A Buyer’s Guide to Cooling Technology for Plastic Pelletizing Machines

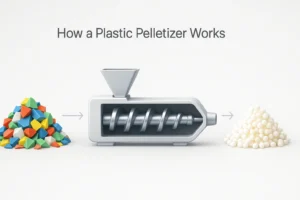

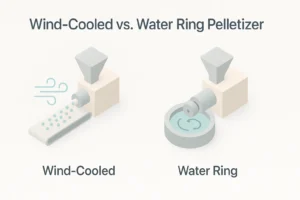

Discover why the cooling stage is critical for producing high-quality recycled plastic pellets. This guide provides a detailed analysis of water cooling (strand, ring, underwater) and air cooling systems for your plastic pelletizing machine. Understand the key differences in efficiency, cost, and application to select the ideal technology for your specific polymer and production needs, ensuring optimal pellet integrity and value.