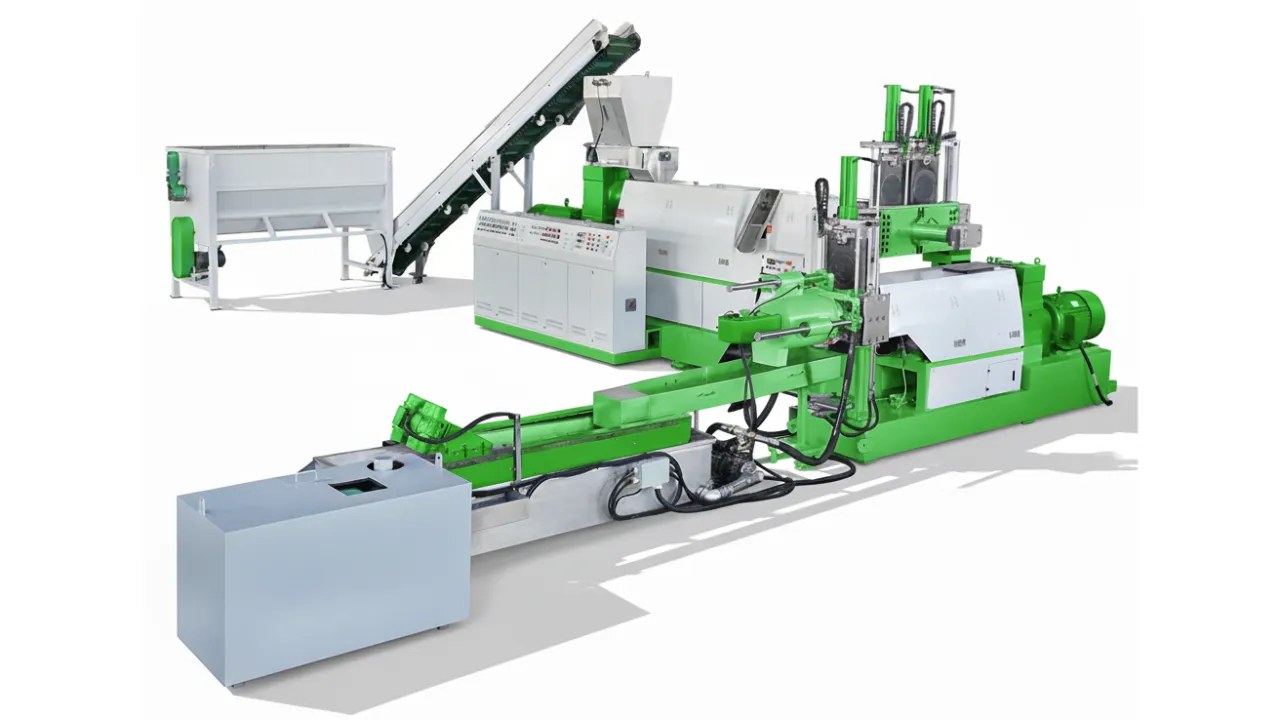

Squeezed Material Plastic Pelletizing Line

An advanced solution designed for the direct granulation of squeezed plastic films. This automated line seamlessly transforms semi-dried, compacted materials into uniform, high-quality pellets, maximizing your recycling efficiency.

Get a Custom Solution

Core Advantages of Our System

Engineered for performance and reliability, our pelletizing line offers significant benefits for your recycling operations.

Seamless Automation

From air-fed silo storage to the final pellet, the entire process is highly automated, requiring minimal labor and ensuring consistent operation.

High Output, Low Consumption

Optimized design ensures maximum throughput with reduced energy consumption, delivering a superior return on investment.

Flexible Material Handling

Effectively processes squeezed materials regardless of their exact shape or form, providing operational flexibility.

Ideal for Washed & Squeezed Films

This line is the perfect next step after a washing and squeezing-drying process, suitable for a variety of common plastic film types.

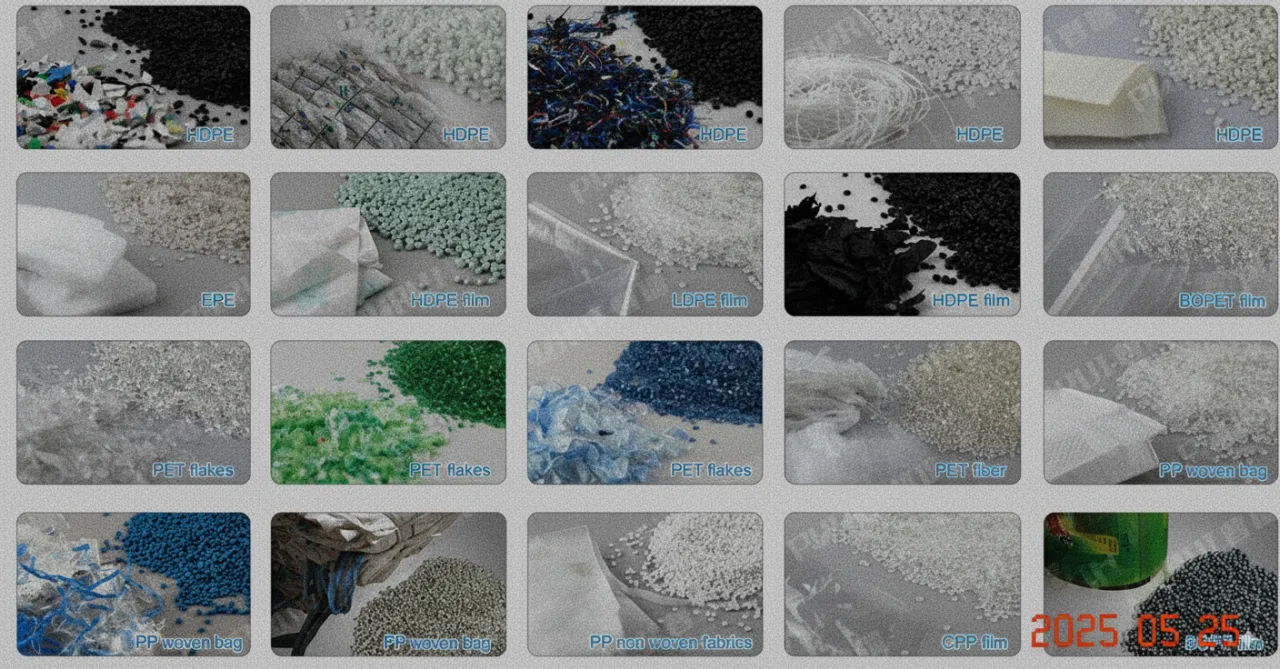

Applicable Materials

Post-washing line materials that have been processed by a squeezer dryer:

- Squeezed PE, HDPE, LDPE Film Flakes

- Squeezed PP Woven Bags

- Other squeezed soft plastics

Process Flow

The squeezed material is automatically conveyed from a squeezer machine into a storage silo, and then fed directly into the pelletizing extruder.

Advanced Technology Components

Each component is meticulously designed to ensure stability, efficiency, and the highest quality of final pellets.

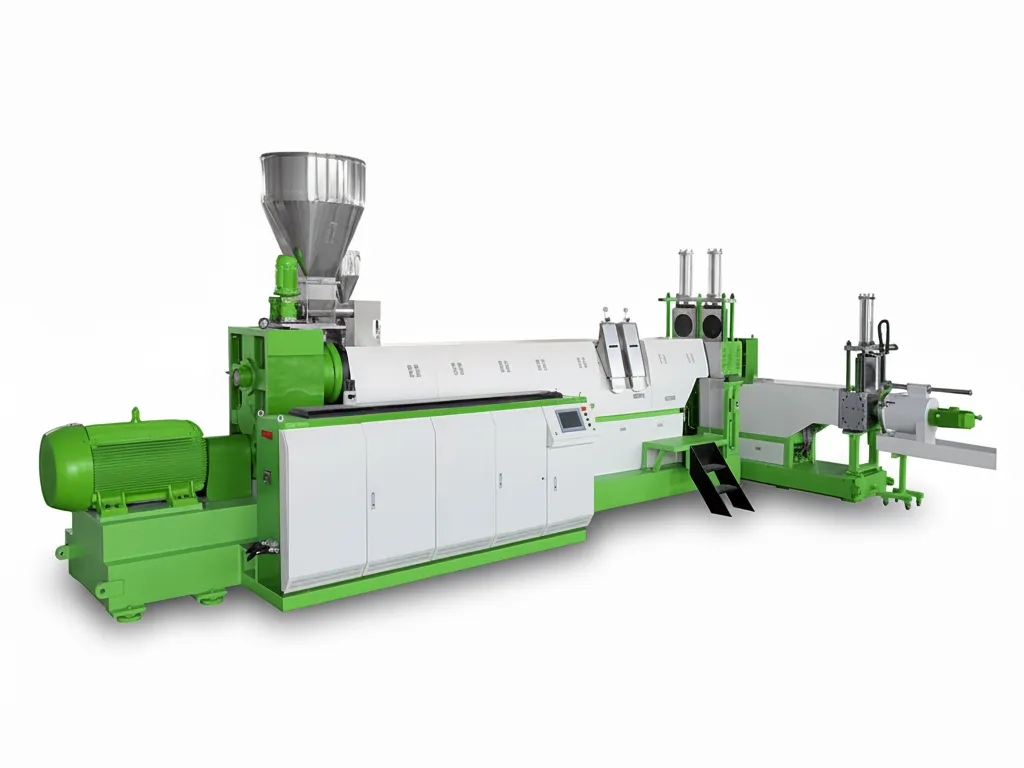

Specialized Single Screw Extruder

A robust 36D processing section gently melts and plasticizes the material. Its double-zone vacuum degassing system efficiently removes residual moisture and volatiles, perfect for materials like printed films.

Water-Ring Die-Face Cutting

This automated system ensures uniform and aesthetically pleasing pellets. The cutting speed is intelligently adjusted based on melt pressure, guaranteeing consistency and high performance.

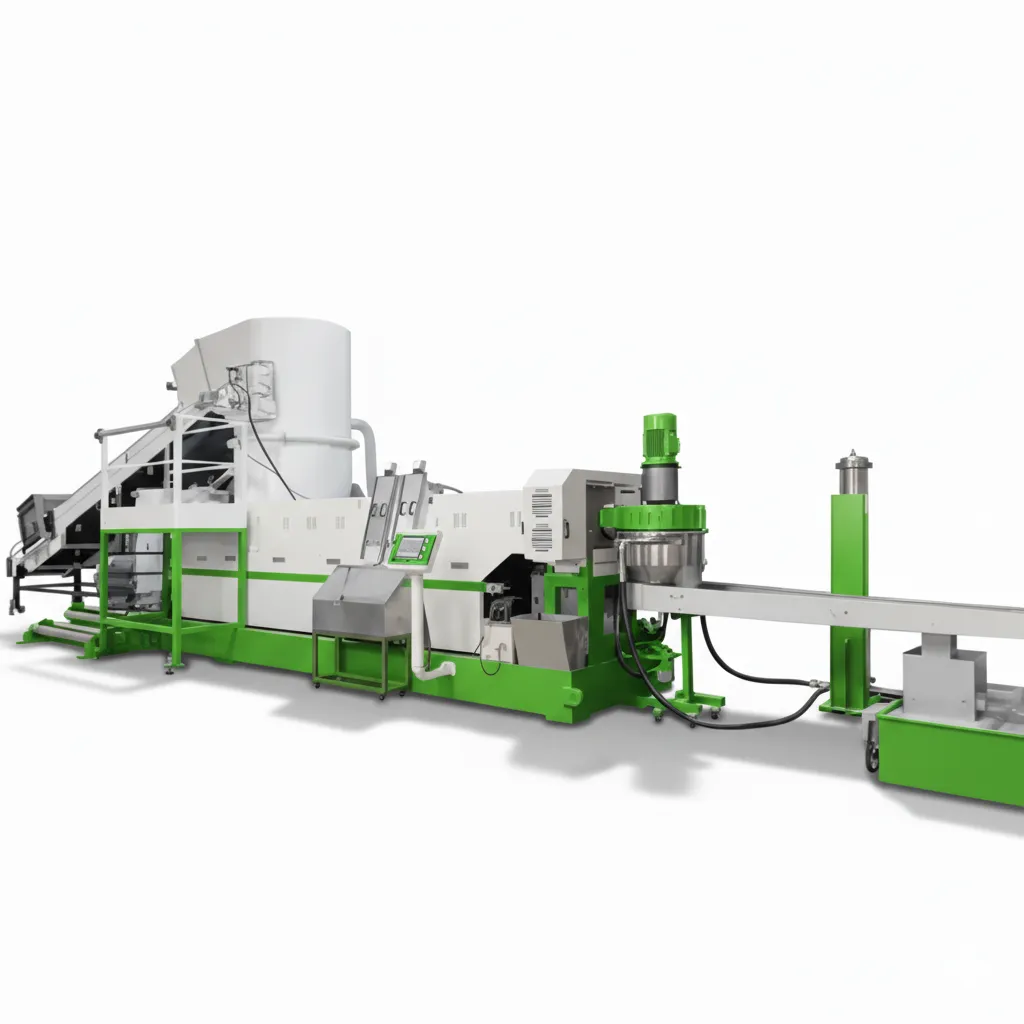

Vibration Drying & Dewatering

An advanced dewatering vibration sieve combined with centrifugal dewatering produces perfectly dried pellets while maintaining low energy consumption, preparing them for immediate packaging.

Technical Parameters

| Model | SJ140/150 | SJ160/180 | SJ180/200 | SJ200/220 |

|---|---|---|---|---|

| Output (kg/h) | ~500 | ~800 | ~1000 | 1200~1400 |

High-Quality Pellets & Global Shipping

We deliver not just a machine, but a complete solution that produces valuable end-products. Your equipment will be securely packaged and shipped to your location anywhere in the world.

Get Your Quote

Provide details about your material and required output. Our engineering team will contact you with a tailored proposal and competitive pricing within 24 hours.