The Game-Changer in Plastic Film Recycling: What is Densifying and Why You Need It

If you’re in the plastics recycling business, you know the struggle: PP/PE film is light, fluffy, and often wet. It clogs machinery, costs a fortune to transport, and makes producing high-quality pellets a constant challenge. But what if there was a single step that could solve these problems? That’s where densifying comes in.

Let’s break down exactly what densifying is and how it transforms your recycling operation from a logistical headache into a streamlined, profitable powerhouse.

So, What Exactly is “Densifying”?

Think of it as turning a giant, loose pile of feathers into a small, heavy brick. In PP/PE film recycling, densifying is the process of transforming washed plastic film into dense, dry, and uniform granules or clumps.

This is achieved by applying heat and mechanical pressure. A specialized machine, like a screw squeezer or compactor, heats and presses the cleaned film, squeezing out water and compressing the material. The result is a dramatic increase in bulk density—often from a fluffy 30-50 kg/m³ to a solid 350–410 kg/m³. At the same time, moisture content plummets from as high as 40% down to an impressive 3% or less.

The Core Advantages: How Densifying Supercharges Your Workflow

Integrating a densifying step isn’t just an improvement; it’s a fundamental upgrade to your entire process. Here’s how it directly benefits your bottom line and operational efficiency.

Slash Transportation & Storage Costs

By drastically increasing the material’s density, you can fit up to 10 times more material into a single truck or storage container. This means fewer trips, lower fuel costs, and a smaller storage footprint—direct savings that add up fast.

Boost Downstream Efficiency

Feeding light, airy film into a pelletizer is inconsistent and prone to jamming. Dense, uniform granules flow smoothly and predictably, ensuring a stable feed rate. This maximizes the output of your pelletizing line and dramatically reduces downtime and wear on your equipment.

Enhance Recycled Pellet Quality

Moisture is the enemy of high-quality recycled plastic. By effectively dewatering the film, densifying eliminates issues like bubbles and “silver streaks” in the final pellets. The result is a premium, more valuable product that commands a higher price on the market.

Before vs. After: The Real-World Impact of Densifying

The difference between a recycling line with and without a densifier is night and day. Here’s a clear comparison:

Recycling Without Densifying

- High Costs: Sky-high shipping and storage fees due to low-density material.

- Inefficient Feeding: Constant extruder jams and inconsistent throughput.

- Energy Waste: Requires massive amounts of energy for a separate, slow drying process.

- Poor Pellet Quality: Final products are often compromised by high moisture content.

- Operational Headaches: Material is difficult to handle, store, and process automatically.

Recycling With Densifying

- Cost Savings: Dramatically reduced logistics and storage expenses.

- Smooth Operations: Stable, continuous feeding into the pelletizer for maximum uptime.

- Energy Efficiency: Combines dewatering and compacting, saving on energy costs.

- Premium Pellet Quality: Produces dry, high-quality pellets ready for manufacturing.

- Streamlined Workflow: Creates a manageable, valuable feedstock that simplifies the entire process.

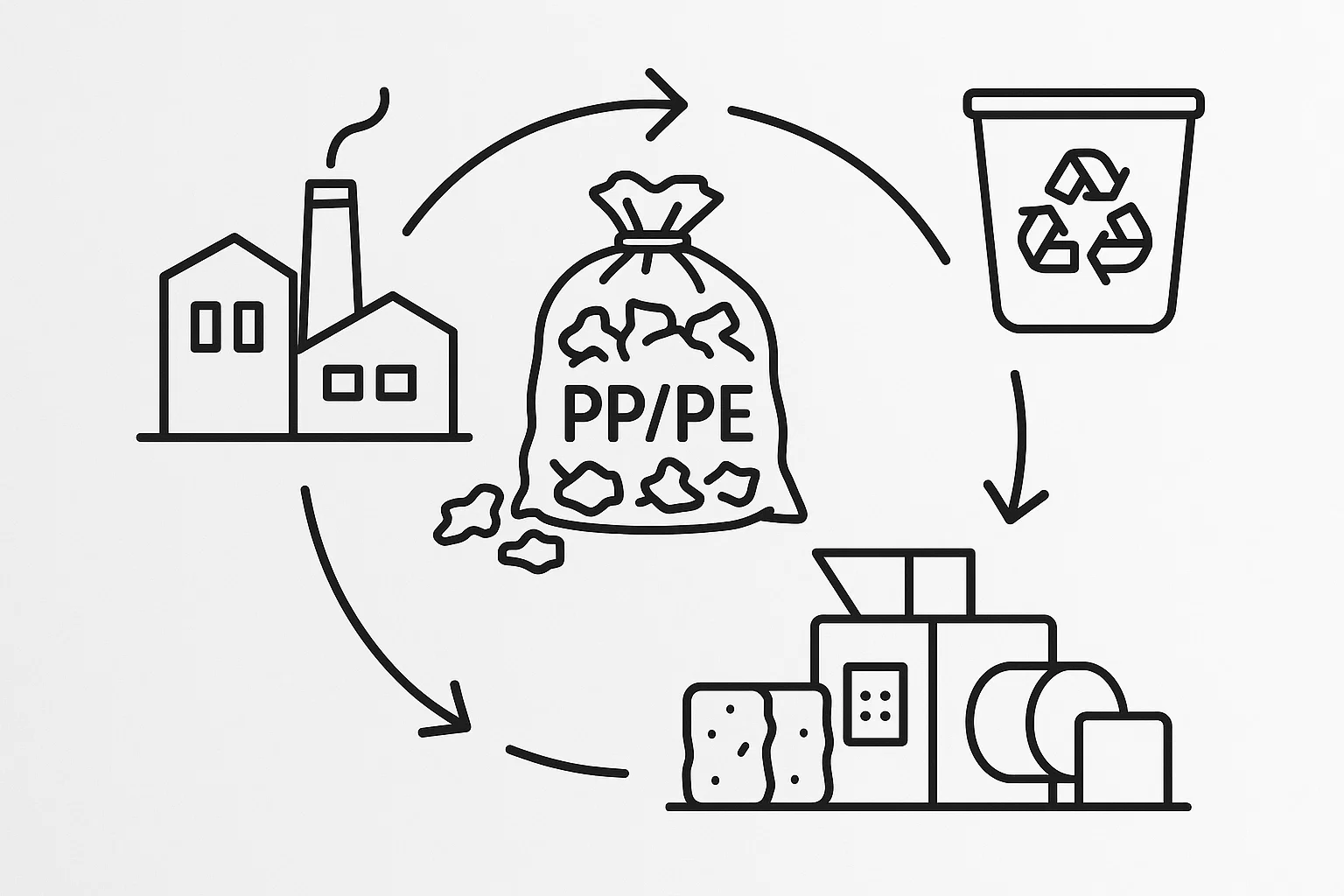

Where Densifying Fits in Your Recycling Line

Densifying is the critical bridge between washing and pelletizing. A typical state-of-the-art workflow looks like this:

- Shredding: Bales of film are broken down into smaller, manageable pieces.

- Washing & Separation: Contaminants like dirt, labels, and heavy plastics are removed.

- Densifying: The clean, wet film is squeezed, heated, and compacted into dense, dry granules. This is the key value-adding step.

- Pelletizing: The densified material is fed into an extruder to be melted, filtered, and cut into final, uniform pellets.

Is a Densifying Line Right for Your Operation?

If you’re looking to cut operational costs, improve the quality of your recycled materials, and create a more efficient, profitable recycling business, the answer is yes. Stop struggling with bulky, wet film and start producing a high-value, easy-to-manage product.

Our PP/PE Film Shredding & Densifying Line is engineered for reliability and peak performance, transforming your raw plastic waste into a valuable resource.