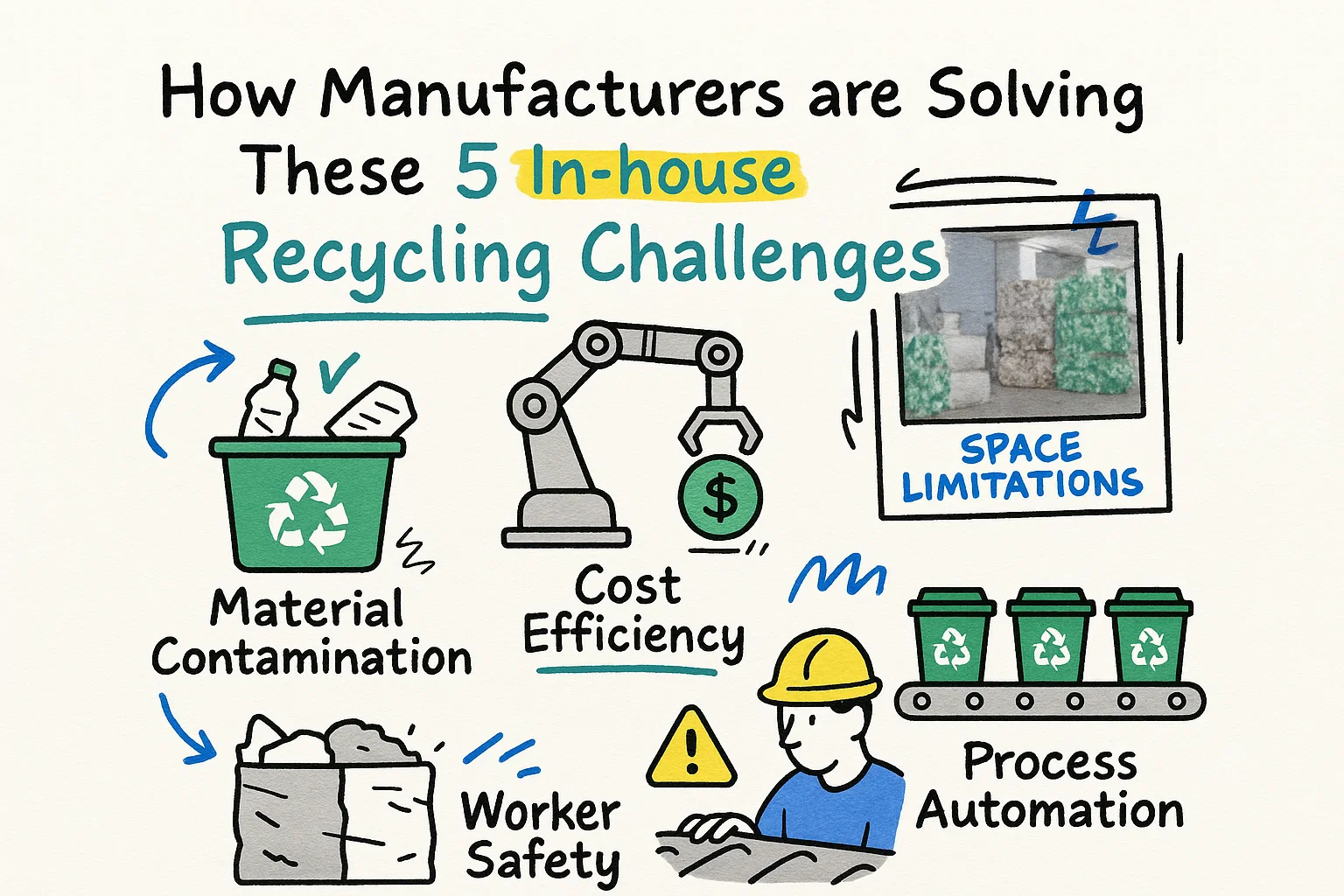

In the modern plastics industry, post-industrial waste is no longer just “trash”—it is a valuable asset waiting to be reclaimed. Whether you are dealing with extruder head waste, HDPE pipes, or soft packaging films, implementing an in-house recycling system is one of the smartest moves a manufacturer can make to cut costs and boost sustainability.

However, many manufacturers hesitate. They worry about operational complexity, inconsistent output quality, or maintenance nightmares.

At Rumtoo, we understand these concerns because we have spent years helping businesses solve them. Here is how modern technology is tackling the top 5 challenges of in-house recycling—and why Rumtoo machines are the competitive edge you need.

Challenge 1: “We Don’t Have the Skilled Labor to Run Complex Machinery”

The Pain Point: Factory managers often fear that adding a recycling line means hiring expensive specialists or pulling operators away from primary production lines. If a machine is too complex, operator error can lead to downtime or accidents.

The Rumtoo Solution: Automation and Simplicity Modern recycling shouldn’t require a PhD in engineering. We prioritize user-friendly designs and intelligent automation.

- Intuitive Controls: Our systems feature simplified control panels (PLC) that allow operators to start, stop, and monitor the machine with minimal training.

- Automated Feeding: Whether you are using a Soft Material Single Shaft Shredder or a heavy-duty model, features like auto-reverse on jamming and smart hopper designs reduce the need for constant manual intervention. Your team can focus on production, while the machine handles the waste.

Challenge 2: “Recycled Material Ruins Our Product Quality”

The Pain Point: The biggest fear in in-house recycling is introducing “bad blood” into the production line. If the recycled pellets or flakes are non-uniform, dusty, or degraded by heat, they can cause defects in the final product.

The Rumtoo Solution: Precision Size Reduction Quality starts with the cut. Inconsistent shredding leads to inconsistent melting.

- Uniform Particle Size: Our Single Shaft Shredders utilize precise screen alignment and high-quality rotors to ensure uniform output size.

- Targeted Processing: We don’t use a “one-size-fits-all” approach. Whether you need a Rigid Plastics Shredder for hard lumps or a specialized machine for Plastic Film, our equipment is calibrated to the specific material density. This minimizes dust and heat generation, preserving the physical properties of the plastic so it can be reintroduced directly into your production line without compromising quality.

Challenge 3: “We Simply Don’t Have the Floor Space”

The Pain Point: Real estate on a production floor is expensive. Traditional recycling lines—consisting of a conveyor, shredder, conveyor, granulator, and blower—can take up a massive footprint that many factories simply cannot spare.

The Rumtoo Solution: Compact & Integrated Designs Efficiency is about doing more with less space.

- Integration: For facilities with tight layouts, we recommend our Integrated Shredder and Granulator Machines. By combining two steps into a single compact unit, you save significant floor space while maintaining high throughput.

- Smart Layouts: Even for bulky items like large pipes, our High-Performance Horizontal Pipe Shredder is designed with a low profile and efficient footprint in mind, allowing you to process long waste items without disrupting traffic flow in your factory.

Challenge 4: “Maintenance is Too Expensive and Time-Consuming”

The Pain Point: Downtime kills profitability. If changing knives takes half a day, or if residue cleanup is impossible, the machine eventually becomes a neglected heap of metal in the corner of the factory.

The Rumtoo Solution: The “Easy Access” Philosophy We build machines for the people who maintain them.

- Fast Maintenance: Features like our Single Shaft Shredders with Drawer designs allow for quick access to the internal screen and rotor. This means screen changes and cleaning can be done in minutes, not hours.

- Durability: We use shear-type double shaft technology and wear-resistant materials for our blades. Whether processing rubber tires or heavy-duty HDPE, Rumtoo components are built to last longer between changes, significantly lowering your operational costs (OPEX).

Challenge 5: “The Energy Costs Eat Up the Savings”

The Pain Point: If the cost of electricity to run the shredder exceeds the value of the reclaimed material, the ROI vanishes. Older, inefficient motors are notorious energy vampires.

The Rumtoo Solution: Energy-Efficient Engineering

- Optimized Torque: Our machines, from the Fixed Bucket Single Shaft Shredder to our powerful double-shaft models, utilize high-torque, low-speed technology. This delivers immense cutting power to break down hard materials without the energy spikes associated with traditional high-speed crushers.

- Smart Power Usage: By matching the motor power precisely to the application (e.g., specific setups for Extruder Head Waste vs. light films), we ensure you only use the energy required for the job.

Why Choose Rumtoo?

Buying a recycling machine is easy; finding a solution that fits your specific production flow is harder.

At Rumtoo, we don’t just sell standard specs. We look at your waste stream—whether it’s heavy purge lumps, long pipes, or delicate films—and we match you with the exact Powerful Shredder Machine required. We combine heavy-duty construction with intelligent design to ensure your in-house recycling turns waste into direct profit.

Ready to stop wasting money on waste?

Let’s evaluate your current recycling needs. Contact Rumtoo today for a consultation on the ideal shredding solution for your factory.