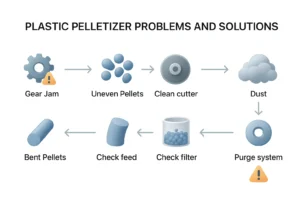

7 Common Plastic Pelletizer Problems and Solutions

By proactively managing feeding consistency, thermal control, cutting precision, and equipment integrity, pelletizer operators can minimize defects and ensure high-quality, continuous pellet production with minimal downtime.