Single screw extruders are cost-effective workhorses for stable, single-material processes like film, sheet, and many recycling granulation applications.

Twin screw extruders excel at mixing, compounding, and processing variability. They deliver tighter quality control, better dispersion of fillers/additives, and broader recipe flexibility.

Buying takeaway:

- If your plant needs consistent pellets from mixed or additive-rich streams, a twin screw line from Rumtoo will typically reduce rework and stabilize output KPIs.

- If your inputs are consistent and budgets are tight, Rumtoo’s single screw packages provide the best capex-to-output value.

What Buyers Really Need to Know

- Throughput and quality goals come first. Choose the screw system that meets your target kg/h at your desired melt quality and energy per kg.

- Input variability drives risk. More contaminants, additives, or recipe changes point toward twin screw.

- Lifetime cost beats sticker price. Screw wear, energy, downtime, and rework rates often outweigh initial capex differences within 12–24 months.

Quick Comparison: Twin Screw vs. Single Screw

| Criteria | Twin Screw Extruder | Single Screw Extruder |

|---|---|---|

| Best for | Compounding, masterbatch, mixed or variable feedstocks, precise dispersion | Stable, single-material extrusion and recycling granulation |

| Mixing/dispersion | Excellent. Intermeshing elements create intensive shear and uniformity | Good for simple melts. Limited dispersion of complex additives |

| Recipe flexibility | High. Modular elements enable fast reconfiguration | Moderate. Optimized for narrow process windows |

| Energy profile | Often lower per kg thanks to efficient internal friction and venting | Can be higher for difficult melts due to barrel heating reliance |

| Quality consistency | Very high. Better devolatilization and dispersion stabilize IV/MFI | High for simple formulations with clean feed |

| Capex | Higher | Lower |

| Maintenance | More complex, but self-wiping reduces clean-down time between runs | Simpler. Lower routine maintenance burden |

- Handles mixed, additive-rich, and variable streams with confidence.

- Excellent dispersion and devolatilization for demanding specifications.

- Modular screw design supports frequent recipe changes and new SKUs.

- Lower capex and simpler operation for stable, clean feedstocks.

- Excellent kg/h performance on fixed recipes.

- Lower routine maintenance and easier troubleshooting for operators.

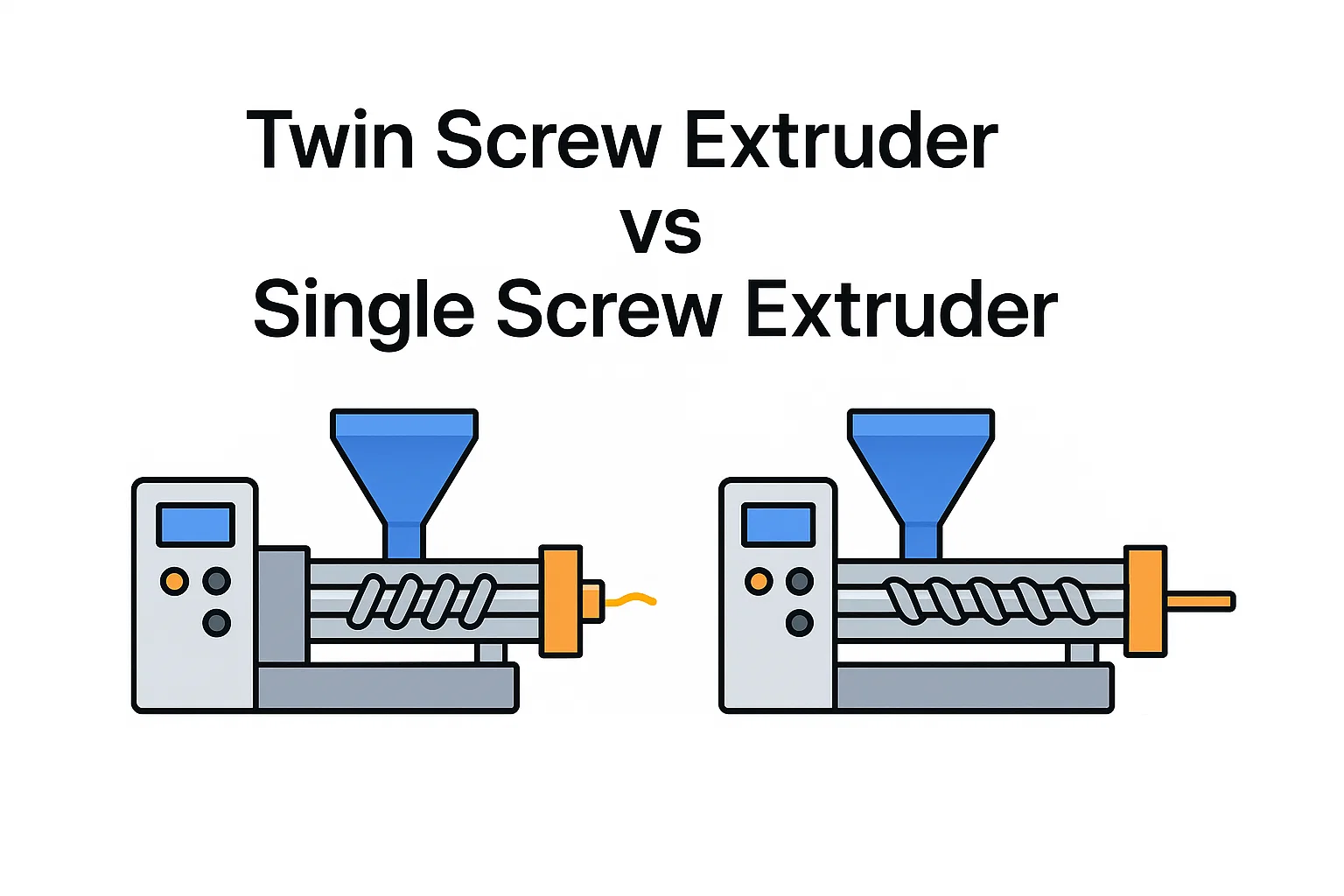

How Each Extruder Works

A single rotating screw conveys, melts, and pressurizes material through a die. It’s straightforward, reliable, and efficient for clean, consistent inputs. Ideal for:

- Sheet and film extrusion lines

- HDPE/PP/PE pelletizing from stable post-industrial streams

- Pipe and profile extrusion where recipes rarely change

Two co-rotating, often intermeshing screws generate controlled shear and mixing. Modular elements (conveying, kneading, mixing, venting) are configured for your recipe and goals. Best when you need:

- Uniform dispersion of fillers, pigments, and additives

- Devolatilization for moisture and residual solvents

- Stable output with variable or multi-component feedstocks

Key Buyer Considerations

1) Input Material and Variability

- Mostly single resin, low contamination: Single screw is cost-effective and robust.

- Mixed streams, fillers, color or additive packages: Twin screw improves dispersion and consistency.

2) Quality Targets

- Tight MFI/IV control, color uniformity, and mechanical property repeatability favor twin screw.

- For standard granulation with basic specs, single screw meets targets at lower cost.

3) Throughput and Energy

- Twin screw lines typically maintain high throughput at lower melt temperature, thanks to effective internal shear and venting.

- Single screw lines deliver excellent kg/h on clean, predictable feed with minimal complexity.

4) Changeovers and Flexibility

- Twin screw’s modular sections reduce changeover time when switching recipes or adding new SKUs.

- Single screw excels when the recipe is fixed and you want the simplest operation.

5) Lifetime Cost

- Twin screw: Higher capex, lower rework, better quality stability, faster payback with demanding recipes.

- Single screw: Lower capex, minimal maintenance, excellent TCO for stable products.

Recommended Applications

Twin Screw Extruder

- Masterbatch: filler, color, additive

- Reinforced compounds: glass fiber, flame retardant grades

- Reactive or devolatilizing processes

- High-filler PP/PE up to 70–75% CaCO3

- Engineering resins requiring precise thermal control

Single Screw Extruder

- Sheet and film: PET, PP, PS, PVC, PC

- Pipe and profile: PVC, PP-R, PE variants

- Recycling granulation: PP/PE film flakes and bottle regrind with consistent quality targets

Why Rumtoo

Process-First Engineering

We start with your feedstock, target properties, and downstream requirements, then specify the screw design, L/D, venting, and thermal profile that deliver stable KPIs.

Modular Screw and Barrel Systems

- Quickly reconfigure kneading and mixing blocks to support new products

- Side feeders and liquid injection for fillers and additives

- Vacuum vents for moisture and volatiles control

Quality and Uptime by Design

- Self-wiping twin screw geometries shorten clean-downs

- Wear-resistant metallurgy on critical elements extends service life

- Closed-loop controls stabilize melt pressure, temperature, and throughput

Proven Value in Recycling

Whether your priority is maximum yield from LDPE film or tight IV control in PET, Rumtoo lines are tuned to reduce energy per kg and minimize off-spec.

Explore Rumtoo Twin Screw Extruders »

Explore Rumtoo Single Screw Extruders »

How to Choose: A Simple Decision Flow

Yes → Start with Twin Screw

No → Go to step 2

Yes → Choose Twin Screw

No → Go to step 3

Yes → Single Screw is the right starting point.

No → Evaluate lifecycle ROI – with demanding products, Twin Screw often wins.

Frequently Asked Questions

Not necessarily. For complex recipes, lower rework and improved devolatilization can reduce energy and scrap costs per kg.

Yes, but dispersion and quality uniformity may vary. If changes are frequent, twin screw offers better stability.

Single screw is simpler. Twin screw has more parts but self-wiping reduces downtime between runs, and Rumtoo’s wear packages extend overhaul intervals.

Specifications We Configure With You

- Screw diameter and L/D

- Torque class and gearbox

- Heating and cooling zones

- Venting and vacuum systems

- Side feeder and liquid dosing

- Melt filtration and pelletizing options

- Control architecture and data logging

Ready to match the right extruder to your line?

Share your feed analysis, target throughput, and quality KPIs. Rumtoo will engineer a system that hits your numbers with room to grow.