What is a Single Screw Extruder?

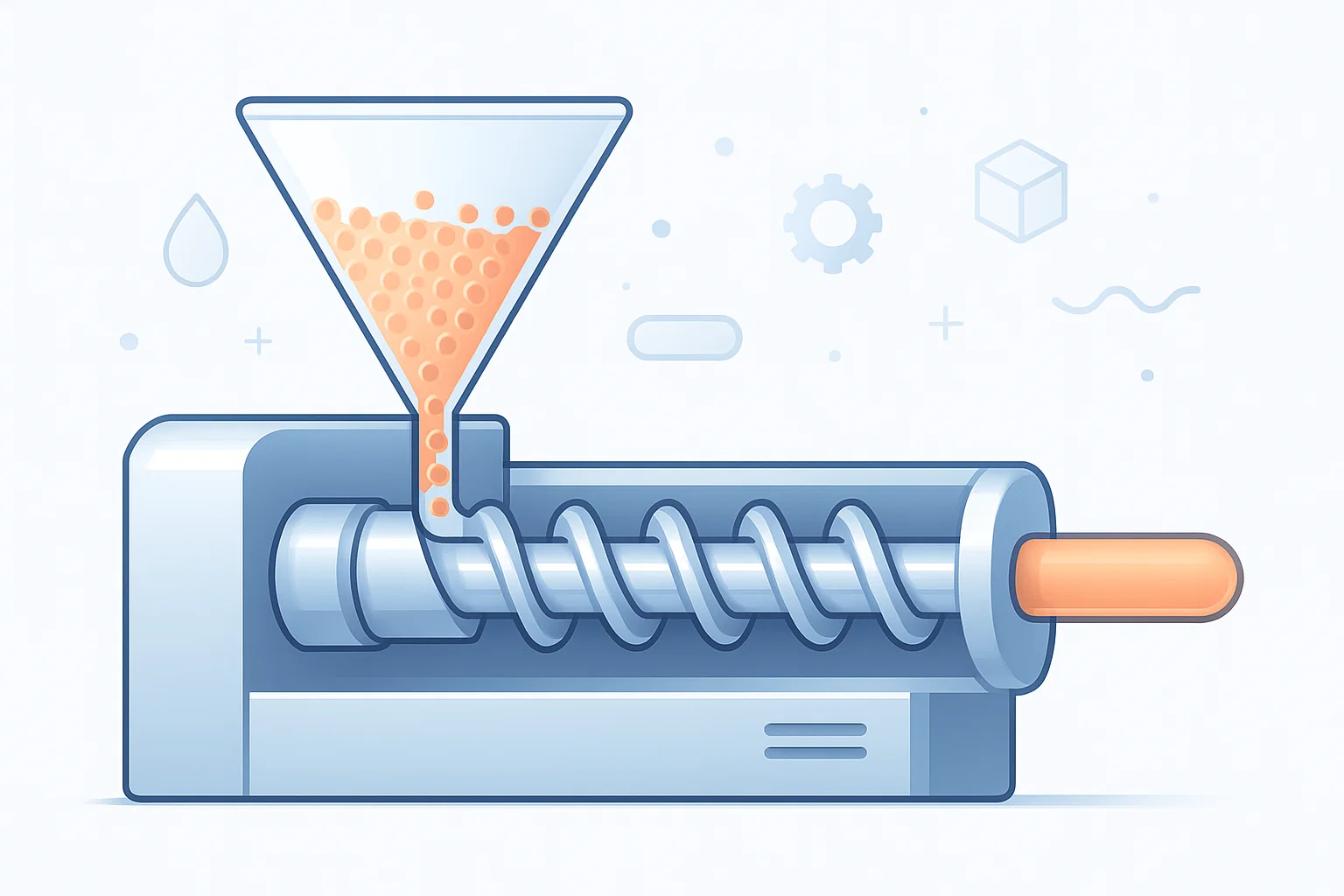

A single screw extruder is a type of extruder that utilizes a single rotating screw to process materials inside a barrel. This design is renowned for its simplicity, cost-effectiveness, and efficiency, making it a popular choice in various industries such as food processing, plastic manufacturing, pipe extrusion, and blown film production.

Due to its simple structure, high processing efficiency, and affordable cost, the single screw extruder is widely adopted for applications requiring high precision and smooth production. It is the most technically mature and frequently used type of extruder in today’s market, especially in plastic compound processing and blown film manufacturing.

Key Components of a Single Screw Extruder

Understanding the core components of a single screw extruder is essential for recognizing how it achieves such impressive results. Below are the critical systems and parts that make up this machine:

1. Extrusion System

The extrusion system is the heart of the single screw extruder, responsible for melting and plasticizing raw materials into a uniform and consistent melt. This process converts the raw materials from a solid glassy state to a molten, viscous fluid, ready for shaping and molding.

- Feeding System: Delivers the raw material to the barrel of the extruder.

- Screw: The core component that pushes, melts, and mixes the material within the barrel.

- Barrel: The chamber where the material is heated, mixed, and processed before exiting the machine.

2. Drive System

The drive system powers the screw and is critical for ensuring a steady extrusion process. The system typically consists of:

- Motor: Powers the screw’s rotation.

- Reducer: Reduces the speed of the motor to achieve the required screw speed.

- Bearings: Ensure smooth operation and support the screw’s movement.

The gearbox is a crucial component of the drive system, responsible for providing the necessary torque. The quality of the gearbox directly impacts the overall lifespan of the single screw extruder, with high-precision machining and premium components ensuring smooth, efficient operation.

3. Heating & Cooling System

The heating and cooling system regulates the temperature of the material during the extrusion process.

- Heating Unit: Ensures the material is adequately heated to the correct processing temperature.

- Cooling Unit: Maintains the required cooling during certain stages of the extrusion process.

Precise temperature control is essential for ensuring consistent product quality and efficient processing.

Applications of Single Screw Extruders

The single screw extruder is a versatile machine used across various industries, from food production to plastic manufacturing. Here are some of its primary applications:

1. Plastic Processing

In the plastic processing industry, extrusion is a key technique for shaping and forming polymer materials. Single screw extruders are integral in processing plastic resins, creating products like films, sheets, and pipes.

Different types of extruders (e.g., twin-screw extruders, multi-screw extruders) can also be used for specialized applications, but the single screw extruder remains the most popular due to its simplicity, reliability, and cost-effectiveness.

2. Food Processing

The single screw extruder is also widely used in food processing, especially for producing snacks, confectionery, and processed foods. The extrusion process helps create products that are crispy, tasty, and easy to digest.

In addition to standard food production, this technology is used to process products for specific dietary needs, such as food for children, the elderly, or those with special nutritional requirements.

3. Animal Feed Production

In animal feed production, single screw extruders help improve the texture, nutritional value, and digestibility of feed products, making them a crucial component in the livestock and pet food industries.

Advantages of Single Screw Extruders

The single screw extruder offers numerous benefits, making it a go-to solution for many manufacturing processes:

- Cost-Effective: The simple design and straightforward operation make it affordable compared to other extrusion technologies.

- High Plasticizing Efficiency: The two-stage integral design of the screw improves plasticizing efficiency, ensuring high-quality melt consistency.

- Low Energy Consumption: The extruder’s energy efficiency is one of its standout features, making it an eco-friendly choice for many industries.

- Stable Operation: With a stable screw speed, the extruder maintains consistent product quality, even under varying operational conditions.

- Long Lifespan: High-quality components and efficient design contribute to the extruder’s durability, reducing maintenance costs and downtime.

Choosing a Reliable Single Screw Extruder Manufacturer

When choosing a manufacturer for your single screw extruder, it is crucial to select a company with expertise and a proven track record in delivering high-quality, reliable extruders.

At Rumtoo Machinery, we specialize in providing top-tier single screw extruders for a wide range of industries. Our products are exported globally to over 30 countries, including Vietnam, Malaysia, Canada, Brazil, and the USA.

If you have any questions or need more information about our single screw extruders, please don’t hesitate to contact us. Our team is ready to assist you in finding the perfect solution for your production needs.