In today’s manufacturing and packaging landscape, laminated plastic films are ubiquitous. From crisp packets and coffee bags to medical packaging and high-barrier food pouches, their unique properties—combining strength, flexibility, and preservation—make them indispensable. Yet, this very complexity presents one of the most significant challenges in the recycling industry.

For years, the consensus was that multi-layer, laminated films were largely unrecyclable. Their fused layers of different polymers, often including PE (Polyethylene), PET (Polyethylene Terephthalate), PA (Polyamide), and aluminium, seemed impossible to separate economically.

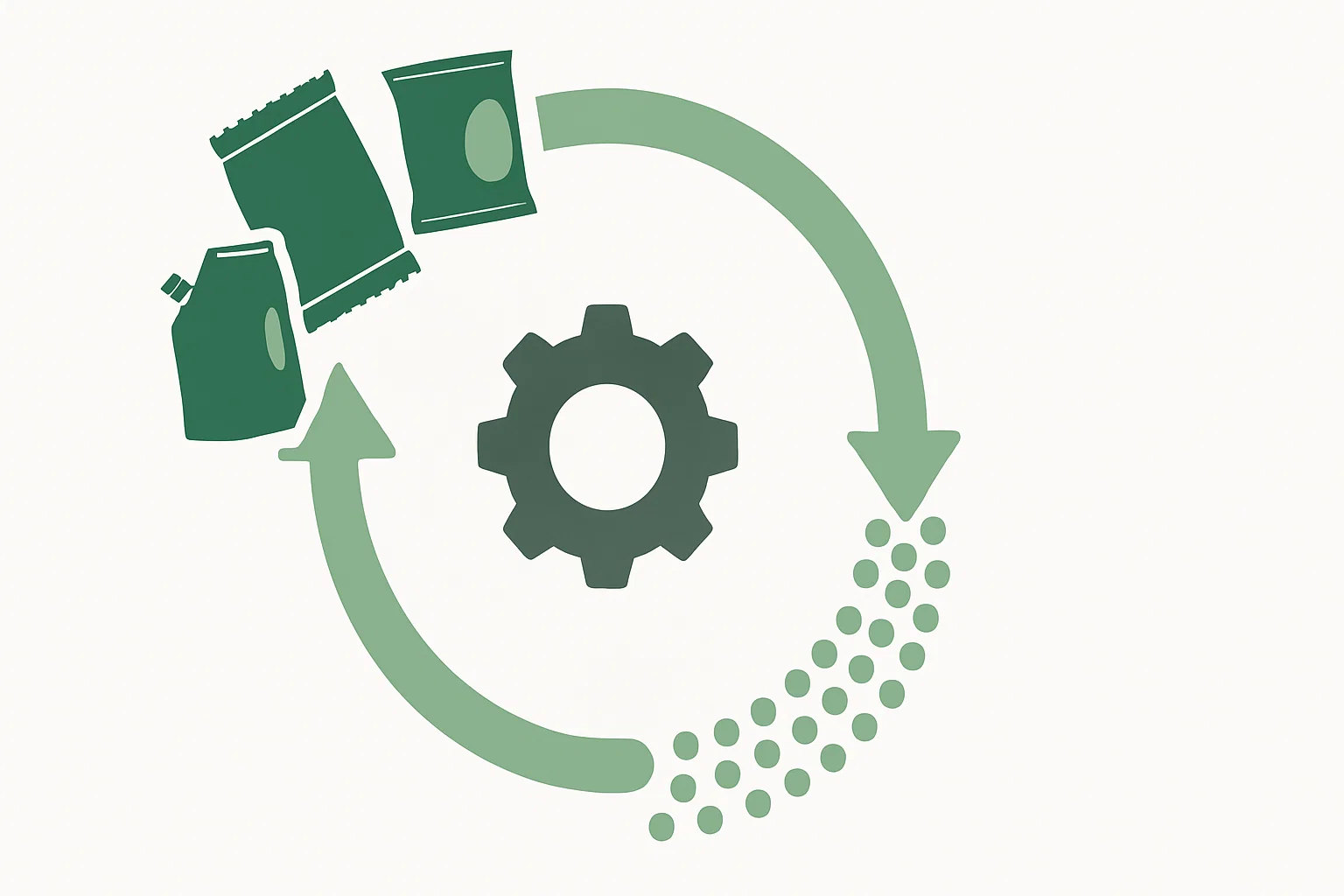

However, technology does not stand still. The question is no longer if we can recycle laminated plastic film, but how we can do it efficiently and profitably. The answer lies in advanced processing technology, with the pelletizing machine at its very core. At Rumtoo Machine, we specialise in developing sophisticated recycling lines that make this transformation possible, turning a problematic waste stream into a valuable resource.

This article explores the challenges of laminated film recycling and provides a comprehensive overview of how a state-of-the-art pelletizing machine provides a robust and commercially viable solution.

The Fundamental Challenge: Why is Laminated Film So Difficult to Recycle?

To appreciate the solution, one must first understand the problem. Laminated or multi-layer films are engineered composites. Each layer serves a specific purpose:

-

Outer Layer (e.g., PET, BOPP): Provides printability, gloss, and structural integrity.

-

Barrier Layer (e.g., EVOH, PA, Aluminium): Prevents oxygen, moisture, and light from degrading the contents.

-

Sealant Layer (e.g., PE, CPP): Allows the package to be heat-sealed.

The challenge arises because these different polymers have incompatible chemical properties and, crucially, different melting points. When processed in a traditional recycling system designed for single-polymer streams (mono-materials), the result is a low-quality, unusable material. Attempting to separate these microscopically thin, bonded layers is technically complex and, until now, has been economically unfeasible on an industrial scale.

The Paradigm Shift: From Separation to Homogenisation

Modern recycling technology, pioneered by companies like Rumtoo Machine, takes a different approach. Instead of attempting to separate the inseparable, the goal is to melt, mix, and homogenise the different polymers into a new, consistent composite material. This is where the advanced pelletizing machine becomes the hero of the process.

A pelletizing line does not just melt and chop plastic; it is an integrated system designed to handle the specific challenges posed by laminated films, such as inks, moisture, and varying melt flow indices (MFI).

The Heart of the Solution: Inside a Modern Pelletizing Machine

A pelletizing machine for laminated films is far more than a simple extruder. It is a sophisticated piece of engineering with several critical components working in concert. Let’s break down the process and the technology that Rumtoo Machine integrates into its systems.

1. Pre-Processing: Shredding and Densifying

Before entering the pelletizer, the loose, low-density film waste must be prepared. This typically involves a heavy-duty shredder or a cutter-compactor (also known as an agglomerator), which cuts, mixes, and pre-heats the material, densifying it into a more manageable, free-flowing state. This step is crucial for ensuring a stable and consistent feed into the extruder.

2. The Extruder: The Core of Transformation

The densified material is fed into the extruder. Here, a specially designed screw within a heated barrel conveys, melts, and mixes the plastic. For laminated films, the screw design is paramount. Rumtoo Machine engineers its extruder screws to create high shear and intensive mixing, ensuring that the different polymers are thoroughly homogenised into a consistent molten blend.

3. The Degassing System: A Critical Feature

Laminated films are almost always printed and can contain residual moisture. When heated, the inks, coatings, and moisture turn into gas (volatiles). If trapped in the final pellets, these gases would create structural weaknesses and imperfections.

To counter this, our advanced pelletizing machine lines feature highly efficient degassing zones. These are sections of the extruder barrel with vacuum ports that aggressively vent and extract these volatiles from the molten plastic, resulting in a purer, more stable final product. Double-stage or two-zone degassing is often essential for heavily printed or contaminated films.

4. Melt Filtration: Ensuring Purity

The molten plastic may still contain non-plastic contaminants like paper fibres, wood chips, or unmelted metals. A robust melt filtration system, such as a dual-piston screen changer, removes these impurities before the plastic proceeds to the pelletizing stage. This ensures the final pellets are free from contaminants that could damage downstream processing equipment or compromise the final product.

5. Pelletizing: Creating Uniform Pellets

Once melted, mixed, degassed, and filtered, the clean molten polymer is forced through a die plate with numerous small holes. A set of rotating blades cuts the strands as they exit the die, forming uniform pellets. The most common method for film recycling is water-ring die-face pelletizing, where the pellets are immediately cooled by a spray of water and transported for dewatering and drying.

The entire process transforms a heterogeneous mix of laminated film waste into clean, dense, and uniform pellets, ready for reintroduction into the manufacturing cycle.

Workflow of a Laminated Film Recycling Line

To better visualise the process, here is a typical workflow for a Rumtoo Machine plastic film recycling line.

Rumtoo Machine: Laminated Film Pelletizing Workflow

Film Waste Input (Baled/Loose)

Shredder / Cutter-Compactor

Extruder (with Degassing)

Melt Filter & Pelletizing Head

Cooling, Dewatering & Final Pellets

The Economic and Environmental Value of Recycled Pellets

The output of this process—high-quality composite pellets—holds significant value. While they may not be suitable for food-grade applications, they are ideal for manufacturing a vast range of durable products:

-

Injection Moulding: Creating parts like buckets, crates, and automotive components.

-

Extrusion: Manufacturing plastic lumber for decking, fencing, benches, and posts.

-

Blow Moulding: Producing non-critical containers and bottles.

By investing in a capable pelletizing machine, manufacturers and recyclers can:

-

Create a New Revenue Stream: Turn a costly waste product into a saleable commodity.

-

Enhance Sustainability: Divert tonnes of plastic from landfill or incineration, contributing to a circular economy.

-

Reduce Disposal Costs: Lower the financial burden associated with waste management.

Choosing the Right Pelletizing Machine: Key Considerations

Not all pelletizers are created equal, especially when dealing with challenging materials like laminated films. When selecting a system, industry professionals should focus on:

-

Screw and Barrel Design: Is it optimised for the intensive mixing and melting of multi-polymer materials?

-

Degassing Efficiency: Does the machine have adequate, high-performance degassing to handle printed and potentially moist films?

-

Throughput and Energy Efficiency: The system must deliver the required output (kg/hr) without consuming excessive energy. Modern designs from Rumtoo Machine incorporate energy-efficient motors and heating systems.

-

Automation and Control: A user-friendly PLC control system simplifies operation, ensures process stability, and minimises the need for manual intervention.

At Rumtoo Machine, we pride ourselves on consulting with our clients to configure a soft plastic single screw pelletizing machine that is perfectly tailored to their specific input materials and output requirements.

Performance Comparison: The Rumtoo Machine Advantage

Investing in advanced technology yields tangible results. A system purpose-built for laminated films will outperform a standard, general-purpose machine in both pellet quality and operational efficiency.

Efficiency Comparison: Pelletizing Laminated Film

Performance Index High Medium Low

Pellet Quality Std Rumtoo

Throughput (kg/hr) Std Rumtoo

Standard System Rumtoo Machine Advanced System

This chart illustrates how a Rumtoo Machine system, engineered specifically for laminated films, delivers superior pellet quality (fewer voids, better consistency) and higher throughput compared to a standard system not optimised for these challenges.

Frequently Asked Questions (FAQ)

1. Can all types of laminated film be recycled with a pelletizing machine?

Most common PE/PET, PE/PA, and other polyolefin-based laminates can be processed effectively. However, films with very high percentages of non-thermoplastic materials (like thick aluminium layers) or those containing PVC can be more challenging and may require specialised system configurations or pre-sorting. It’s always best to have your material tested.

2. What is the quality of the final pellets from mixed laminated films?

The resulting pellets are a polymer composite. Their quality is excellent for non-cosmetic, durable goods applications. While they won’t match the properties of virgin, single-polymer resins, they possess a unique and valuable profile of their own, often combining toughness and rigidity. The key is finding the right end market for this recycled material.

3. How much energy does a Rumtoo Machine pelletizing line consume?

Energy efficiency is a primary design focus at Rumtoo Machine. We utilise high-efficiency motors, advanced heating elements with superior insulation, and intelligent control systems that optimise energy usage based on the material being processed. While recycling is an energy-intensive process, our machines are engineered to have one of the lowest kWh/kg ratios in the industry.

Conclusion: Turn Your Laminated Film Waste into an Opportunity

The recycling of laminated plastic film is no longer a distant dream but a present-day reality. It is a testament to technological innovation in the face of complex material science. With a robust, intelligently designed pelletizing machine, what was once a problematic waste stream can be efficiently converted into a high-value resource, driving both economic growth and environmental stewardship.

The key lies in partnering with an expert who understands the nuances of the material and the machinery. Rumtoo Machine stands at the forefront of this technology, providing the experience, expertise, and cutting-edge equipment to help your business succeed in this evolving market.

Ready to unlock the potential of your plastic film waste? Contact the experts at Rumtoo Machine today for a personalised consultation or to request a quote for your bespoke pelletizing machine solution.