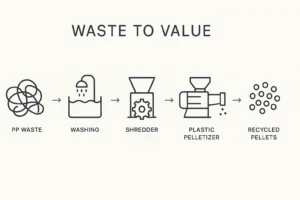

PP Raffia & Textile Regeneration: A Plastic Pelletizer Guide

Transform post-industrial and post-consumer PP raffia and textile waste into a valuable asset. This guide details the essential regeneration process, emphasizing the role of an advanced plastic pelletizer in producing high-quality pellets for demanding commercial applications and enhanced profitability.