns with your operational scale and future growth projections. An undersized system can create bottlenecks, while an oversized one leads to unnecessary energy consumption.

-

Pellet Quality Requirements: The intended application of the recycled pellets will dictate the required level of purity, uniformity, and shape. High-end applications may necessitate more advanced filtration and cutting systems.

-

Automation and Control Systems: Modern pelletizers often feature advanced automation and control systems for greater efficiency and consistency.

-

Energy Efficiency: Opt for machines with energy-saving features to reduce long-term operational costs.

-

Maintenance and Support: Consider the ease of maintenance, the availability of spare parts, and the level of technical support provided by the manufacturer. Regular maintenance is essential for the longevity and optimal performance of the equipment.

Industry Trends and the Future of Plastic Pelletizing

The plastic recycling industry is continuously evolving, driven by technological advancements and the growing demand for sustainable solutions. Key trends include the development of more energy-efficient machinery, enhanced filtration systems for producing higher-quality pellets from post-consumer waste, and the integration of intelligent control systems for process optimization.

The demand for recycled plastic pellets is on the rise, creating significant opportunities for businesses in the recycling sector. By investing in high-quality, efficient pelletizing machinery, you can position your operation to capitalize on this growing market.

Conclusion: Partnering for Success in Plastic Recycling

The step-by-step process of plastic pelletizing, from feeding raw scrap to producing finished pellets, is a sophisticated operation that transforms waste into a valuable resource. Understanding the nuances of each stage is crucial for any industry professional looking to enter or expand their presence in the plastic recycling market.

At Rumtoo, we specialize in providing high-performance, reliable plastic recycling machinery designed to meet the diverse needs of the modern recycling industry. Our expertise and cutting-edge technology can help you optimize your pelletizing process, ensuring the production of high-quality recycled pellets that meet the demands of today’s market.

Ready to enhance your plastic recycling capabilities? Contact us today to request a quote or to learn more about how our advanced pelletizing solutions can benefit your business.