Blog

-

Lab Twin Screw Extruder

Our Mini Lab Twin Screw Extruder is the ultimate desktop solution for advanced polymer research and development. It combines an ultra-compact design with powerful PLC…

-

The Ultimate Guide to Recycling Soft Plastics: How to Profitably Process PP/PE Film

Soft plastics like PP and PE film are a major recycling challenge, often ending up in landfills. This definitive guide details the industrial pelletizing process,…

-

The Complete Guide to Recycled Plastic Pellets

Recycled plastic pellets are the key ingredient for a circular economy. Discover what these sustainable granules are, the different types available (like R-PET and R-HDPE),…

-

How Much Does a Plastic Pelletizing Machine Cost? [2025 Guide]

Learn about plastic pelletizing machine prices, from $10,000 to $500,000+. Explore factors, systems, and tips to choose the best equipment for your needs.

-

A Buyer’s Guide to Cooling Technology for Plastic Pelletizing Machines

Discover why the cooling stage is critical for producing high-quality recycled plastic pellets. This guide provides a detailed analysis of water cooling (strand, ring, underwater)…

-

Can EPS Foam Be Recycled? An Industry Guide to a Profitable Process

Despite being 98% air, Expanded Polystyrene (EPS) is 100% recyclable. The key to unlocking its value lies in overcoming its low density through specialised industrial…

-

How to Make Plastic Pellets: A Guide to Plastic Pelletizing Systems

Discover the plastic pelletizing process with Energycle’s cutting-edge systems. Learn key steps, equipment, and tips to produce high-quality plastic pellets for recycling.

-

How to Select the Most Suitable Plastic Pelletizer Based on Different Plastic Types

A detailed guide to selecting the right plastic pelletizer based on plastic type, MFI, and production needs. Improve pellet quality and recycling efficiency.

-

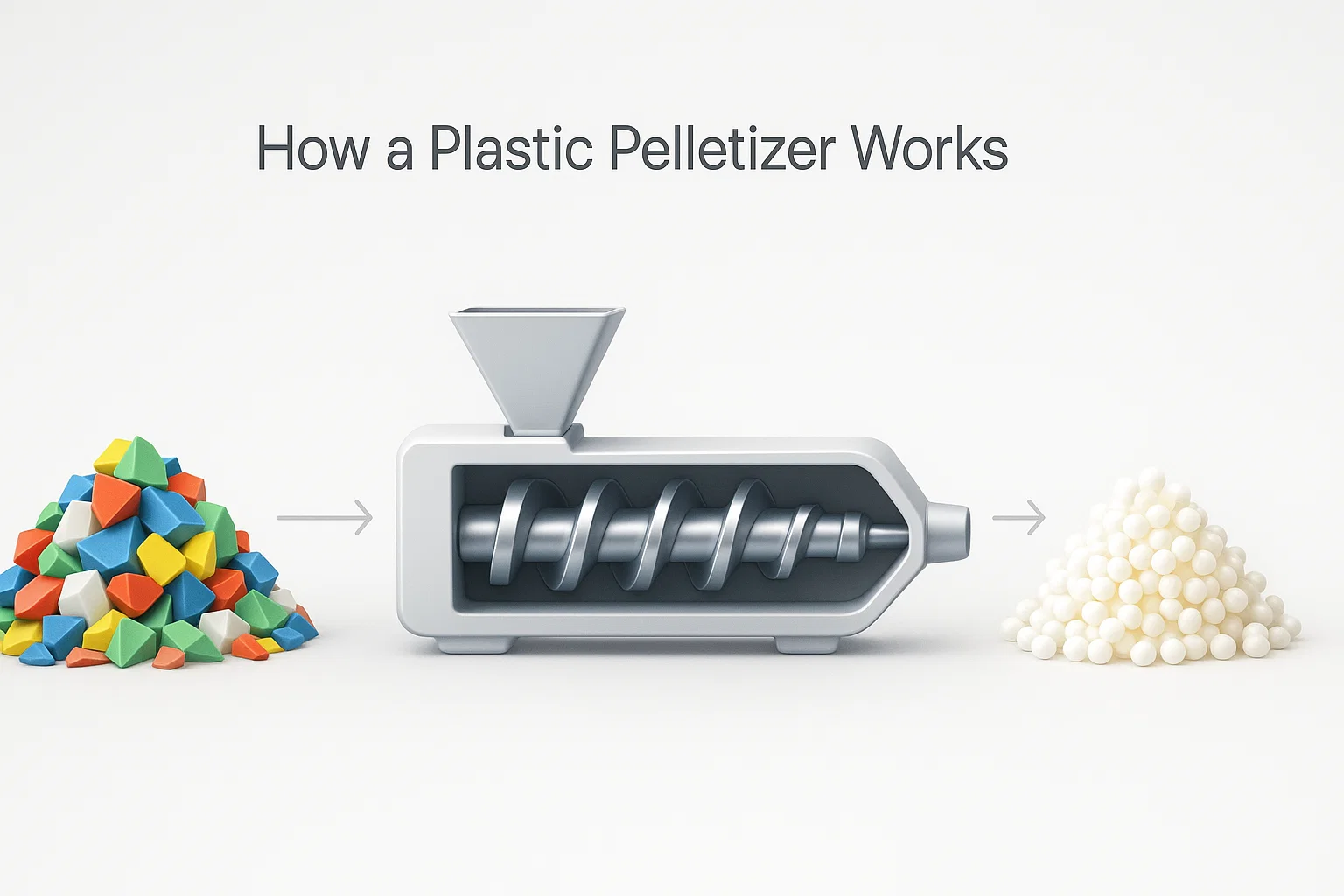

How Does a Plastic Pelletizer Work? A Comprehensive Guide

Discover how a plastic pelletizer works with Rumtoo’s expert guide. We break down the complete pelletizing process—from extrusion and filtration to cutting—to help industrial professionals…

-

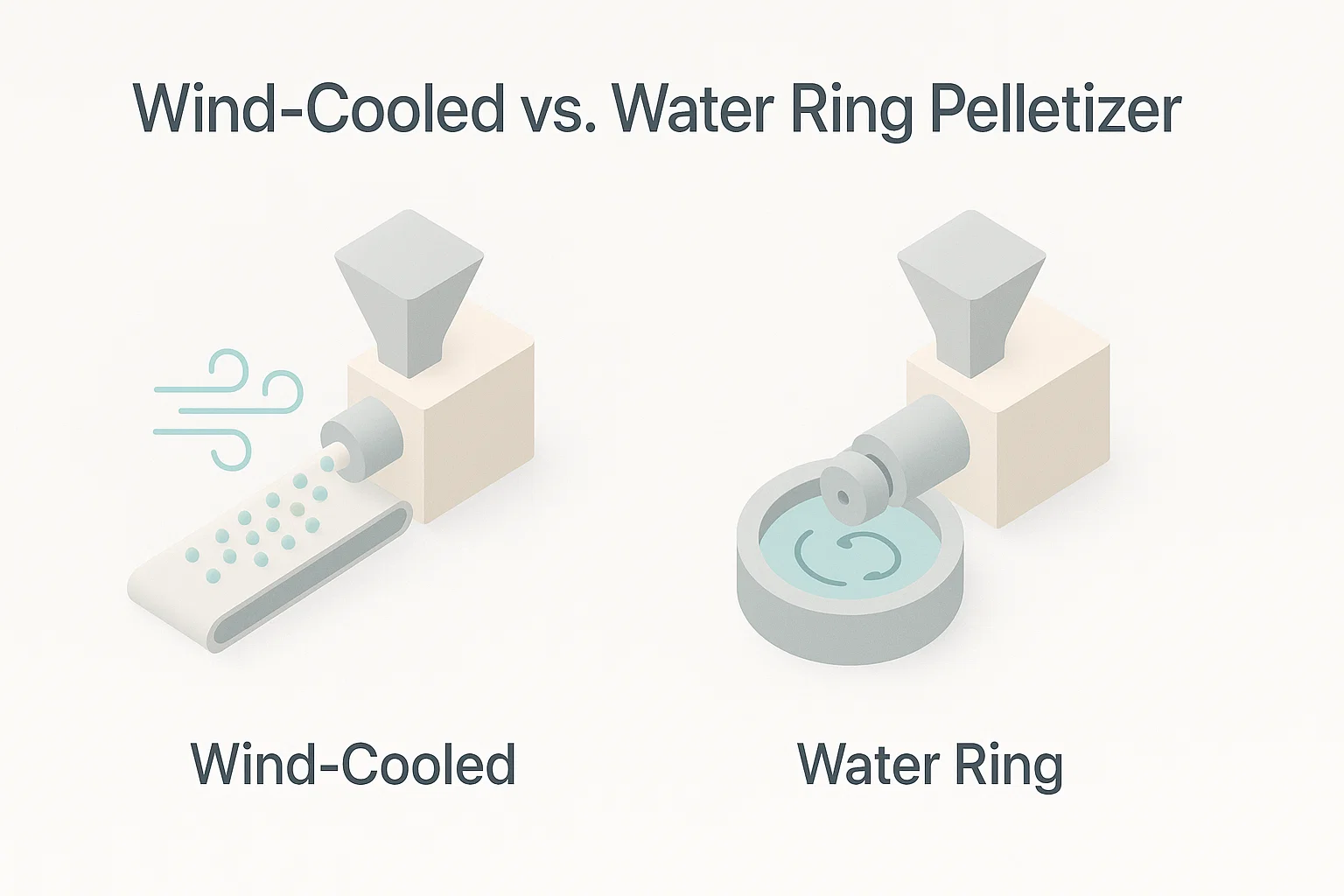

Wind-Cooled vs. Water Ring Pelletizer: A Complete Guide

This in-depth analysis compares the wind-cooled and water ring plastic pelletizer systems. We explore working principles, pros and cons, pellet quality, and cost-effectiveness to help…

-

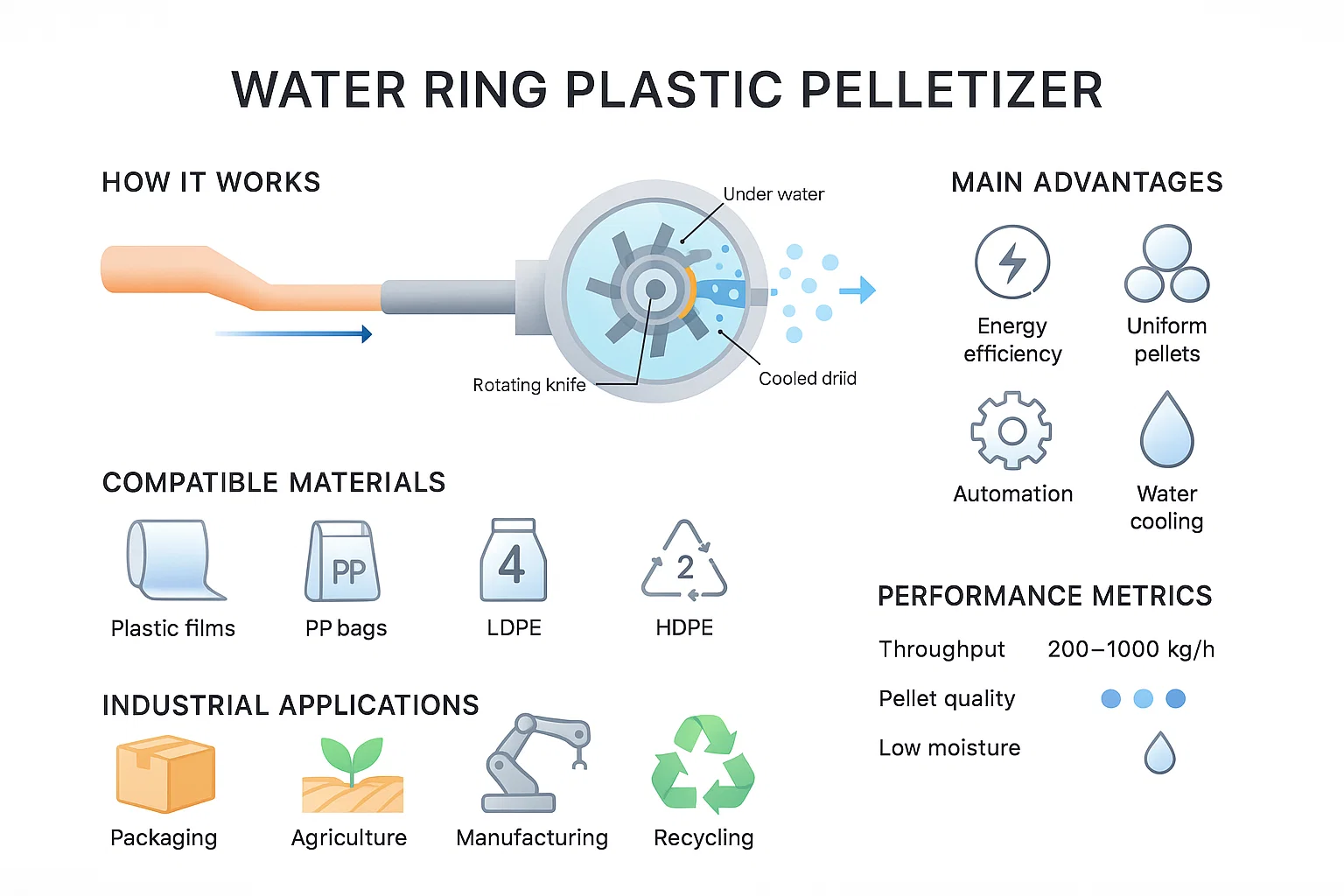

Water Ring Plastic Pelletizers: The Complete Guide for Industrial Recycling Equipment Buyers

Water ring plastic pelletizers offer a high-efficiency solution for converting plastic waste into premium recycled pellets. Learn how this technology supports scalable, automated, and sustainable…

-

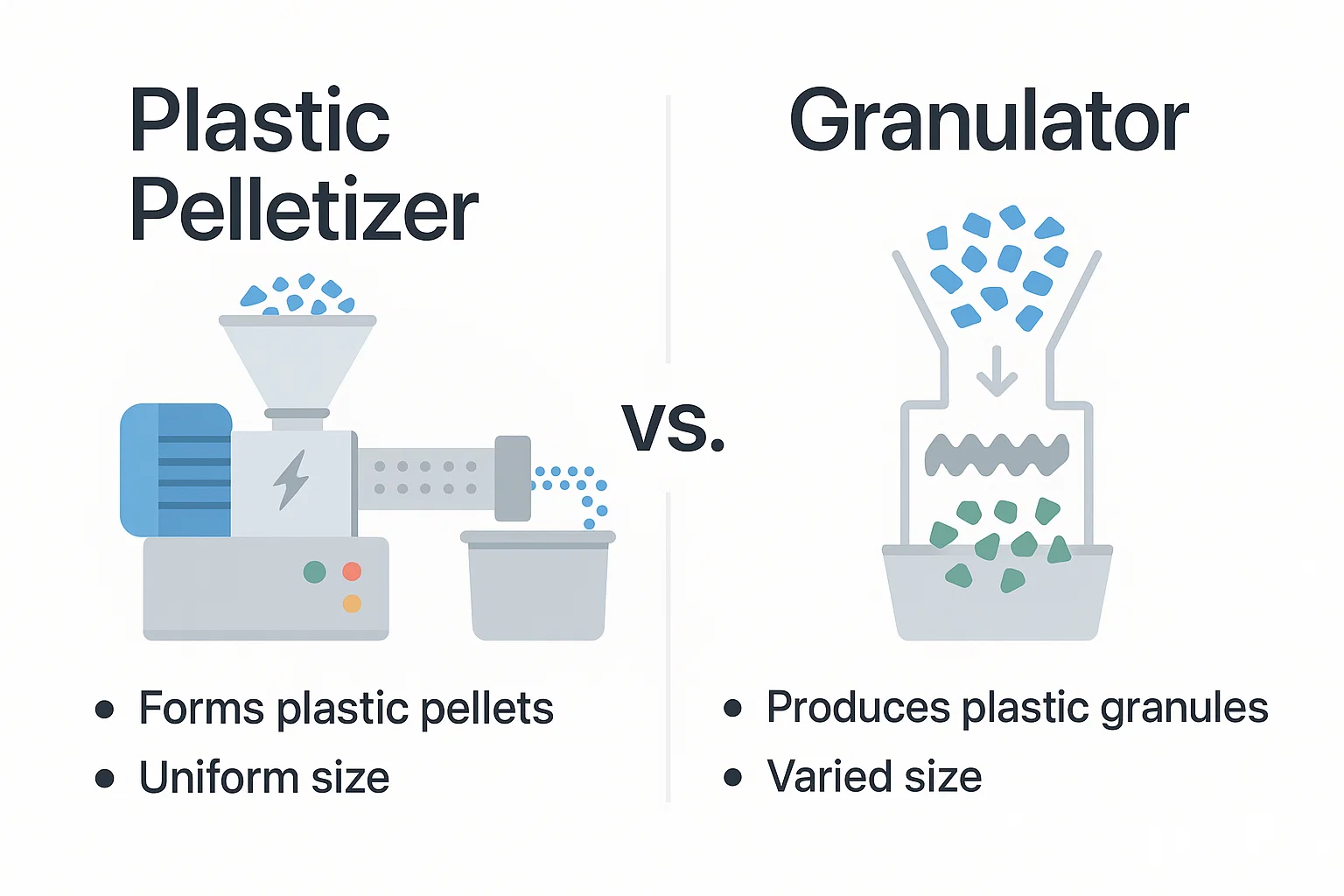

Pelletizer vs. Granulator: A Crucial Distinction in Plastic Recycling

What is the real difference between a plastic pelletizer and a granulator? While both are used for size reduction, one processes molten plastic into uniform…

-

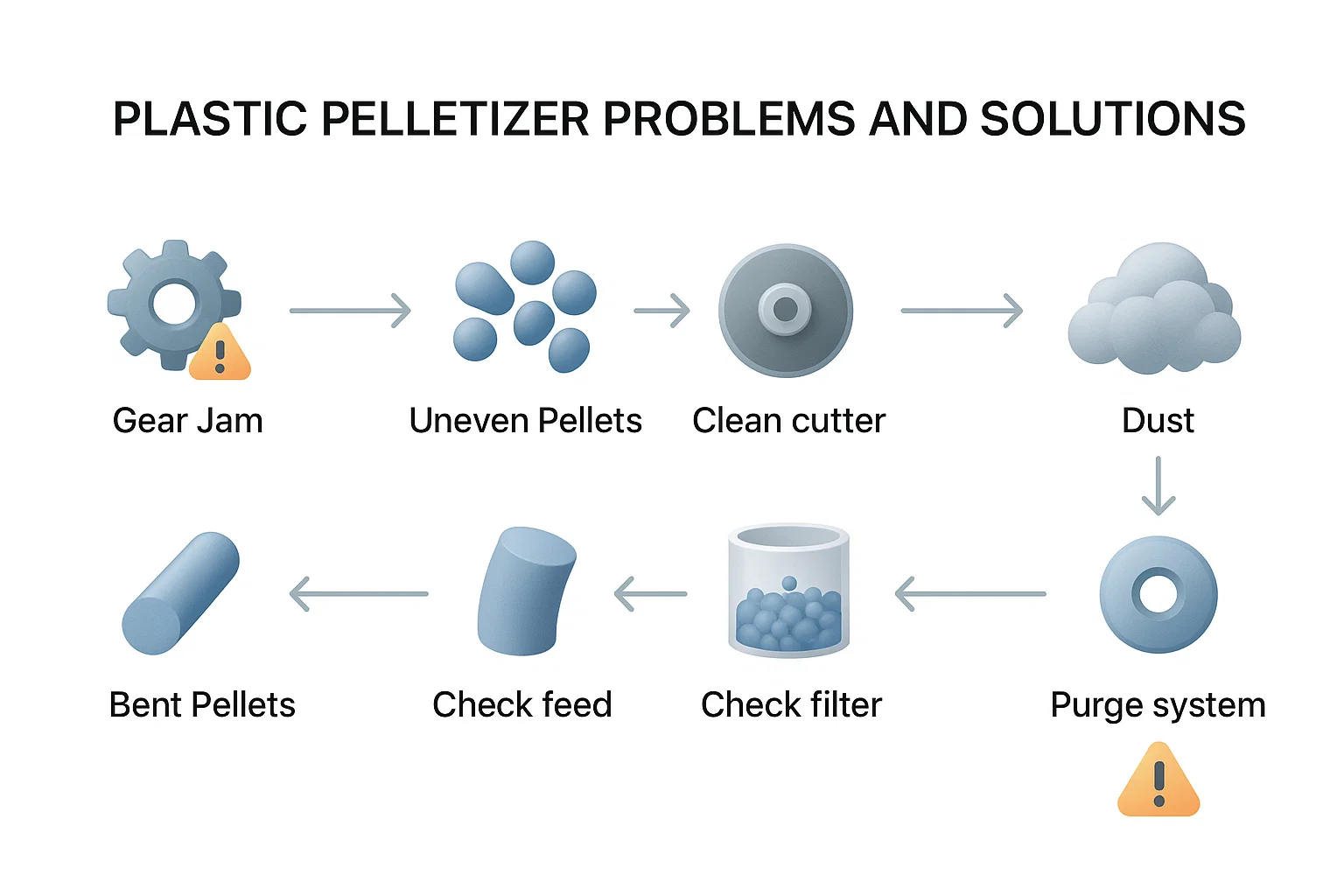

7 Common Plastic Pelletizer Problems and Solutions

By proactively managing feeding consistency, thermal control, cutting precision, and equipment integrity, pelletizer operators can minimize defects and ensure high-quality, continuous pellet production with minimal…

-

PP Raffia & Textile Regeneration: A Plastic Pelletizer Guide

Transform post-industrial and post-consumer PP raffia and textile waste into a valuable asset. This guide details the essential regeneration process, emphasizing the role of an…

-

Transform Your Foam Waste: The Ultimate Guide to EPS Foam Cold Press Machines

EPS Foam Cold Press Machines revolutionize foam waste management by compressing materials like Styrofoam into dense blocks—reducing costs and supporting sustainability. Learn how they work…

-

How to Choose the Right Plastic Pelletizing Machine for Efficient Recycling

Not all plastic pelletizing machines are created equal. This comprehensive guide helps you choose the right one based on your plastic waste type, production goals,…

-

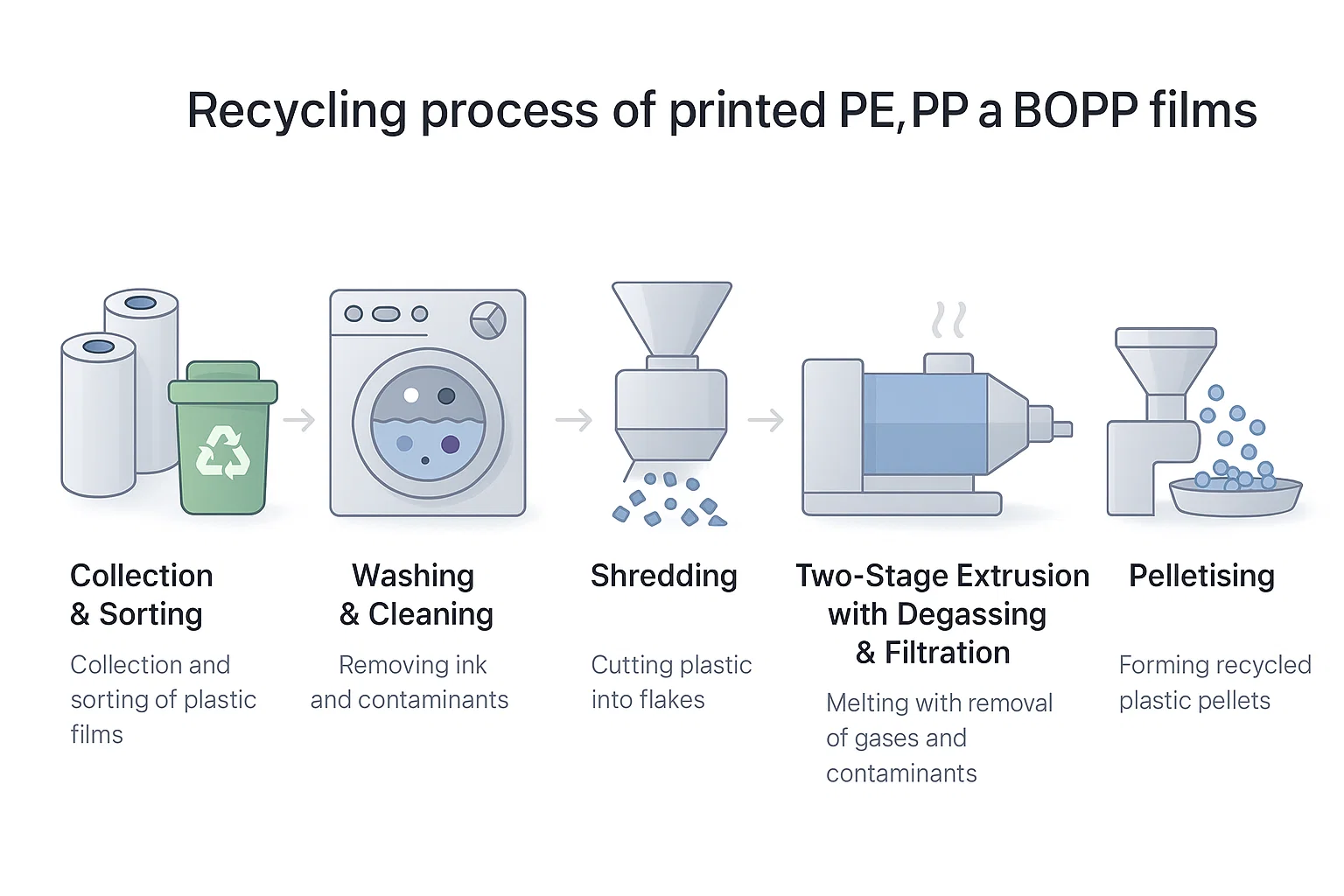

Efficient Recycling of Highly Printed PE, PP, and BOPP Films

Recycling highly printed PE, PP, and BOPP films requires advanced equipment to remove inks and contaminants. Learn how technologies like Repro-Flex Plus enable the production…

-

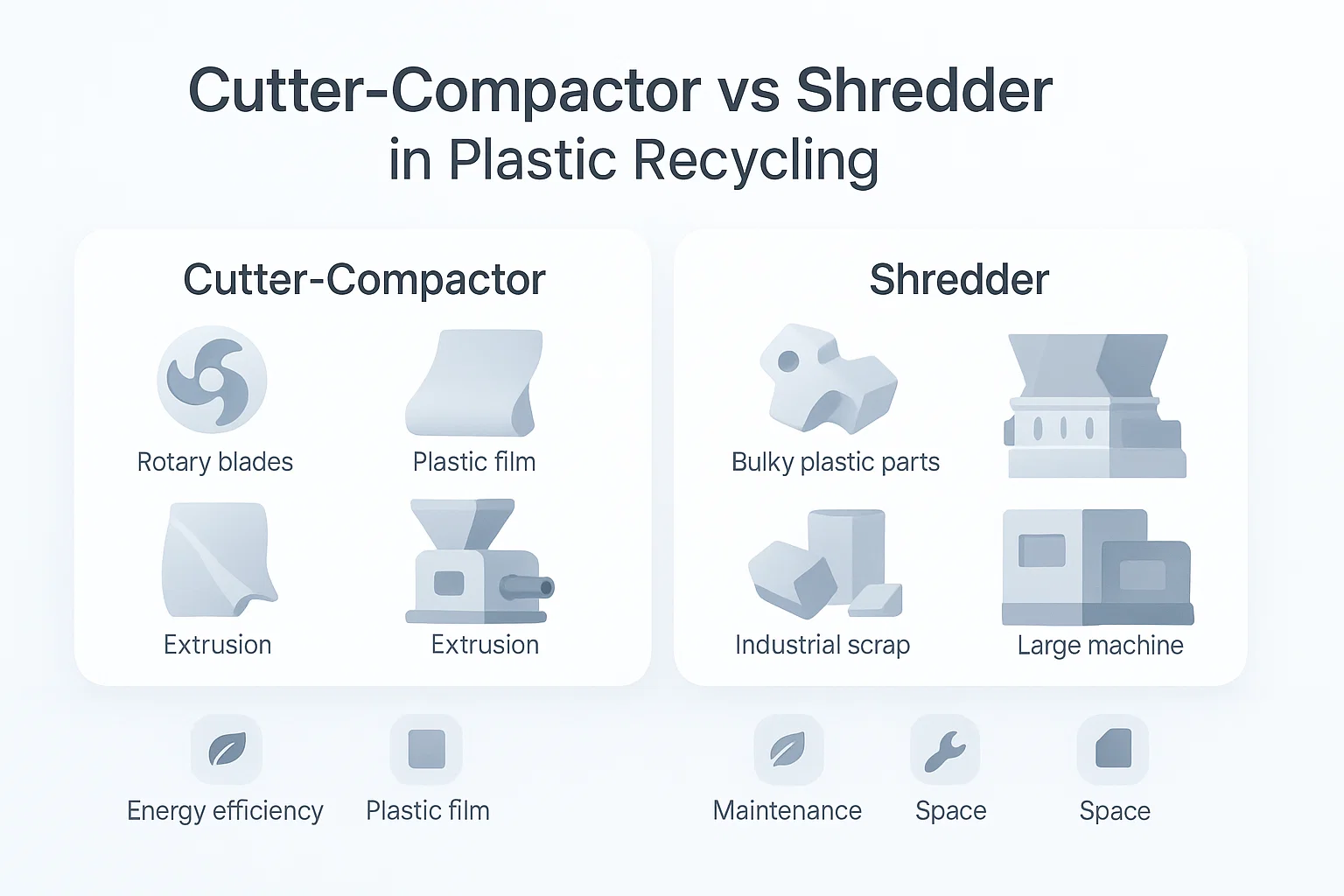

Differences Between Cutter-Compactors and Shredders in Plastic Recycling

Learn the core differences between cutter-compactors and shredders—how they process plastic, what materials they handle, and which fits your recycling goals best.

-

Types of Waste Plastics Suitable for Single-Stage Recycling Pelletizing Machines

Single-stage recycling pelletizing machines efficiently convert waste plastics like PE, PP, and more into reusable pellets. This guide covers the types of plastics, input forms,…

-

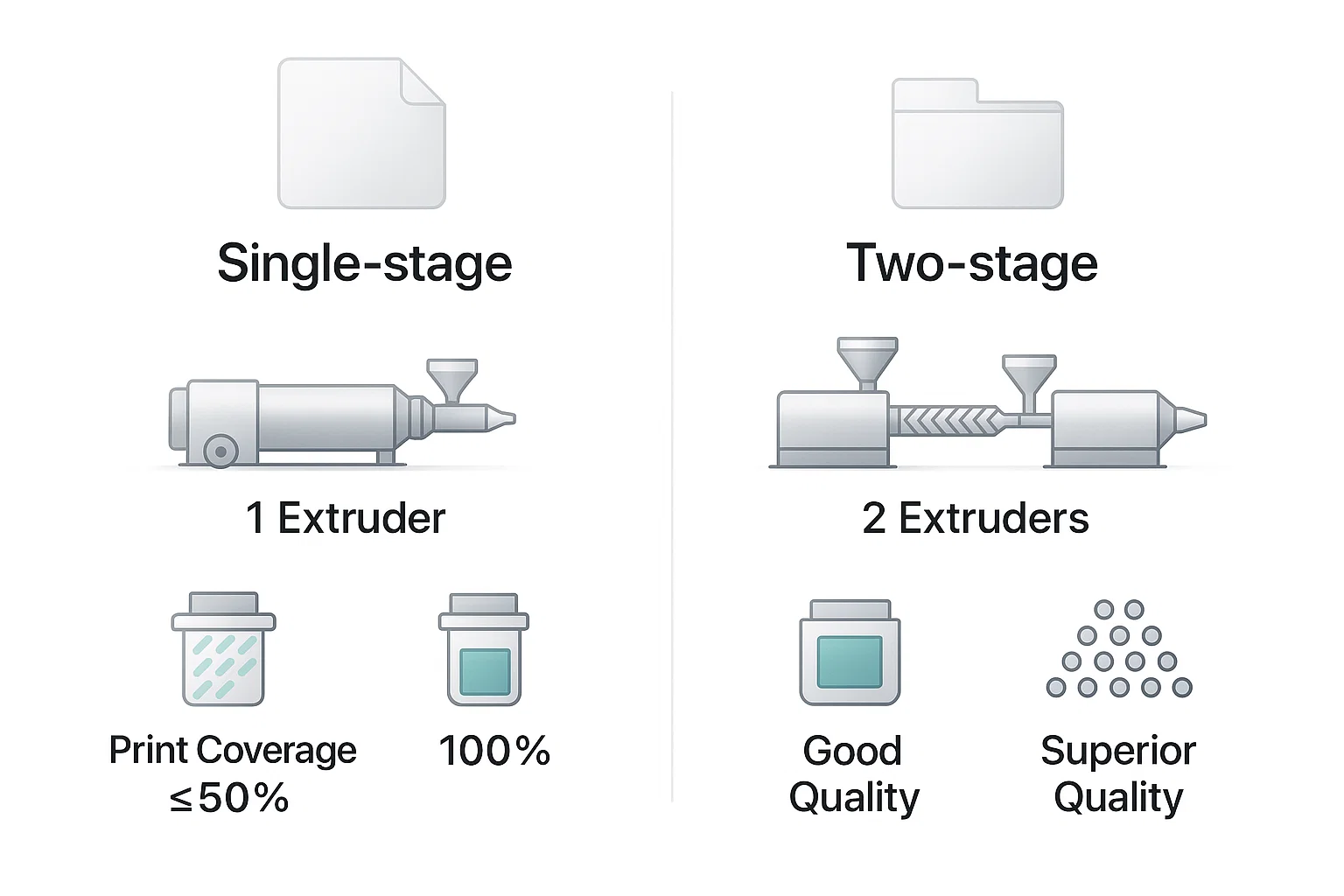

Single-stage vs. Two-stage Plastic Recycling Machines: Key Differences Explained

Compare single-stage and two-stage plastic recycling machines by structure, degassing, filtration, and processing capability. Choose the right solution for your waste material needs.

![How Much Does a Plastic Pelletizing Machine Cost? [2025 Guide]](https://plasticpelletizer.net/wp-content/uploads/2025/06/How-Much-Does-a-Plastic-Pelletizing-Machine-Cost-2025-Guide.webp)