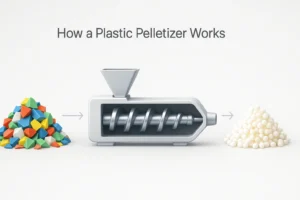

PP HDPE Rigid Plastic Flake Pelletizing System

High-Purity PP/HDPE Rigid Flake Pelletizing System Convert post-industrial and post-consumer rigid plastic waste into premium, uniform pellets. Our two-stage granulation system is engineered for maximum efficiency, superior purity, and a rapid return on your investment, powering the circular economy. Request a Quote From Flake to High-Value Pellet: A 6-Step Process 1 Automated Feeding Washed and …

![How Much Does a Plastic Pelletizing Machine Cost? [2025 Guide]](https://plasticpelletizer.net/wp-content/uploads/2025/06/How-Much-Does-a-Plastic-Pelletizing-Machine-Cost-2025-Guide-300x200.webp)