Introduction: Unlocking Profit from the Problem of “White Pollution”

Every year, millions of tons of Expanded Polystyrene (EPS), commonly known as Styrofoam, end up in landfills. This bulky, lightweight material is an environmental headache, yet hidden within this challenge lies a significant and profitable business opportunity. As the world shifts towards a circular economy, the demand for recycled materials is at an all-time high. Processed EPS is a valuable commodity, and the entrepreneurs who can efficiently collect and densify it are positioning themselves for remarkable success.

But where do you start? What equipment do you need? And most importantly, how do you calculate your potential profit?

This guide is your comprehensive roadmap. We will walk you through every stage of launching a successful EPS foam recycling business in 2025, from securing a steady supply of raw material to selling your finished product and calculating your return on investment.

Chapter 1: Market Analysis – Understanding the Value of Your End Product

Before you process a single piece of foam, you must understand what you will be selling. Densified EPS is sold as a raw material commodity to other manufacturers.

- Your Products: You will be producing one of two products:

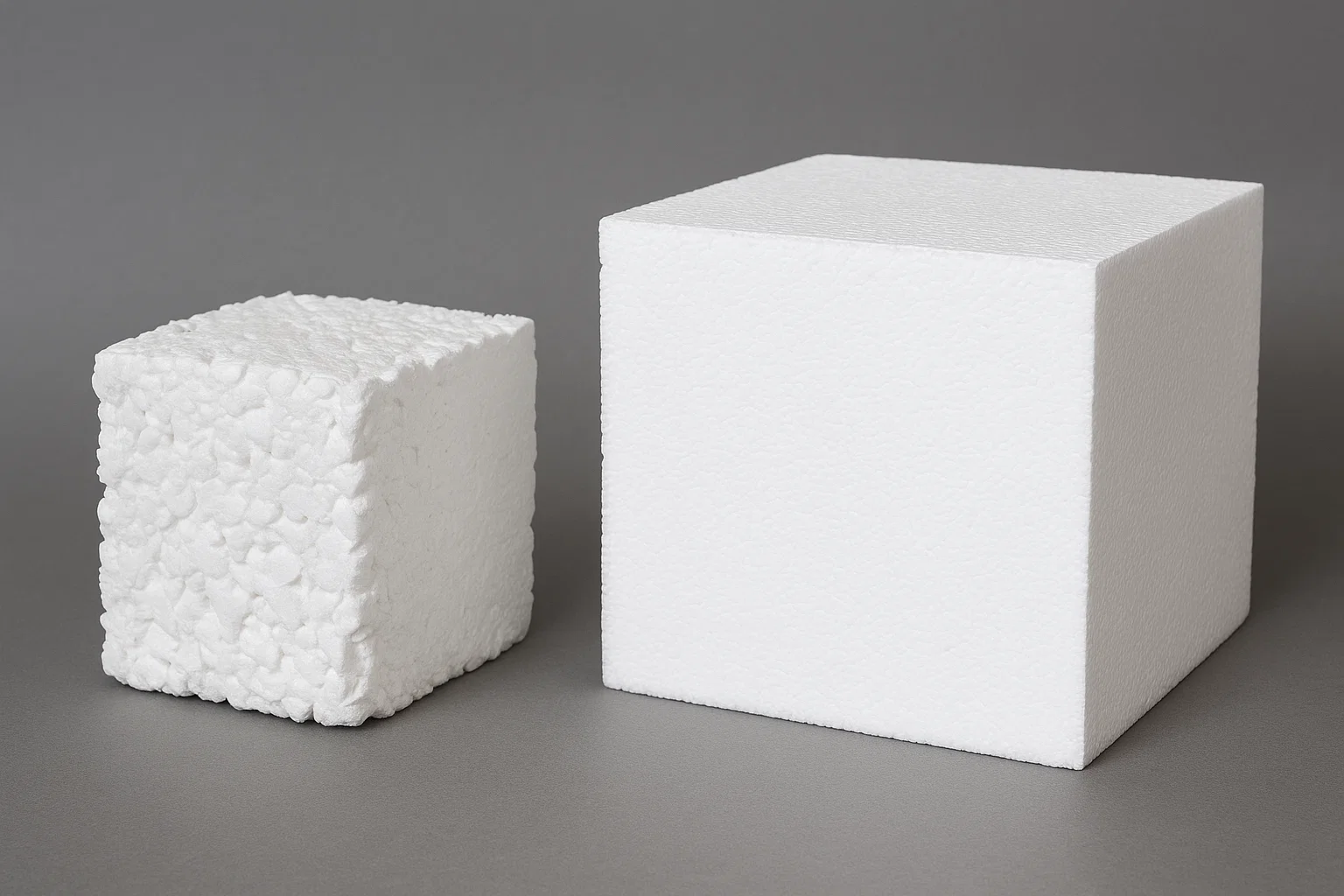

- Cold-Compressed Blocks: Dense, compacted blocks of EPS.

- Hot-Melted Ingots: Heavier, more solid, and purer ingots that look like solid plastic.

- Who Are The Buyers?Your densified material is in high demand by manufacturers who use it to create a variety of products, including:

- Picture frames and decorative architectural moldings

- Hardwood flooring and decking alternatives

- Insulation boards and panels

- Coat hangers, pens, and other injection-molded items

- What is the Market Price? (As of early 2025)Market prices fluctuate based on purity, color, density, and global demand. However, a general price range is:

- Compressed Blocks (from a compactor): $300 – $500 per metric ton.

- Melted Ingots (from a densifier): $600 – $900 per metric ton.The higher value of ingots is due to their greater density and purity, which makes them easier to transport and re-process.

Chapter 2: Feedstock Sourcing – Securing Your Raw Material

A successful recycling business is built on a consistent and low-cost supply of raw material. Here are the primary sources for waste EPS foam:

- Furniture & Appliance Retailers: This is your number one target. Large retailers generate vast amounts of clean, white EPS packaging daily. Approach them with a professional proposal: offer free and regular collection services. This saves them significant disposal fees, creating a powerful win-win partnership.

- Fishery & Seafood Markets: A huge source of EPS fish boxes. This material is often wet and may have an odor, but it is highly recyclable. A robust machine is needed to handle it, but the supply is often abundant and free for the taking.

- Logistics & Distribution Centers: E-commerce is booming, and so is the use of EPS for protecting shipped goods. Partnering with local warehouses can provide a steady stream of clean packaging foam.

- Manufacturing & Construction Sites: Industrial companies often use custom EPS packaging for components, and construction sites discard large volumes of EPS insulation panels. These are excellent sources of high-quality scrap.

Chapter 3: Equipment Selection – Your Core Investment

Choosing the right machine is the most critical decision you will make. The choice is between a Cold Compactor and a Hot-Melt Densifier.

| Feature | Cold Compactor (e.g., Rumtoo RMC Series) | Hot-Melt Densifier (e.g., Rumtoo RMD Series) |

| Technology | Physical screw compression (no heat) | Melting and extrusion |

| Volume Reduction | ~50:1 | ~90:1 (Higher density) |

| Final Product | Compressed Blocks | Dense Ingots |

| Energy Use | Low | Higher |

| Operation | Simple, no fumes, plug-and-play | Requires ventilation for fumes |

| Final Block Value | Lower ($300-$500/ton) | Higher ($600-$900/ton) |

| Best For… | Businesses with high volume and lower initial budget; focus is on reducing storage/transport costs. | Businesses aiming for maximum value per ton; space is limited; higher profit margin is the goal. |

At Rumtoo, we offer both state-of-the-art Cold Compactors and high-efficiency Hot-Melt Densifiers. We don’t push one over the other; instead, we analyze your specific business goals, feedstock type, and budget to recommend the perfect solution for you.

Chapter 4: The Business Plan – Calculating Your ROI

Let’s run a simplified Return on Investment (ROI) calculation for a startup using a Rumtoo RMD-150 Hot-Melt Densifier.

Assumptions:

- Machine processes 150 kg/hour.

- You operate 8 hours/day, 22 days/month.

- Your selling price for ingots is $750/ton.

- Your feedstock (waste foam) is free.

1. Initial Investment (Capex):

- Rumtoo RMD-150 Densifier + Installation: ~$30,000 (Example cost)

2. Monthly Operating Costs (Opex):

- Labor (1 operator): $3,000

- Electricity: $1,200

- Factory Rent & Utilities: $1,500

- Transportation & Logistics: $800

- Total Monthly Opex: $6,500

3. Monthly Revenue:

- Total Processed = 150 kg/hr * 8 hrs/day * 22 days/month = 26,400 kg = 26.4 metric tons

- Total Revenue = 26.4 tons * $750/ton = $19,800

4. Profit & Payback Period:

- Monthly Profit = $19,800 (Revenue) – $6,500 (Opex) = $13,300

- Payback Period = $30,000 (Investment) / $13,300 (Monthly Profit) = ~2.3 months

This simplified model demonstrates the powerful profitability of this venture. Even with variations in costs and prices, the business model is exceptionally robust.

Chapter 5: Operational Essentials – Setting Up for Success

- Space Requirements: A typical setup requires 50-100 square meters (500-1000 sq. ft.). This provides ample space for the machine, raw material storage (the bulky part!), and storage for your dense, finished blocks.

- Manpower: The process is highly automated. A single operator is typically sufficient to feed the machine and manage the finished product.

Conclusion: Your Partner in Profitable Recycling

The EPS foam recycling market offers a clear path to profitability while making a positive environmental impact. Success is not just about buying a machine; it’s about having a solid business plan, a reliable source of material, and the right technology partner to guide you.

Ready to draft your own EPS recycling business plan? Contact a Rumtoo expert today. We’ll not only help you choose the right machine but also provide data and insights to help you calculate your potential ROI and launch your business with confidence.