Rigid Plastic

Single Screw Pelletizing Machine

Efficiently recycle rigid plastic waste like PP, PE, ABS, PC, PS flakes and scraps into high-quality reusable pellets. Our advanced technology ensures superior plasticization and output.

Request a QuoteWhy Our Rigid Plastic Pelletizer?

High Efficiency

Optimized screw design and powerful motor ensure high throughput and excellent melt quality for rigid plastics.

Versatile Material Handling

Processes a wide range of rigid plastics including PP, PE, ABS, PC, PS in flake or crushed form.

Eco-Conscious Recycling

Transform plastic waste into valuable resources, reducing landfill and promoting a circular economy.

Advanced Filtration

Multiple screen changer options (plate, column, automatic) for effective impurity removal and continuous operation.

Robust & Durable

Built with high-quality components for long service life and reliable performance in demanding industrial environments.

Customizable L/D Ratios

Various screw L/D ratios available to perfectly match material characteristics and processing requirements.

Simplified Pelletizing Process

Material Feeding

Crushed rigid plastic flakes or scraps are consistently fed into the extruder hopper.

Melting & Plasticizing

Material is conveyed, melted, and homogenized by the high-efficiency single screw extruder.

Degassing & Filtration

Forced vacuum exhaust removes volatiles and moisture; melt is filtered through a screen changer.

Pelletizing

Molten plastic is extruded through die holes and cut into uniform pellets (water strands or water ring method).

Cooling & Drying

Pellets are rapidly cooled by water, then dewatered and dried, ready for storage or reuse.

Versatile Applications

Plastic Recyclers

Process post-consumer and post-industrial rigid plastic waste (e.g., bottles, containers, pipes, profiles) into high-value pellets for resale.

In-house Manufacturing Scrap

Recycle production waste from injection molding, blow molding, or extrusion (e.g., sprues, runners, defective parts) directly on-site.

Plastic Compounders

Ideal for producing masterbatches or compounded materials by incorporating additives, fillers, or colorants with recycled rigid plastics.

Packaging Industry

Recycle rigid packaging materials like crates, pallets, and containers made from PP or HDPE.

Automotive & Electronics

Reclaim rigid plastic components from end-of-life vehicles or electronic waste (e.g., ABS, PS, PC parts).

Custom Pellet Production

Create specific pellet grades from various rigid plastic sources to meet unique customer or market demands.

See Our Rigid Plastic Pelletizer in Action

Witness the transformation of rigid plastic waste into uniform, high-quality pellets. (Video placeholder)

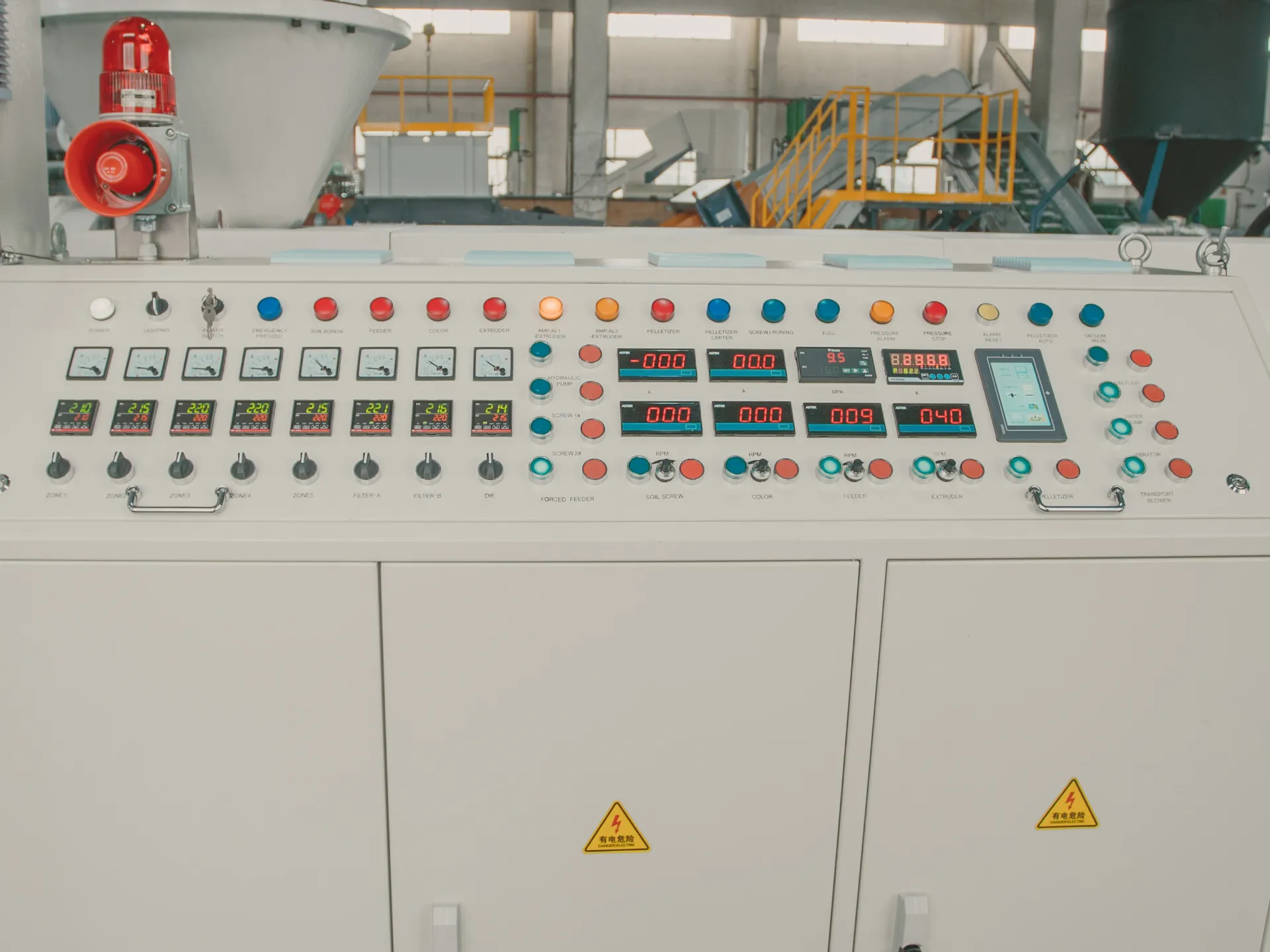

Core Machine Components

Feeding System

Reliable feeding of crushed rigid plastics via belt conveyor or screw feeder into the extruder, ensuring a consistent material flow.

Single Screw Extruder

High-performance screw and barrel design optimized for rigid plastics, featuring efficient melting, mixing, and optional vacuum degassing for superior pellet quality.

Melt Filtration System

Choice of Plate, Column, or Automatic screen changers for continuous melt filtration, removing contaminants effectively.

Pelletizing System

Available with Water Strands Pelletizing for easy operation or Water Ring Pelletizing for highly uniform pellets and automated process, suitable for various rigid materials.

Technical Specifications (SJ Series)

| Machine Model | Pelletizing Method | Filtering Method | Screw Dia. (mm) | L/D Ratio | Motor Power (KW) | Capacity (kg/h) |

|---|---|---|---|---|---|---|

| SJ85-100 | Water strands pelletizing | Plate screen changer | 85 | 28-33:1 | 55-75 | 100-200 |

| 100 | 10:1 | |||||

| SJ100-120 | Water strands pelletizing | Plate screen changer | 100 | 28-33:1 | 90-110 | 200-350 |

| 120 | 10:1 | |||||

| SJ130-150 | Water strands pelletizing | Plate screen changer OR Column screen changer |

130 | 28-33:1 | 132-160 | 400-550 |

| 150 | 10-12:1 | |||||

| SJ150-160 | Water ring Pelletizing | Column screen changer OR Automatic screen changer |

150 | 28-33:1 | 185-200 | 500-650 |

| 160 | 12:1 | |||||

| SJ160-180 | Water ring Pelletizing | Automatic screen changer | 160 | 28-33:1 | 220-250 | 700-900 |

| 180 | 12:1 | |||||

| SJ180-200 | Water ring Pelletizing | Automatic screen changer | 180 | 28-33:1 | 280-315 | 900-1200 |

| 200 | 12:1 |

The pelletizing line is suitable for PP, PE, ABS, PC, PS flakes and scraps pelletizing. The extruder uses a high-efficiency screw barrel to ensure the plasticizing effect and high output of the finished product. The forced vacuum exhaust system effectively removes low molecular impurities, moisture, and ink. According to the contamination of material and customers’ habits, a variety of screen changers are available: plate screen changer, column screen changer, and automatic screen changer. For different purposes, a variety of screw L/D ratios, two-stage extrusion systems, and pelletizing methods are available.

Machine Gallery

Get Your Custom Solution & Quote

Discuss your rigid plastic recycling needs with our experts. We’ll design a tailored pelletizing line and provide a competitive quote.

Frequently Asked Questions

Water Ring Pelletizing: Molten plastic is cut directly at the die face by rotating blades, and pellets are immediately quenched by a water ring. This method produces more uniform pellets and is often preferred for higher capacities or certain material types.