Manufacturers across the USA and Europe increasingly rely on recycled polyolefins to meet sustainability targets without compromising on performance. Yet the economics only stack up when pellet quality is consistently high—clean cut surfaces, minimal gels, stable melt flow, and tight dimensional control. This article distils practical, plant-proven methods for running a plastic pelletizing machine on HDPE/PP flakes, with a focus on force-feeding, extrusion stability, filtration strategy, and pellet uniformity. Throughout, we highlight how Rumtoo Machine integrates the mechanics and controls so your line behaves as one tuned system rather than a set of parts.

What “High Quality” Means in Practice

-

Processability: Pellets feed smoothly with low dust and no surging on downstream film, blow-moulding, or injection equipment.

-

Appearance: Consistent colour and surface finish with low black speck counts.

-

Property stability: Narrow MFI/MFR window and low odour, supported by sound degassing.

-

Compliance & documentation: Traceable lots, energy and yield reporting, and safety conformity (OSHA/CE) for audits.

1) Win at the Source: Clean, Dry, Sorted Flakes

A pelletising line cannot fully compensate for poor incoming material. For HDPE/PP, the input must be clean, dry, and correctly classified.

Clean: Remove paper, labels, elastomers, aluminium rings, and wood. These either degrade into gels or erode screens and die plates. Install magnetic and eddy-current separation, and use optical sorting (NIR and colour) to push out incompatible polymers.

Dry: Moisture in polyolefin flakes isn’t absorbed like PET, but free water flashes in the die, causing pits and voids. A practical target is ≤0.2% moisture at the feeder. Hot-wash, rinse, then centrifugal drying with air knives is a robust sequence.

Sorted and sized: Tight size distribution (<12 mm typical) raises bulk density and improves feed stability. Remove fines that fluidise and cause force-feeder torque drift.

Why it matters: Even small moisture increases drive up rejects. (Figure 1: Effect of Flake Moisture on Pellet Reject Rate.) Inline moisture checks at silo discharge and shift-wise loss-on-drying on retained samples give an auditable trail.

Figure 1. Effect of flake moisture on pellet reject rate.

2) Feeding Strategy: Why a Force-Feeder Is Non-Negotiable for Flakes

Flakes are low-bulk-density, springy, and trap air. Left to gravity, they bridge in the hopper and starve the extruder, causing a saw-tooth pattern in melt pressure and temperature that shows up as pellet length variation and colour banding.

Force-Feeder Advantages

-

Mass-flow stability: A compaction/stuffing screw densifies flakes and pushes a steady charge into the main screw.

-

Lower energy per kg: The extruder does less “dry compaction” and more plasticising.

-

Less entrained air: Improves degassing efficiency and reduces die-face popping.

-

Synchronised control: In Rumtoo Machine lines, feeder speed and torque are VFD-linked to extruder load, maintaining a narrow pressure band at the die even when bulk density varies by supplier or season.

For rigid flake applications, Rumtoo Machine’s single-screw pelletising machine with force-feeder and vacuum venting is a proven architecture; see the rigid plastic single-screw pelletising machine for a typical configuration.

3) Extrusion: Stabilise Melt Pressure and Temperature

Once feeding is steady, melt quality depends on screw design, barrel heating, and venting.

Screw and Barrel Setup (single-screw):

-

Geometry: For recycled HDPE/PP, a barrier or mixing section with L/D 28–36 is common. Use a distributive mixer (e.g., Maddock type) to polish gels without excessive shear.

-

Temperature profile: Aim for HDPE 180–220 °C and PP 190–230 °C depending on MFI and colour masterbatch; tune PID loops to hold ±1–2 °C to avoid oscillations that print as pellet colour shifts.

-

Venting: Use one atmospheric and one vacuum vent to strip water, surfactants, and volatiles. Keep condensate traps clear and monitor the vacuum level to protect against odour spikes.

Melt Pressure Strategy:

Measure at least before the screen changer and before the die. This separation helps you tell whether rising pressure is due to filter loading or throughput limits. A melt gear pump after the filter decouples screw speed from die flow, flattening pressure ripple and improving pellet length control.

Targets that work: Die pressure 80–200 bar with CV <3–5%; temperature stable within a few degrees at a constant rate. Use alarms based on pressure slope (bar/min), not just absolute value, to predict screen changes.

4) Filtration: Select the Right Screen Changer for Your Contamination

Filtration is the last defence against label residues, paper, aluminium fines, and elastomer fragments that become black specks and strand breaks.

Options and When to Use Them

-

Manual slide-plate – Suitable for low contamination and smaller lines; expect brief stops and small process blips.

-

Hydraulic dual-piston (semi-continuous) – Good middle ground for ash <2–3%; short changeovers, limited disturbance.

-

Continuous belt/rotary with back-flush – For heavier contamination; steady pressure, extended screen life.

-

Self-cleaning drum/automatic melt filter – For very dirty streams; highest CAPEX, maximum uptime, minimal ripple.

Selection rule of thumb: If melt pressure rises >20–30 bar/hour at a constant rate, you need either a larger filter area, finer gradient packs, or a continuous system. If black specks persist with stable pressure, step down mesh size or move to back-flush capable filtration to prevent gel breakthrough.

Rumtoo Machine integrates screen-changer logic with the HMI so operators see projected change time (based on pressure slope), cutting unplanned stops.

5) Pelletising and Cooling: The Last 2% Everyone Sees

Even perfect melt can be ruined by poor cutting or unstable cooling. Choose a system that fits your resin and rate:

-

Water-ring (die-face) pelletiser: Compact, quick to start/stop, ideal for HDPE/PP with mid-range MFI.

-

Hot-face air-cooled die: Useful for blends prone to sticking or where water handling must be minimised.

-

Strand pelletising: Simple and robust; more floor space; strands can snap if gels or pressure blips persist.

-

Underwater pelletising: Best pellet sphericity and narrow size distribution; higher CAPEX and water-loop complexity.

Uniformity settings:

-

Match die hole count and gear-pump flow to hit the target pellet length (e.g., 3–4 mm) without over-shearing.

-

Set blade pressure/gap per specification to avoid “angel hair” (too hot/soft) or chipped pellets (too aggressive).

-

Keep the cooling loop closed-circuit and filtered; control temperature tightly to avoid differential shrinkage and hazing.

-

Use a vibration classifier with screens chosen so oversize/undersize stays within a single-digit percentage, and reprocess out-of-spec gently to protect colour and MFI.

6) What to Trend Every Shift

Quality claims are easier to defend when your data is tidy. Trend:

-

Melt pressure and temperature at pre-filter and pre-die points.

-

Force-feeder torque/current as a proxy for bulk density swings.

-

Screen life (kg per screen) and pressure slope to compare flake suppliers and wash settings.

-

Vacuum level at vents to catch seal wear or condensate buildup.

-

Pellet colour (Lab*), MFI/MFR, moisture, bulk density, and gel counts on finished pellets.

7) System Thinking: Link Wash Line and Pelletiser

The best plants link upstream and downstream:

-

Wash chemistry & temperature influence odour and gel formation; rinse thoroughly to reduce surfactant carry-over that blinds screens.

-

Dryer settings vs force-feeder torque: Drive moisture down without creating static that induces bridging. Pair with hopper agitators or bridging-breakers where needed.

-

Sorting resolution: For clarity-critical PP, elevate NIR/colour sorting to prevent barrier labels and mixed polymers from entering the melt.

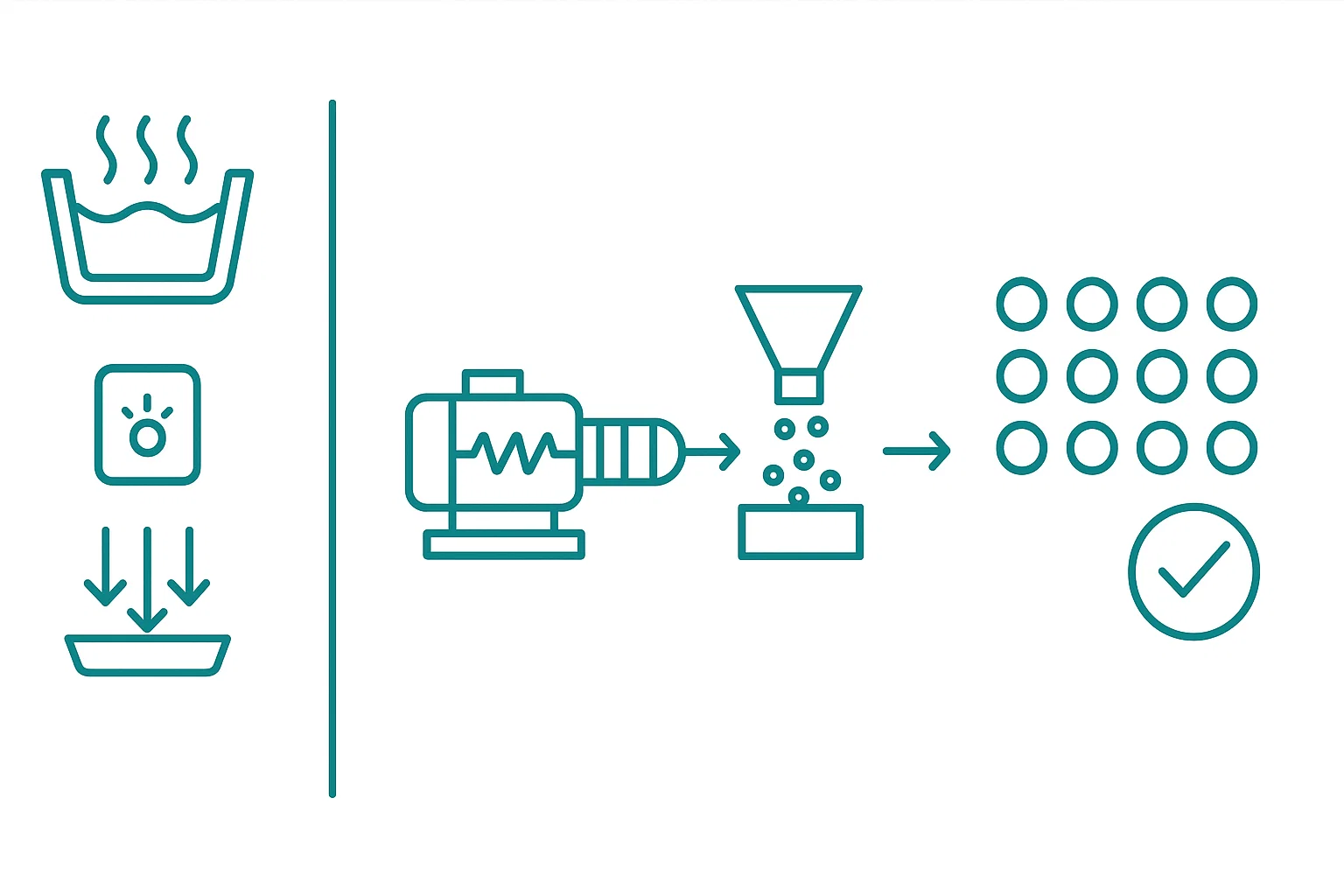

Figure 2. Typical HDPE/PP flake-to-pellet workflow—from feedstock through washing, drying, force-feeding, extrusion, filtration, gear pump, die-face pelletising, cooling, classification, and storage.

8) Safety, Compliance, and Energy for USA & Europe

-

Safety: Design to OSHA practices in the USA (lock-out/tag-out, interlocked cutter guards) and CE expectations in Europe (EN ISO 12100 risk assessment; appropriate PLr for safety functions).

-

Dust & housekeeping: Control dust at cutters/classifiers; consider ATEX where applicable.

-

Energy efficiency: High-efficiency motors with VFDs, insulated barrels, and gear pumps reduce kWh/kg. Closed-loop water systems lower consumption and scaling.

-

Noise management: Enclose noisier assets (strand cutters, air knives) to meet local occupational limits.

9) Quick-Start Setpoints (Typical for Recycled HDPE on Single-Screw)

-

Flake moisture at feeder: ≤0.2%

-

Screw speed: 70–150 rpm (depends on L/D and diameter)

-

Melt temperature: 190–210 °C

-

Die pressure: 100–160 bar with gear pump; ripple ≤5 bar

-

Screen pack: Gradient such as 60/100/60 for clean material; escalate to a continuous belt filter for dirtier streams

-

Pelletiser: Water-ring die-face, 3–4 mm target pellet length; classifier window ±1 mm

Rumtoo Machine will fine-tune these during commissioning and train operators to maintain them as material mix and seasons change.

Frequently Asked Questions

1) Do I really need a force-feeder for HDPE/PP flakes?

Yes. Flakes are compressible and low-density; a force-feeder stabilises mass flow, reduces entrained air, and flattens pressure ripple—directly improving pellet uniformity and screen life.

2) What screen mesh should I start with, and when do I upgrade?

Start with a 60/100/60 gradient for relatively clean streams. If pressure rises more than 20–30 bar/hour or black specks persist, move to finer media or a continuous/back-flush system.

3) How do I minimise odour from post-consumer material?

Improve hot-wash effectiveness, ensure proper drying, and use two-stage venting (atmospheric + vacuum). Keep the melt temperature stable and prevent prolonged high shear that can create aldehydes.

4) Water-ring vs strand pelletising—what’s better for HDPE/PP flakes?

Water-ring die-face is compact and forgiving for most HDPE/PP rates. Strand is robust and economical but more sensitive to gels; underwater offers the tightest size distribution at higher CAPEX.

Why Rumtoo Machine

Rumtoo Machine delivers complete HDPE/PP flake pelletising systems—force-feeder, single-screw extruder, vacuum venting, screen changer, gear pump, and pelletiser—engineered as a coherent control system. Customers in the USA and Europe benefit from:

-

Experience commissioning lines from 300 kg/h to multi-tonne scales.

-

Expertise in process integration, ensuring melt pressure and temperature remain flat even when feedstock varies.

-

Authoritativeness through thorough FAT/SAT documentation, operator SOPs, and quality records.

-

Trustworthiness via transparent energy/yield reporting and responsive after-sales support.

Call to Action

Ready to raise pellet quality, cut rejects, and prove consistency to demanding buyers? Speak with Rumtoo Machine today. We’ll specify the right plastic pelletizing machine architecture for your contamination level and throughput, integrate the correct screen-changer and gear pump, and commission the line to deliver stable, high-value pellets.

Explore configurations—starting with our rigid plastic single-screw pelletising machine—or request a quote to begin your upgrade.