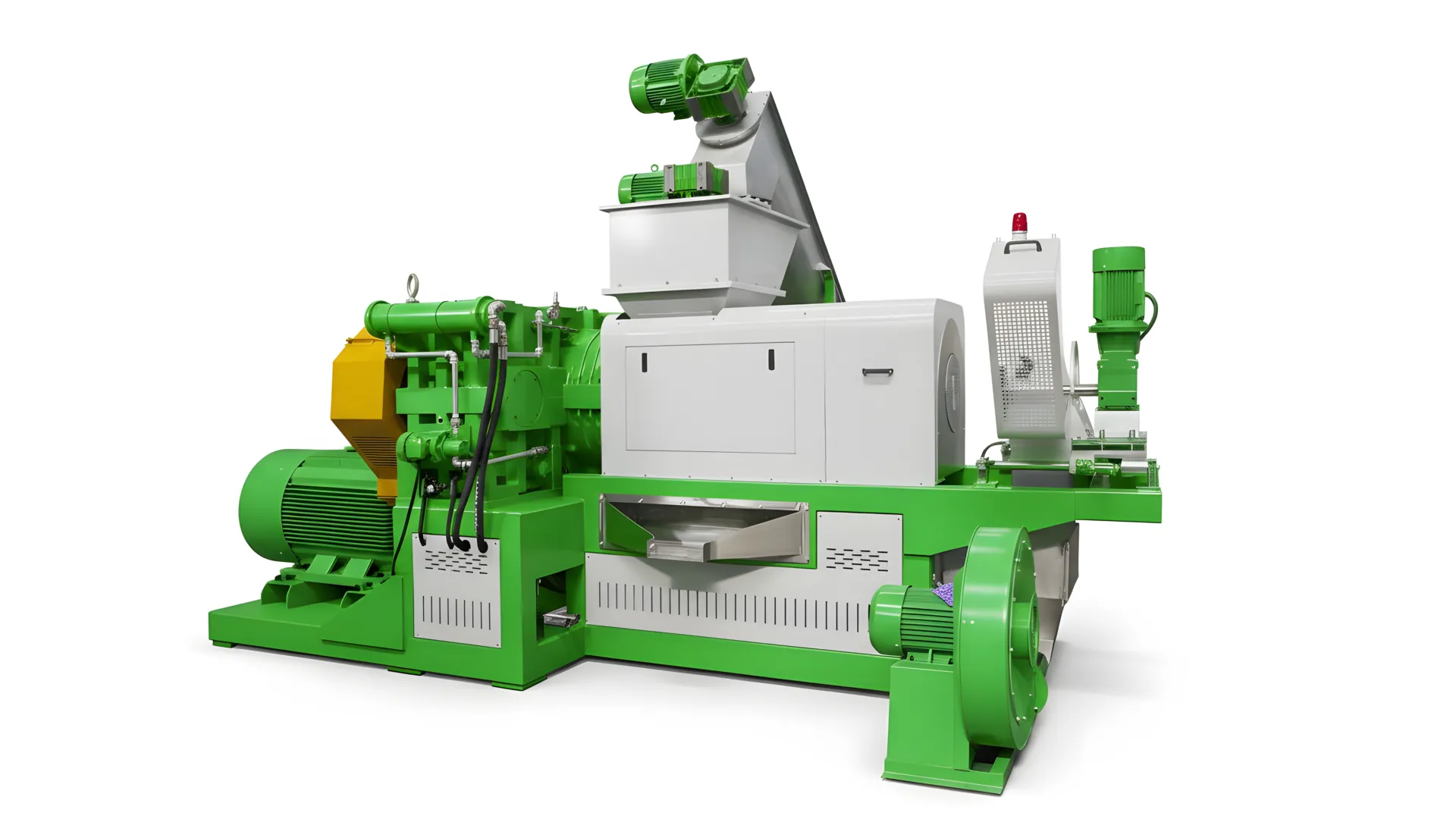

High-Efficiency Squeezer for PP/PE Film & Woven Bags

Efficiently dewater and densify washed soft plastics like films and woven bags. Our advanced squeezing technology dramatically reduces moisture content and increases material density, perfectly preparing it for the subsequent pelletizing stage and significantly boosting your production line's efficiency.

Get a Quote NowWhy Choose Our Squeezer Dryer?

We provide more than just a machine; we deliver a key solution for your soft plastics recycling process. Solve high-moisture challenges from the start, reducing costs and increasing efficiency for your recycling business.

Superior Dewatering

Reduces moisture content of washed film from 40% down to less than 3%, far superior to traditional centrifugal dryers and hot air systems.

Significant Energy Savings

Replaces energy-intensive hot air drying with mechanical squeezing, saving up to 40-50% on electricity and lowering operational costs.

Increased Material Density

Compacts light, fluffy film into high-density agglomerates, simplifying storage, transport, and ensuring stable feeding into the pelletizer.

Improved Pellet Quality

Stable feeding and extremely low moisture content prevent issues in the extruder, resulting in higher quality, more uniform recycled pellets.

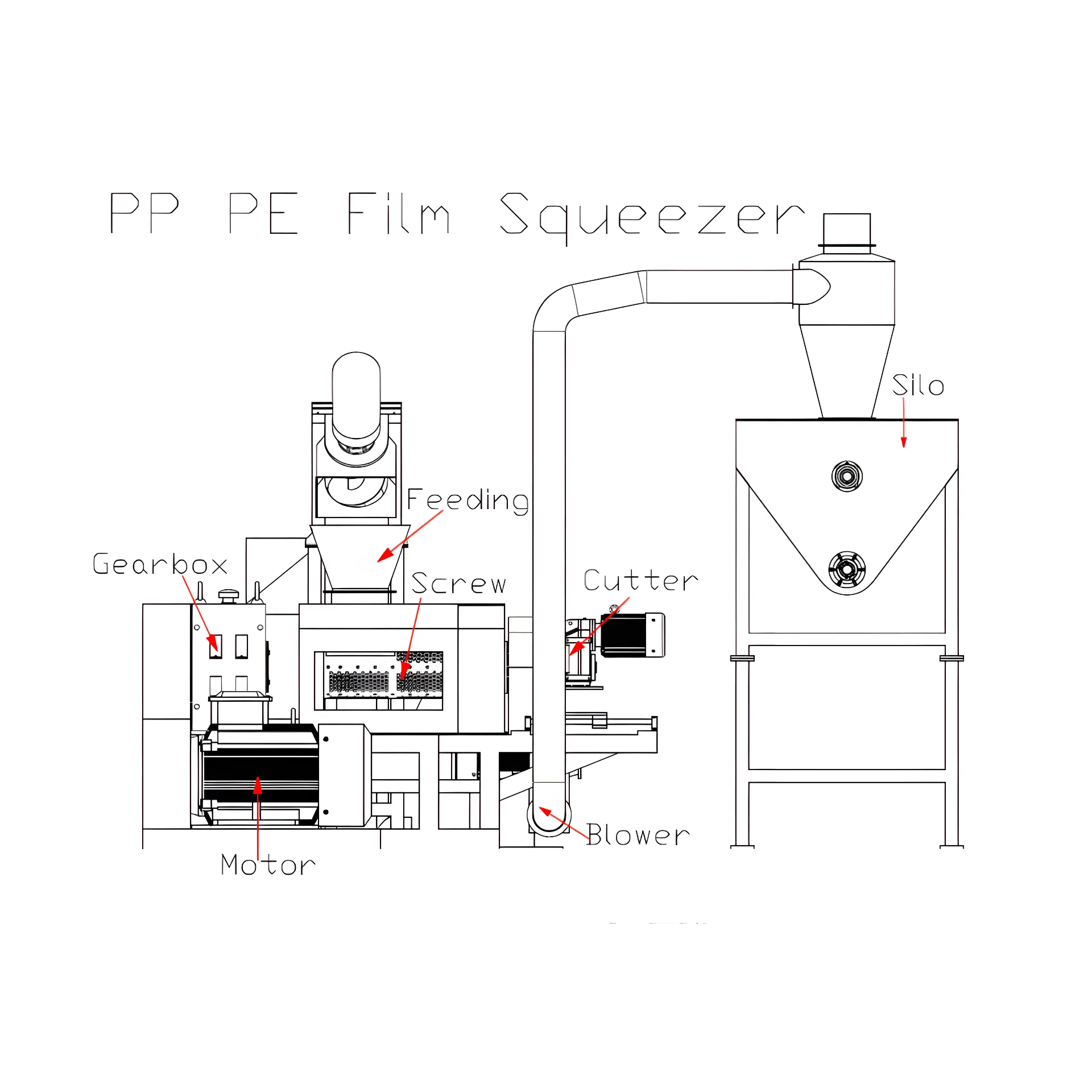

From Wet Film to Densified Flakes: The Process

Our squeezer automates the complex dewatering and densification process. Each step is engineered for maximum efficiency and output quality.

1. Feeding

Washed, wet film or woven bag scraps are uniformly fed into the squeezer's chamber via a screw conveyor.

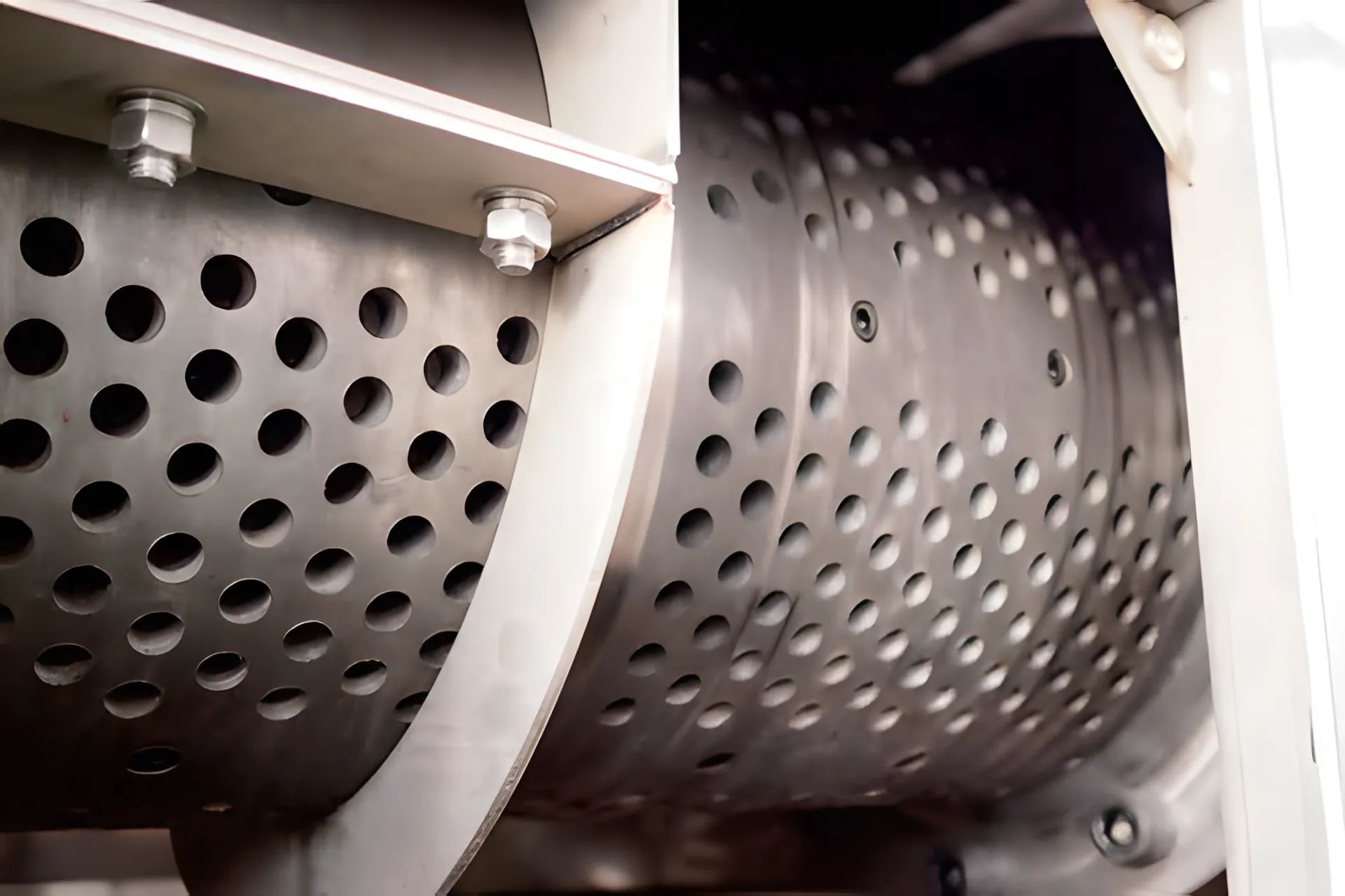

2. Squeezing & Dewatering

A specially designed screw generates immense pressure, physically forcing the majority of water out through screen filters.

3. Frictional Heating

Intense friction as the material is compressed generates heat, causing the plastic surface to semi-plasticize, which releases trapped moisture and binds the material together.

4. Cutting & Forming

The semi-plasticized material is extruded through a die and instantly cut by high-speed blades into uniform, high-density flakes, ready for the next step.

Advanced Features for Peak Performance

Every component is meticulously engineered to handle the unique challenges of soft plastic recycling, ensuring durability and high-quality output.

Heavy-Duty Wear-Resistant Screw

The screw and barrel are made from high-quality alloy steel (e.g., 38CrMoAlA) with nitriding treatment for exceptional wear and corrosion resistance, ensuring long-term stability under high pressure.

Intelligent Temperature Control

Equipped with an automatic heating and temperature control system to precisely manage the semi-plasticizing process, preventing material degradation while ensuring optimal drying.

High-Torque Gearbox

Utilizes a heavy-duty, hardened-gear gearbox that can withstand high torque, ensuring the screw operates smoothly and powerfully when processing large volumes of wet material.

PLC Smart Control

An integrated PLC control system with a user-friendly HMI allows for easy setup and monitoring of operating parameters, achieving automated and stable operation.

Anatomy of Our Squeezer

Discover the core components that make our squeezer a leader in performance, reliability, and final product quality.

Specialized Squeezing Screw & Barrel

As the heart of the machine, our screw is specifically engineered to extract water with maximum efficiency and generate the frictional heat needed for semi-plasticization.

- Optimized Screw Design: A multi-stage design ensures smooth feeding, powerful compression, and uniform plasticization.

- Efficient Drainage System: The barrel is fitted with precision drainage vents to rapidly expel the squeezed-out water.

- Durable Materials: Constructed from high-grade nitrided steel to ensure minimal wear over long-term processing of various soft plastics.

Die-Face Cutting System

This system cuts the material instantly as it is extruded from the die, creating uniform, compact flakes that are perfectly prepared for the next process.

- High-Speed Cutting Blades: Blades made from premium tool steel like SKD-11 are sharp and durable, ensuring a clean, even cut.

- Adjustable Speed: The cutting speed is inverter-controlled to adapt to different outputs and material types, achieving the ideal flake size and shape.

- Safe & Reliable: A fully enclosed design ensures operational safety and efficiently transports the cut flakes via a blower system.

Tailored Integration for Your Production Line

We understand that every recycling line is unique. Our squeezer can be seamlessly integrated into your existing process to replace traditional, inefficient drying methods.

Integrate with Your Washing Line

Place the squeezer directly at the end of your washing line, replacing both the centrifugal dryer and the hot air drying pipeline. This is a revolutionary upgrade.

- Combines dewatering and densification in one step

- Dramatically reduces footprint and equipment investment

- Achieves a fully automated process from washing to drying

Create the Ideal Feedstock for Pelletizers

The high-density, low-moisture (<3%) flakes produced by the squeezer are the perfect input for a pelletizer, bringing huge advantages to your granulation stage.

- Increases pelletizer output by 30-50%

- Ensures stable feeding, preventing "bridging" caused by fluffy material

- Reduces the pelletizer's energy consumption and improves final pellet quality

Technical Specifications: Squeezer Dryer

| Parameter | RTM-SQZ-300 | RTM-SQZ-400 | RTM-SQZ-600 | RTM-SQZ-800 |

|---|---|---|---|---|

| Output Capacity | 200-300 kg/h | 300-400 kg/h | 500-600 kg/h | 700-800 kg/h |

| Screw Diameter | 250 mm | 300 mm | 320 mm | 350 mm |

| Main Motor Power | 90 kW | 110-132 kW | 160-185 kW | 200-220 kW |

| Heating Power | 15 kW | 22 kW | 30 kW | 36 kW |

| Applicable Materials | PP/PE Film, PP Woven Bags, Agricultural Film, Packaging Film, etc. | |||

| Screw & Barrel Material | 38CrMoAlA with Nitride Treatment | |||

| Final Moisture Content | < 3% | |||

| Control System | PLC Touch Screen Smart Control | |||

Proven Performance: Gallery, Video & Applications

See our squeezer in detail, watch it in action, and discover the high-value applications for its output.

Watch Our Squeezer in Operation

Final Product & Downstream Applications

Get a Customized Solution & Quote

Ready to solve your soft plastic drying challenges for good? Fill out the form below, and our experts will contact you with a tailored proposal and quote for a squeezer solution.

Frequently Asked Questions

There are three main advantages. First, dewatering is far more thorough, reducing moisture to below 3%, whereas a centrifugal dryer often leaves 15-20% moisture. Second, it's more energy-efficient, using mechanical pressure instead of hot air. Third, it increases density by compacting fluffy film, which dramatically improves the stability and output of the subsequent pelletizing stage.

This machine is designed for washed soft plastics like PP/PE film and woven bags. The material can be fed directly from the washing tank in a very wet state; no pre-dewatering is necessary.

No. This squeezer is specifically designed for soft plastics (film, bags, etc.). Its screw design and operating principle are not suitable for dewatering PET flakes or other rigid plastics.

It helps in two major ways. First, by reducing moisture to extremely low levels, it prevents water vapor from compromising pellet quality in the extruder. Second, it transforms loose film into dense, uniform flakes, ensuring the pelletizer can be fed steadily and continuously. This significantly increases the pelletizer's output and overall efficiency.