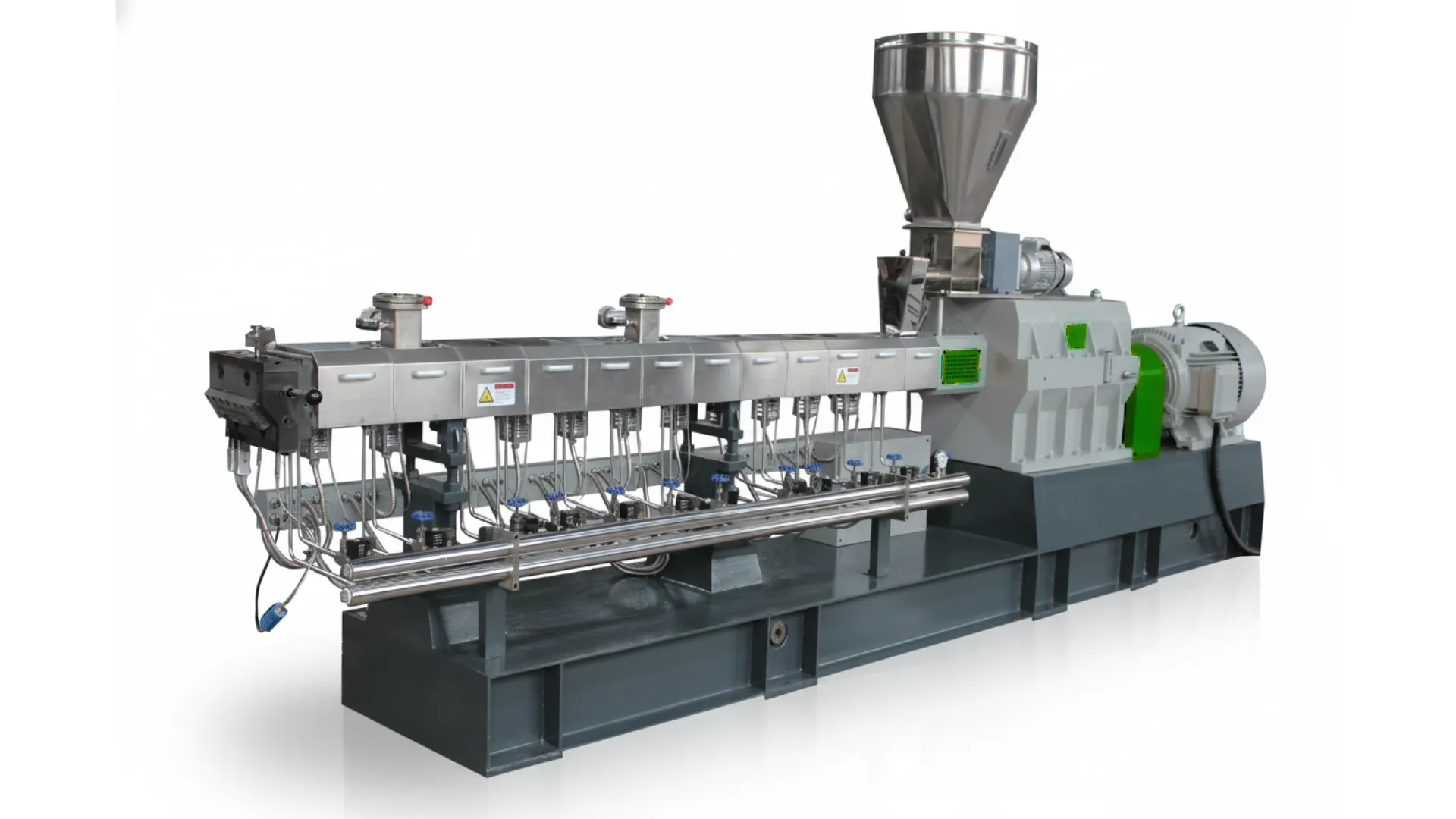

Twin Screw Extruders – Advanced Plastic Compounding & Recycling Solutions

Engineered for manufacturers who demand superior mixing, compounding, and pelletizing performance. Our twin screw extruders deliver consistent output quality, exceptional process control, and unmatched reliability for plastic recycling and polymer processing applications worldwide.

Get Custom Solution & QuoteHow Twin Screw Extruders Work

Material Feeding

Plastic materials are fed into the twin screw barrel through precision gravimetric or volumetric feeders, ensuring consistent flow rates and optimal processing conditions.

Co-Rotating Screws Mix & Melt

Two intermeshing screws rotate in the same direction, creating intense shear and distributive mixing. The modular screw design allows customization for specific materials and applications.

Compounding & Homogenization

Advanced screw configurations ensure thorough mixing of additives, fillers, and reinforcements, achieving molecular-level homogeneity with precise temperature control throughout multiple barrel zones.

Degassing & Purification

Vacuum vents remove moisture, volatiles, and trapped air from the polymer melt, improving final product quality and preventing defects in downstream processes.

Die Formation & Pelletizing

The homogeneous melt exits through a strand die or underwater pelletizing system, producing uniform pellets ready for manufacturing or resale.

Cooling & Collection

Pellets are rapidly cooled in water baths or air cooling systems, then dried and conveyed to storage silos, maintaining consistent quality throughout the production cycle.

Core Advantages of Our Twin Screw Extruders

Superior Mixing Efficiency

Co-rotating twin screws deliver distributive and dispersive mixing that single-screw extruders cannot match, ideal for complex formulations and recycled materials with contamination.

Flexible Process Control

Modular screw configuration and independent barrel zone temperature control enable processing of diverse materials—from virgin polymers to heavily contaminated post-consumer waste.

Self-Wiping Technology

Intermeshing screw design prevents material buildup and degradation, reducing downtime for cleaning and eliminating cross-contamination between batches.

High Throughput Capacity

Process 200–2,000 kg/hr depending on model, with consistent output quality even at maximum production rates.

Effective Degassing

Multiple vacuum ports efficiently remove moisture and volatiles from recycled plastics, improving pellet quality and downstream processability.

Energy-Efficient Operation

Advanced drive systems and optimized screw geometry reduce specific energy consumption by up to 20% compared to conventional designs.

Turning Plastic Processing Challenges Into Opportunities

Common Industry Challenges

- Inconsistent melt quality from recycled feedstock with varying contamination levels

- Poor mixing of additives and fillers leading to product defects and customer complaints

- Excessive material degradation from prolonged residence time in traditional extruders

- High moisture content in recycled plastics causing porosity and weak mechanical properties

- Frequent production stops for screw cleaning and material changeovers

- Limited flexibility to process different polymer types on the same line

How Our Extruders Solve This

- Advanced twin-screw mixing technology homogenizes even heavily contaminated recycled materials

- Distributive and dispersive mixing zones ensure uniform additive distribution throughout the melt

- Self-wiping screw design and optimized residence time minimize thermal degradation

- Multi-stage vacuum degassing removes up to 2% moisture without pre-drying, reducing operating costs

- Quick-change screw modules enable rapid material changeovers in under 30 minutes

- Versatile barrel and screw configurations process PE, PP, PS, PET, ABS, and specialty polymers

See Our Twin Screw Extruders in Action

Watch how our twin screw extruders transform recycled plastic waste into high-quality pellets with consistent performance and reliability.

Applications & Industries

Plastic Recycling

Process post-consumer and post-industrial waste including PE, PP, PS, PET, and mixed plastics into high-quality recycled pellets for remanufacturing.

Masterbatch Production

Create color and additive masterbatches with precise pigment dispersion and consistent color matching for demanding applications.

Compounding & Blending

Formulate custom polymer compounds with fillers, reinforcements, flame retardants, and performance additives for specialized applications.

Biodegradable Plastics

Process PLA, PHA, starch-based polymers, and other bioplastics with gentle handling and precise temperature control.

Engineering Plastics

Compound high-performance materials like nylon, PC, PEEK, and specialty polymers with glass fibers or carbon reinforcements.

Wood-Plastic Composites

Mix wood flour or natural fibers with thermoplastics to produce WPC for decking, fencing, and construction applications.

Technical Specifications

| Model | Screw Diameter (mm) | L/D Ratio | Throughput (kg/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| TSE-35 | 35 | 40:1 | 50-150 | 37 | 2,500 |

| TSE-50 | 50 | 40:1 | 100-300 | 75 | 4,200 |

| TSE-65 | 65 | 40:1 | 200-500 | 132 | 6,800 |

| TSE-75 | 75 | 40:1 | 300-800 | 185 | 9,500 |

| TSE-95 | 95 | 40:1 | 500-1,500 | 315 | 15,000 |

| TSE-135 | 135 | 40:1 | 1,000-2,500 | 560 | 28,000 |

*Specifications may vary based on material type, screw configuration, and downstream equipment. Contact us for detailed configuration recommendations.

Why Choose Twin Screw Over Single Screw Extruders?

| Feature | Our Twin Screw Extruders | Traditional Single Screw |

|---|---|---|

| Mixing Quality | ✓ Excellent distributive & dispersive mixing | ✗ Limited mixing capability |

| Material Versatility | ✓ Handles contaminated recycled materials | ✗ Requires cleaner feedstock |

| Degassing Efficiency | ✓ Multi-stage vacuum degassing | ✗ Limited degassing capability |

| Self-Cleaning | ✓ Self-wiping screw design | ✗ Requires frequent manual cleaning |

| Process Flexibility | ✓ Modular screw configuration | ✗ Fixed screw design |

| Residence Time Control | ✓ Short, controlled residence time | ✗ Longer residence time, higher degradation risk |

| Filler/Additive Incorporation | ✓ Up to 70% filler loading | ✗ Limited to 30-40% filler content |

Frequently Asked Questions

What Our Customers Say

“We upgraded from a single screw system to this twin screw extruder and immediately saw a 40% increase in throughput with better pellet quality. The self-cleaning design reduced our downtime by half. Best investment we’ve made in our recycling operation.”

“The modular screw configuration lets us process everything from clean HDPE to contaminated mixed plastics without changing equipment. The degassing system handles high-moisture feedstock that would clog our old extruder. Outstanding flexibility and reliability.”

“Technical support and training were exceptional. The PLC control system is intuitive, and the energy efficiency has reduced our operating costs by 25%. We’re now processing 500 kg/hr of recycled PET with consistent quality for our bottle-to-bottle applications.”

Ready to Transform Your Plastic Processing Operation?

Get a customized solution and detailed quote for your specific application. Our technical experts will help you select the optimal configuration for your materials and production requirements.